- Micro-Epsilon

- Measuring systems

- Measuring systems for the battery production

- Other applications

Measurement tasks in the battery production

Sensors from Micro-Epsilon are used throughout the entire manufacturing process. They perform various measurement tasks for machine monitoring, thickness control and quality assurance.

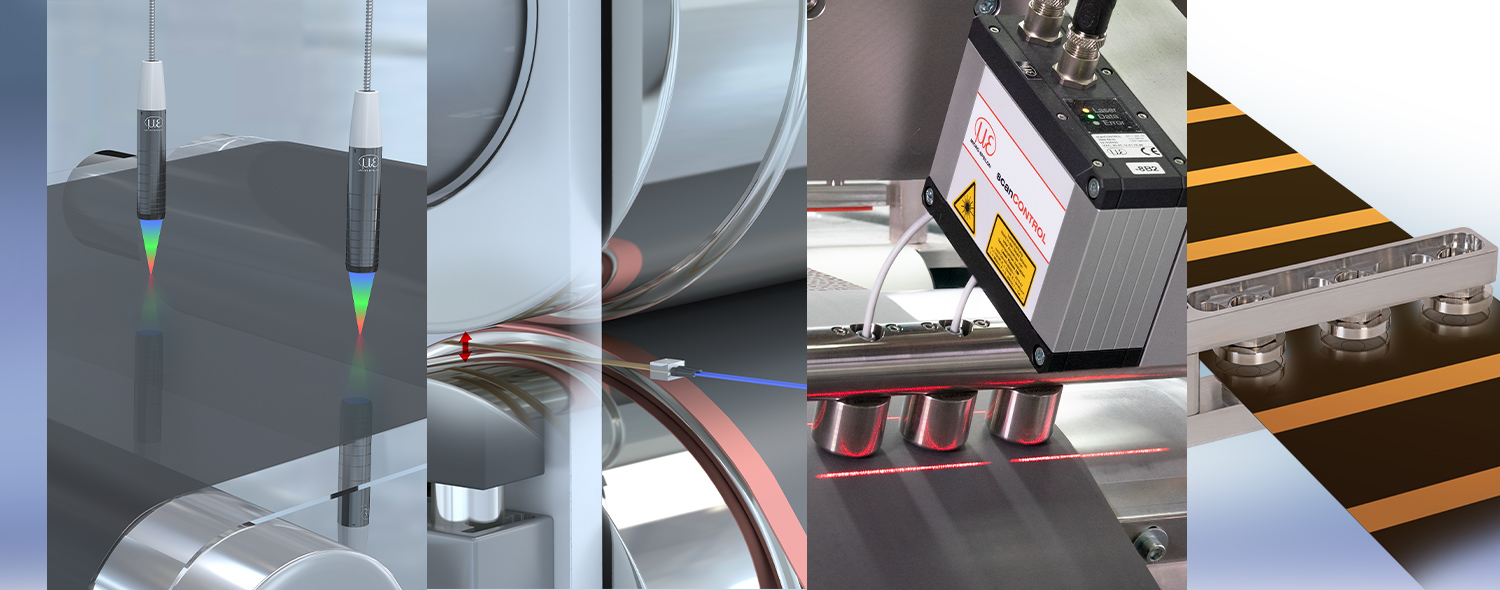

Roller gap measurement with calenders

Capacitive flat sensors are used for monitoring and controlling calender and coating rolls. These are available in various designs and detect the roller gap with micrometer accuracy. These compact sensors can be integrated into confined installation spaces to measure directly against the rollers or the roller suspension. Their high temperature stability allows them to be used in high ambient temperatures.

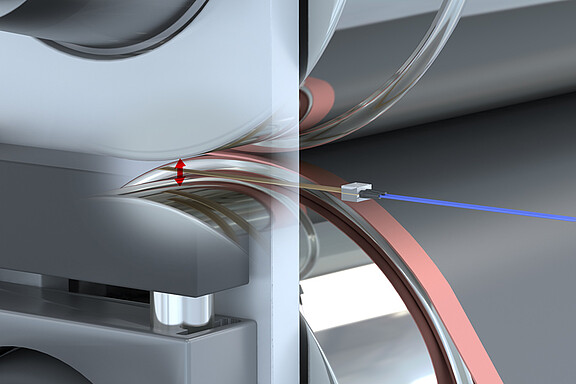

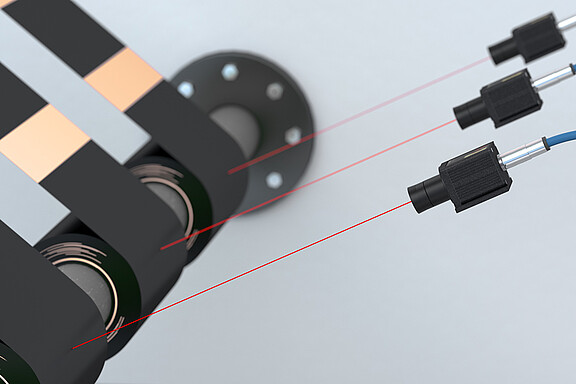

Edge monitoring of battery film

During the production of battery cells, electrode and separator films must be guided reliably. Optical optoCONTROL micrometers detect the required edge position for web edge control with high accuracy. Operating several micrometers enables the concurrent detection of the web width.

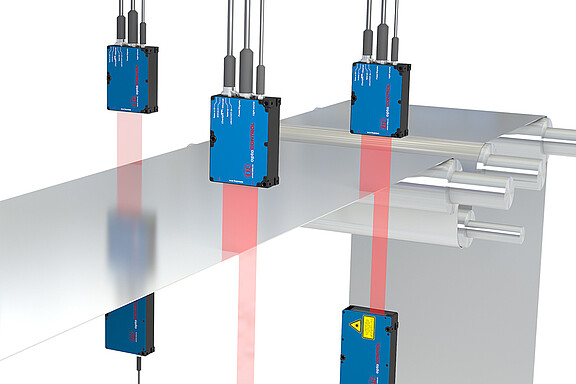

Monitoring the coil unwinding process

optoNCDT ILR2250-100 laser distance sensors monitor the unwinding and winding of coils. As the diameter continuously increases or decreases respectively, the distance between the coil and the sensor changes. This distance change is reliably and precisely monitored by the sensors. The integrated AUTO measurement mode enables reliable detection even on reflective surfaces and mat coatings.

Temperature measurement during the formation process

Especially during initial charging, temperature development is a decisive parameter and is therefore monitored using thermal imaging cameras. These provide an insight into the temperature distribution and possible short circuits. The thermoIMAGER thermal imaging camera is designed for demanding industrial serial applications. The powerful software monitors hot and cold spots automatically and outputs measured values to a control unit. The camera is able to focus on and monitor up to three measuring fields simultaneously on a continuous basis.

Monitoring the edge curvature (Heavy Edge) after cutting

Curvatures and deformations often occur after longitudinal cutting of the film. In order to detect these deviations reliably, laser profile sensors from Micro-Epsilon are used. These are placed over the edge of the film and continuously detect the profile. Due to their high resolution and insensitivity to reflecting surfaces, these sensors provide stable measurement results and highly accurate 2D profiles, from which 3D point clouds can also be generated.