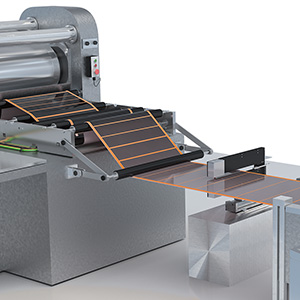

Process-reliable distinction of black tones in battery production

The production of lithium-ion batteries requires maximum precision. In this ultra-modern manufacturing process, carrier films are combined with an anode and a cathode to form an energy cell. The anode consists of a copper film coated with a graphite layer in deep black. The cathode has an aluminum film with a deep black lithium metal oxide coating. The two shades of black can hardly be distinguished from each other. However, this is of great importance to ensure the proper functioning and reliability of the batteries. The color distinction can be used to check whether the electrodes, which are separated by a separator film, have been positioned correctly.

The colorSENSOR CFO200 color measuring system in conjunction with the innovative CFS2-M11 circular sensor reliably solves this measurement task and makes it possible to distinguish color nuances. The measurement takes place in real-time, with high precision and high speed. This makes it possible to produce high quality batteries and save time and valuable resources. The high precision color measuring system works with a true-color chip and recognizes the differences between the black tones with high precision at < 30 kHz. Implementation in existing production systems is simple and time-saving.