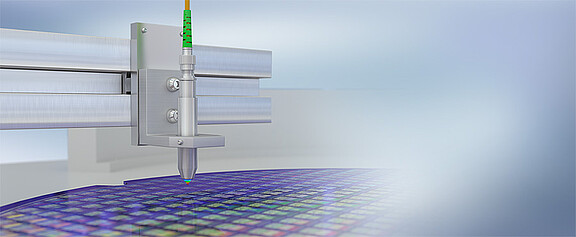

In the semiconductor industry, optics or aviation, measurements under vacuum conditions are part of everyday life, but also place the highest demands on sensor technology. Micro-Epsilon offers both catalog sensors and specially developed sensors that…

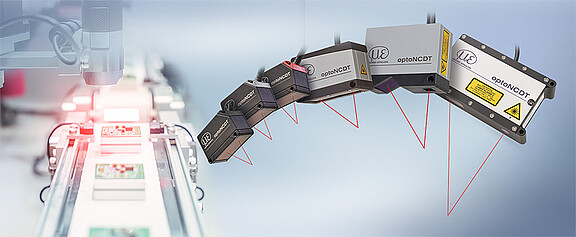

With the optoNCDT laser sensors, Micro-Epsilon offers a broad portfolio with measuring ranges from 2 to 1000 mm. This makes these sensors suitable for a variety of applications in a wide range of industries.

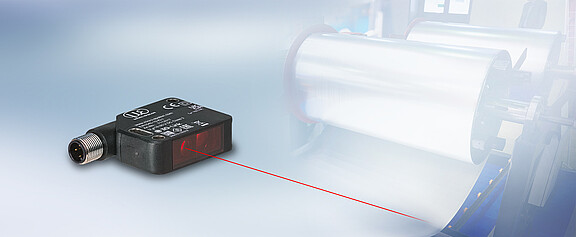

The optoNCDT ILR1040 laser distance sensor impresses with its compact design and high precision in a wide range of applications – from automation and logistics to renewable energies and construction machinery. Its high stability even under changing…