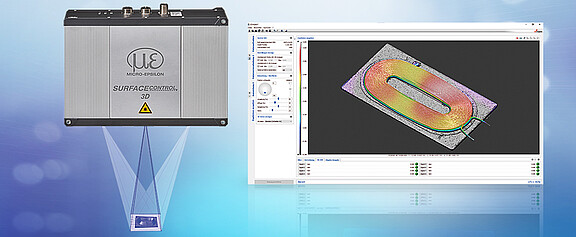

The new measuring range of 30 mm rounds off the surfaceCONTROL 3D 3500 series of geometry, shape and surface inspection systems for matt targets. This sensor is suitable for smaller objects with a maximum size of 31 mm x 19.5 mm. The working distance between the sensor and object is 130 mm. In addition to the high repeatability of 0.25 µm in the z-direction, this variant also offers precise xy-resolution of 8 µm. For measurements in harsh production environments or for use on robots, the sensor is embedded in a sturdy aluminum housing and certified with protection class IP67.

The surfaceCONTROL sensors are used in electronics production, among other things. Printed circuit boards are usually subjected to quality control to ensure that the quality of the conductor tracks, solder joints or surface coatings meets the specifications. Faults such as short circuits, interruptions or faulty solder connections can be easily detected. The SC35x0-30 is particularly useful for checking very small structures on assembled electronic modules. For example, it can be used to check that the smallest SMD components have been positioned correctly on the PCB. In addition to height measurement in the z-direction, the horizontal accuracy of the measurement is also crucial here.

The two new models of 30 mm and 240 mm extend the capabilities of the Micro-Epsilon 3D surface measurement technology portfolio from very small to large objects. The sensors deliver very high data quality. The surfaceCONTROL sensors can be used to implement solutions for inline quality control that use the 3DInspect software or proprietary software solutions as required.