Precise surface inspection and geometry measurement

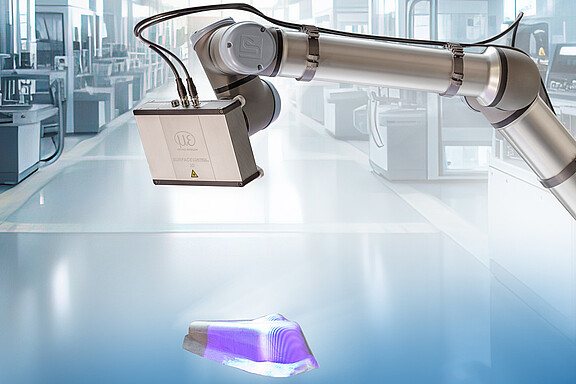

3D sensors revolutionize the acquisition of three-dimensional data by setting new standards in image processing. As they precisely capture entire objects in just one recording process, they significantly outperform conventional sensor technologies. 3D snapshot sensors are used in many industries, including robotics, automation and quality control.

Advantages of 3D snapshot sensors

- Real-time 3D data: Fast and reliable, ideal for dynamic applications.

- High precision: Acquisition of accurate depth information and surface details.

- Flexibility: Can be used in various environments and on a wide range of materials.

- Ease of integration: Compatible with modern image processing systems and easy to integrate into existing systems.

What are the advantages of 3D snapshot sensors for modern applications?

3D snapshot sensors offer clear advantages for precise and fast 3D measurements that are processed in real time. The non-contact and wear-free detection of objects makes these sensors ideal for sensitive and demanding fields of application. They are indispensable in precise geometry measurement, especially in automation and robotics.

What are 3D snapshot sensors and how do they work?

A 3D snapshot sensor is a special type of sensor that captures the entire geometry of a scene in a single snapshot. This enables precise, three-dimensional recognition of shapes, volumes and surface structures in real time.

How surfaceCONTROL 3D sensors surpass conventional image processing

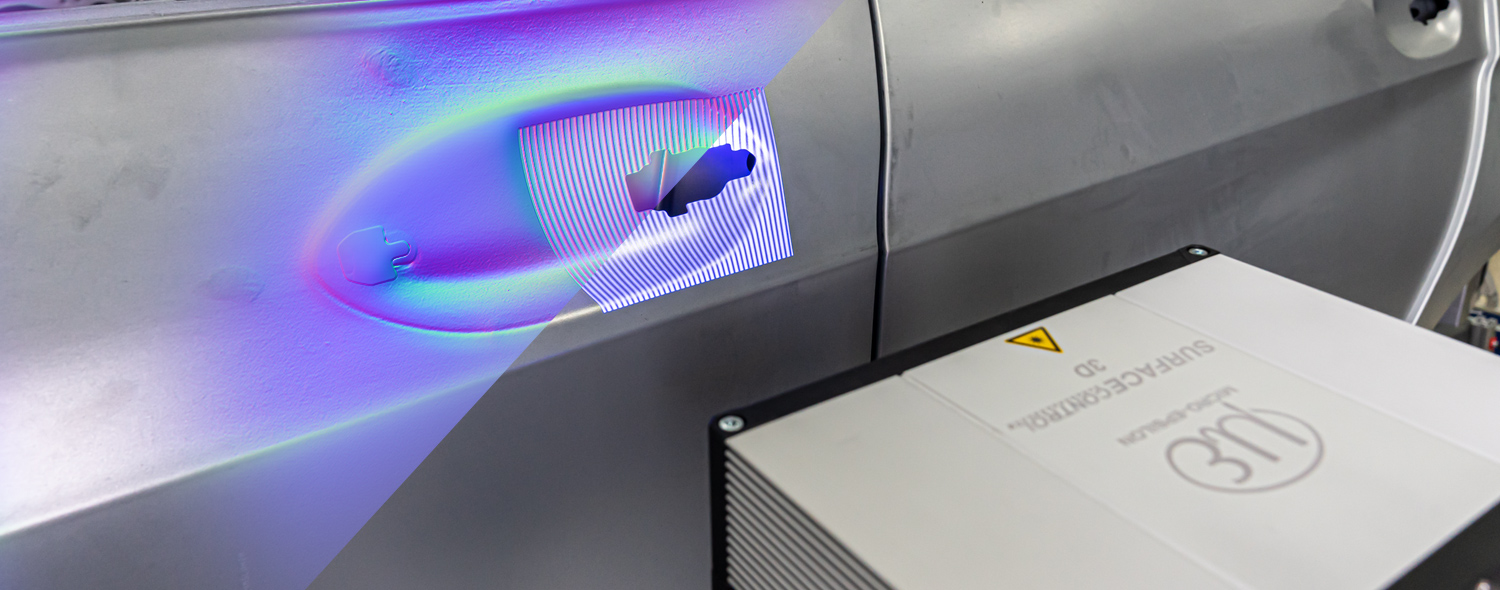

Conventional 2D image processing cameras do not recognize depth information when capturing images. If the position of a measuring object changes, errors can occur during evaluation. The advantage of 3D sensors lies in the high-precision detection of height differences. Due to the additional height information generated, the 3D sensors from Micro-Epsilon automatically compensate for errors caused by changes in height. As a result, they are much more reliable than image processing cameras even with objects in different positions.

FAQ

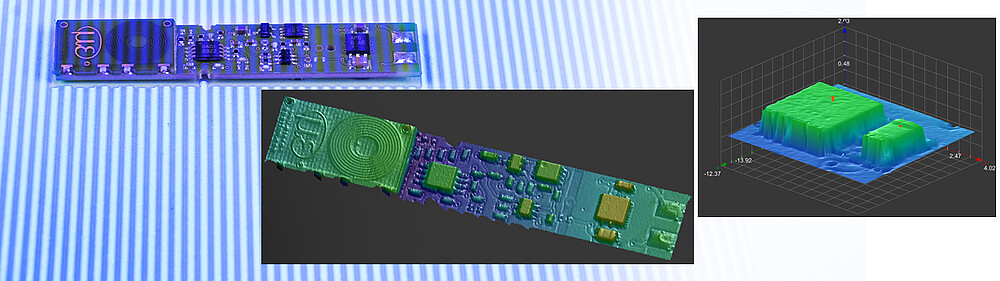

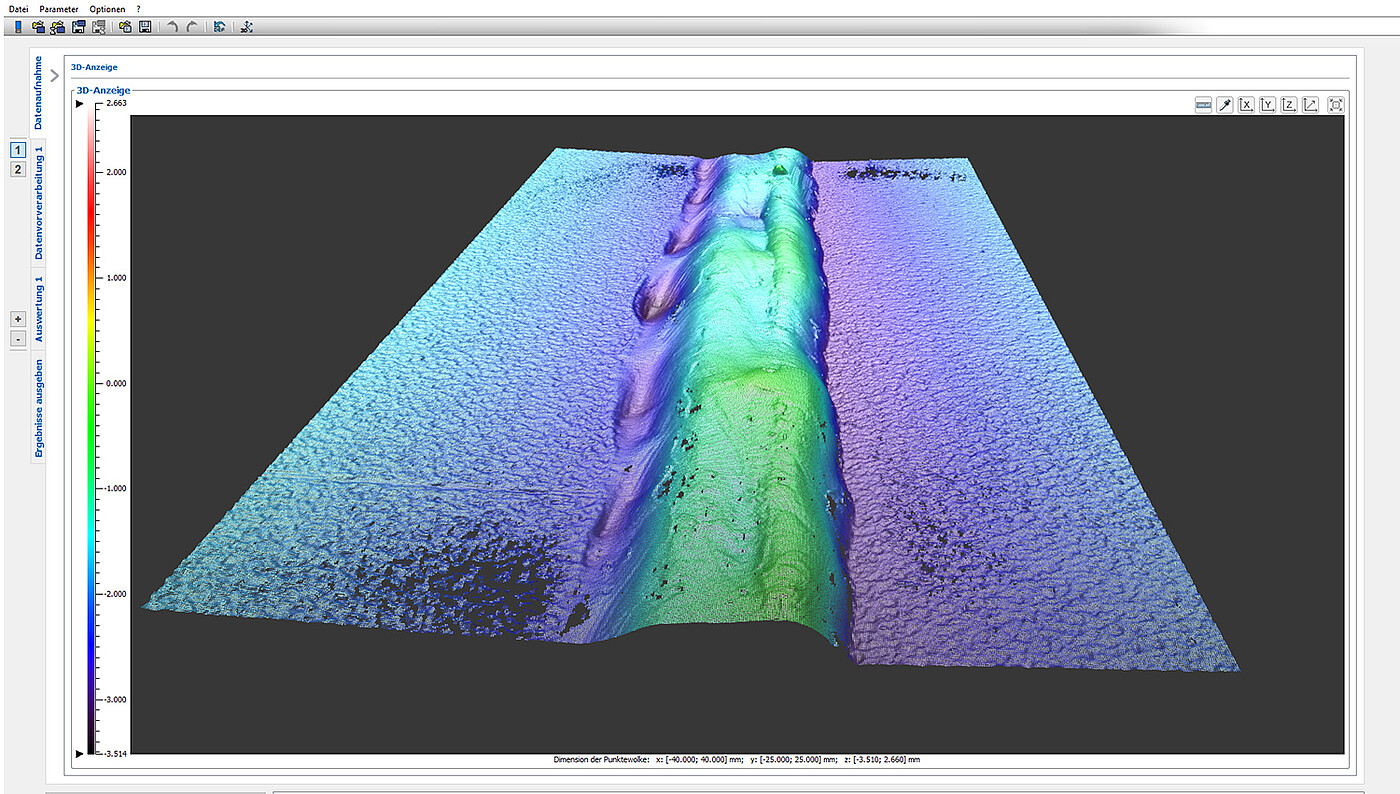

3D sensors from Micro-Epsilon use the principle of fringe light projection to detect diffusely reflecting surfaces and to generate a 3D point cloud. This point cloud is subsequently evaluated in order to recognize geometry, extremely small defects and discontinuities on the surface. 3D snapshot sensors are available with different measurement areas and performance data. The 3D snapshot sensors from Micro-Epsilon are designed for measurement tasks in industry and automation.

3D sensors are used in numerous industries and fields of application.

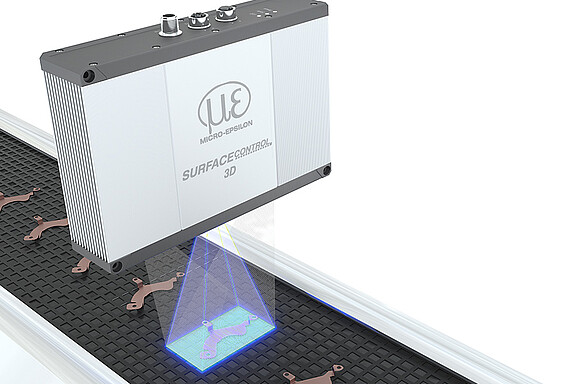

They can be used on the rotary indexing table, on the robot or integrated into a machine. On the conveyor belt, the 3D sensors inspect the 3D geometry using the Stop&and&Go method. 3D sensors typically measure geometry, presence, position and surface.

Depending on the sensor type, different measuring ranges are available, allowing for large objects to be detected, too.

3D sensors such as the 3D snapshot sensors from Micro-Epsilon generate a 3D point cloud in one shot.

3D laser scanners evaluate individual profiles. Consecutively arranged, these profiles form the 3D point cloud.

3D sensors from Micro-Epsilon are equipped with standard interfaces and can be easily integrated into existing automation systems and software solutions. Our sensors offer flexible connection options and software interfaces for seamless integration.

Rely on precision and efficiency: 3D snapshots for your industry

We offer you comprehensive advice and a selection of 3D sensors that perfectly match the requirements of your application. Optimized for a wide range of applications, our sensors are designed for fast and precise 3D measurement technology. Rely on state-of-the art technology for maximum efficiency in your production and logistics processes.

Get in touch with us for more information and individual advice on integrating our 3D snapshot sensors into your systems!