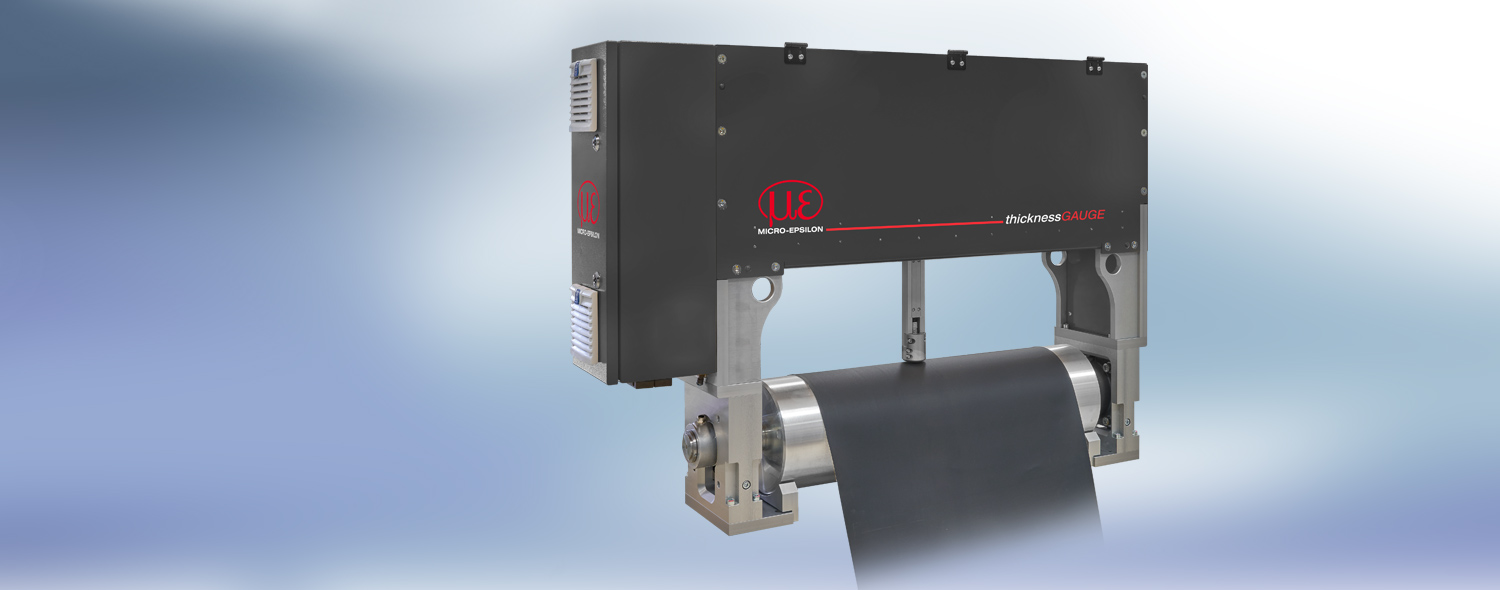

thicknessGAUGE O.EC

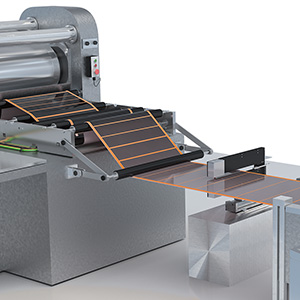

The thicknessGAUGE O.EC is a compact inline measuring system in a stable O-frame design with an aluminum roller and an integrated control cabinet. The system is used for precise thickness measurements of plastic strips and coatings up to 3 mm material thickness and web widths up to max. 1250 mm. To obtain a cross profile of the material thickness, the sensor is traversed over the film. Keeping the sensor fixed at a particular position enables a thickness profile to be generated.

Integration takes place in complete production lines, e.g., in plastics production and battery film production. The systems can be integrated into new plants or retrofitted directly into existing plants.

Characteristics

- Sensor used: combiSENSOR

- Measuring width: 500 / 750 / 1000 / 1250 mm

- Accuracy: ± 0.3 µm

- Measuring rate: 3.9 kHz

- Traversing measurement or fixed track measurement

- 24 V supply for the entire system

- Highest precision at an attractive price

- Suitable for OEMs

The thicknessGAUGE O.EC uses a combiSENSOR for thickness measurements, which enables submicrometer accuracy and high signal stability at the same time. The combiSENSOR combines a capacitive sensor with an eddy current-based inductive sensor. Both sensors measure from the same side in the direction of the aluminum roller. The capacitive sensor uses the dielectric constant of the non-conductive material to determine the distance to the topside of the target, while the integrated eddy current sensor detects the distance to the aluminum roller. The difference between both signals determines the thickness of the material.