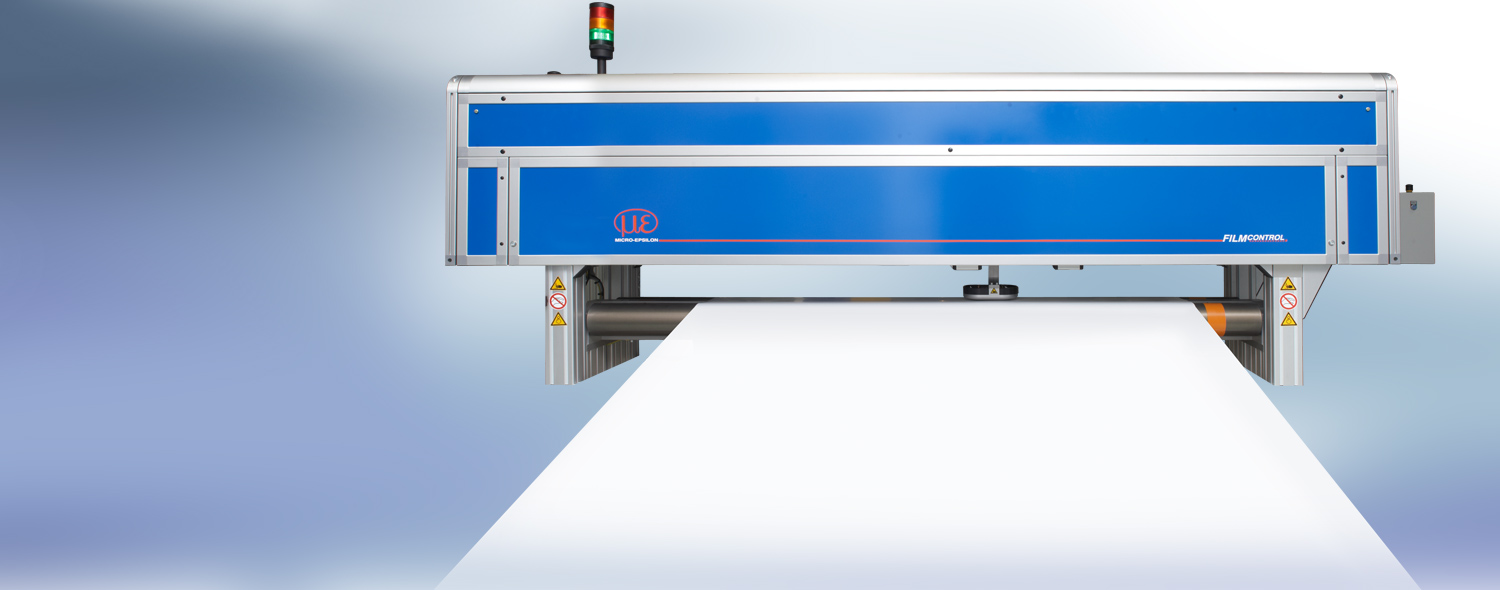

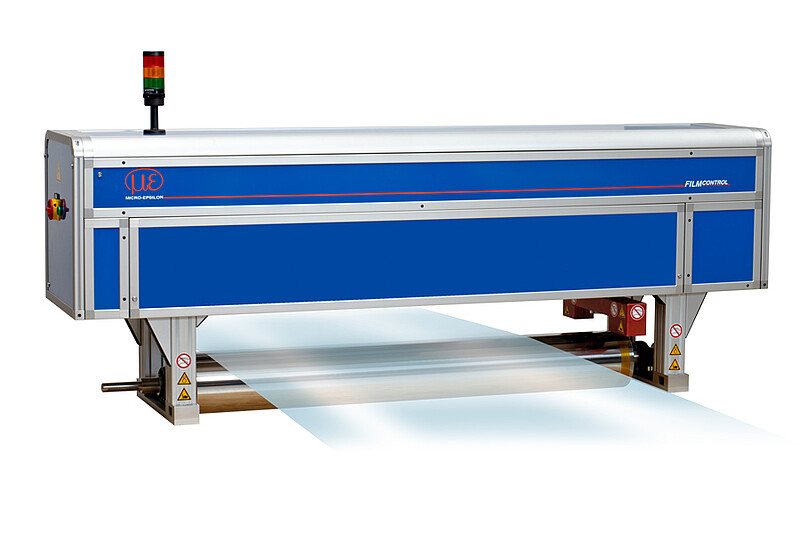

Non-contact thickness measurement in hot melt calender lines (thickness 0,03 mm to 6mm)

The systems of the FTS familiy offer thickness measurements with extreme stability and accuracy. Applying them in extrusion lines provides reliable measurement results in high precision and thus creates the basis for controlling the production process and eventually the quality achieved.

Advantages:

- Reduced consumption of raw materials goes along with increased quality

- Adaptive traversing speed

- Emission-free measuring technology

- Easy adaption in production lines

- Customized interfaces

Material parameter:

- Film thickness 30µm up to 6mm

- Film width up to 3000mm

- Material feed up to 14m/min

The products of the FTS family are designed as C frame and O frame systems, equipped with extreme precise capacitive and optical measurement technology. Parasitic distance effects of the measurement are eliminated with different compensation sensors. This procedure ensures highest precision in measurement and control.

The FTS 8101.EC O-frame is based on the combisensor principle equipped with non-contact capacitive sensors. The distance between sensor and film is measured with the capacitive sensor. The eddy-current sensors ensures the thickness signal by a reference measurement to a second target. The system can be integrated in the flat layer section.

Features:

- 100% non-contact measurement principle

- Resolution <0.1µm

- Adaptable traversing speed

The BTS 8101.EO O-frame is based on the combisensor principle. The system is equipped with a non-contact capacitive sensors and a Thrubeam sensor which are integrated in a traversing frame.

The eddy current sensor measures the reference distance to the measurement roll‘s metal surface. The distance from the film surface is measured by the Thrubeam sensor. Together with the reference signal the film thickness is calculated. This combisensor principle allows extreme precise measurements.

Features:

- Gap 22 mm

- Accuracy 3µm

- Material independent measurements