Sensors

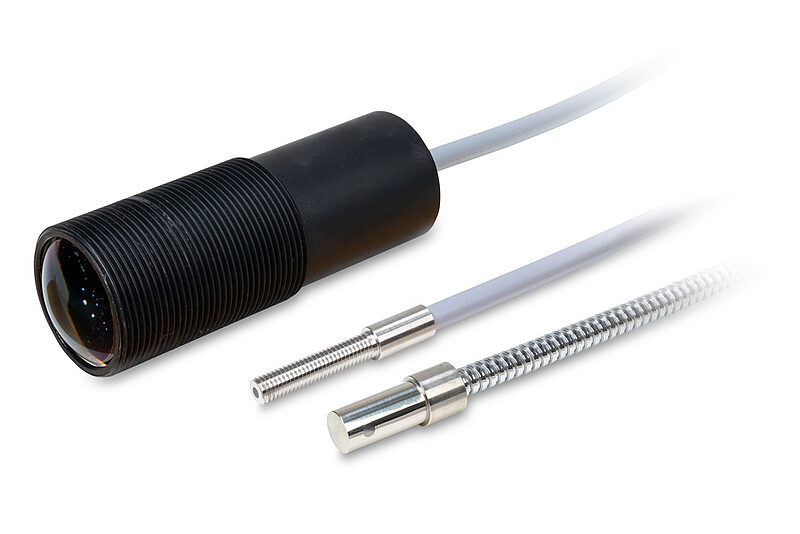

The operation of the colorSENSOR CFO controller requires sensors which are used at the measuring point. Depending on the measurement task, the sensors can be individually combined. Moreover, these high-quality sensors with glass fiber optics are characterized by small installation dimensions and robust materials. This makes them particularly suitable for mechanical stress and harsh ambient conditions such as high temperatures. Since the sensor head requires only little space, the sensor can also be used in confined conditions.

The angular illumination of the CFS1 enables a punctual illumination of the measuring object without influencing the surface. As a result, only the diffusely reflected portion of the surface color is detected. The measuring arrangement is best suited for high-gloss and diffusely reflecting surfaces, since the direct reflection (surface gloss) does not influence the measurement.

- For solid color, anti-reflective coating or chrome colors

- For high-gloss surfaces, diffuse reflection without gloss

- Max. working distance 125 mm (with reflective surfaces)

- Very precise positioning of the detection point

In combination with the performance of the CFO controllers, the ring illumination delivers even more precision thanks to uniform illumination. This compact combination can be used universally, but is also suitable for special solutions (customer-specific adaptations). The homogeneous illumination offers advantages especially on strongly structured or shiny metallic surfaces and provides highest precision in color differentiation of, e.g., white tones.

- For textiles, paper, metallic paint, sand, granules or masterbatch

- For structured and metallic effect surfaces

- Homogeneous illumination of the measuring point

- Max. working distance 100 mm (with reflective surfaces)

- Very precise positioning of the detection point

The transmission sensor can be used to measure transparent and translucent products such as filters, films and optical lenses. The measurement arrangement in transmitted light 180°: 0° provides even more precision in combination with the performance of the CFO controllers. Here, the distance variation between the test specimen and the receiver or illumination has no noticeable influence on the measurement result. The transmission sensor can be used universally, but is also suitable for special solutions (customer-specific adaptations).

- For films, glass, translucent liquids, PET or filter bottles

- For transparent surfaces

- Max. distance between receiver and transmitter unit 40 mm

- No exact positioning necessary

The reflex sensor, in combination with the performance of the CFO controllers, provides even more precise distinction of the surface characteristics of materials. The measurement arrangement in the reflective sensor of the transmitter and receiver in 0°: 0° enables quality control not only based on color, but also in combination with the reflection properties of the product surface. This is needed, for example, when sorting different materials such as stainless steel, steel, tin, zinc, aluminum, brass, gold or other colored parts.

- For metals, plastic parts, thread locking, coating, packaging

- For individual surfaces, direct reflection incl. gloss

- Part detection, sorting tasks, presence checking, color checks

- Detection of smallest objects from 0.8 mm

- Working distance > 300 mm (for reflective surfaces)