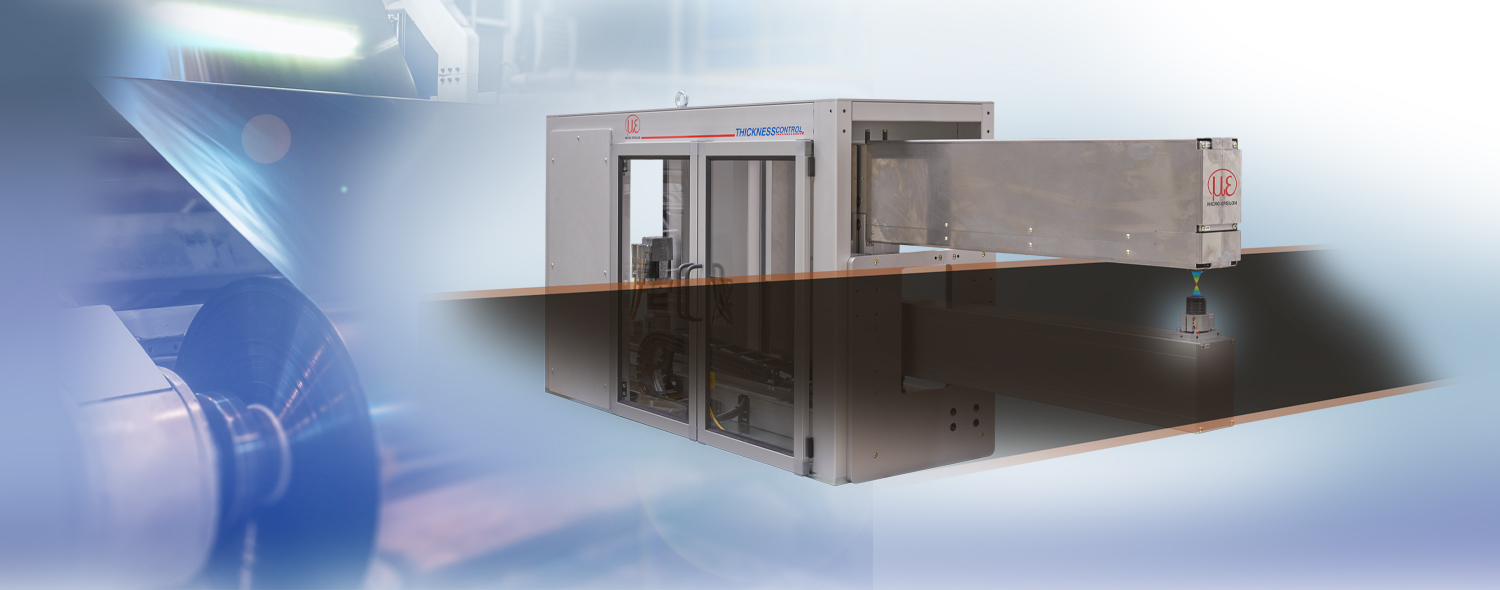

Inline measuring and inspection systems for the battery production

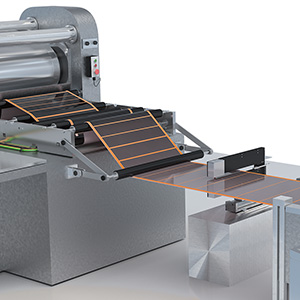

The quality of electrode film is crucial for increasing the performance of future battery generations. In order to generate higher energy densities, coating and calendering processes must be performed with the highest precision. Micro-Epsilon offers high-precision measuring systems for the thickness measurement of coated and uncoated battery film. These systems are equipped with high-resolution sensors and increase process stability, production speed and quality in modern coating lines.

Characteristics

- Largest technology portfolio in inline thickness measurement

- Turnkey measuring systems for high-precision film and coating thickness measurement

- Temperature-compensated measurement technology, ideal for wet and dry coating

- One main contractor from sensor technology to system integration

- In-depth industry and application knowledge

- On-site consulting and project management

Leadership in optical thickness measurement

Measuring systems from Micro-Epsilon can be equipped with different sensor technologies. In order to measure the thickness of the battery film, confocal chromatic sensors and capacitive displacement sensors are preferably used. Depending on field of application, measuring range and accuracy requirements, the best-suited sensor typ is selected for integration.