High-precision white light interferometers for absolute distance and thickness measurements

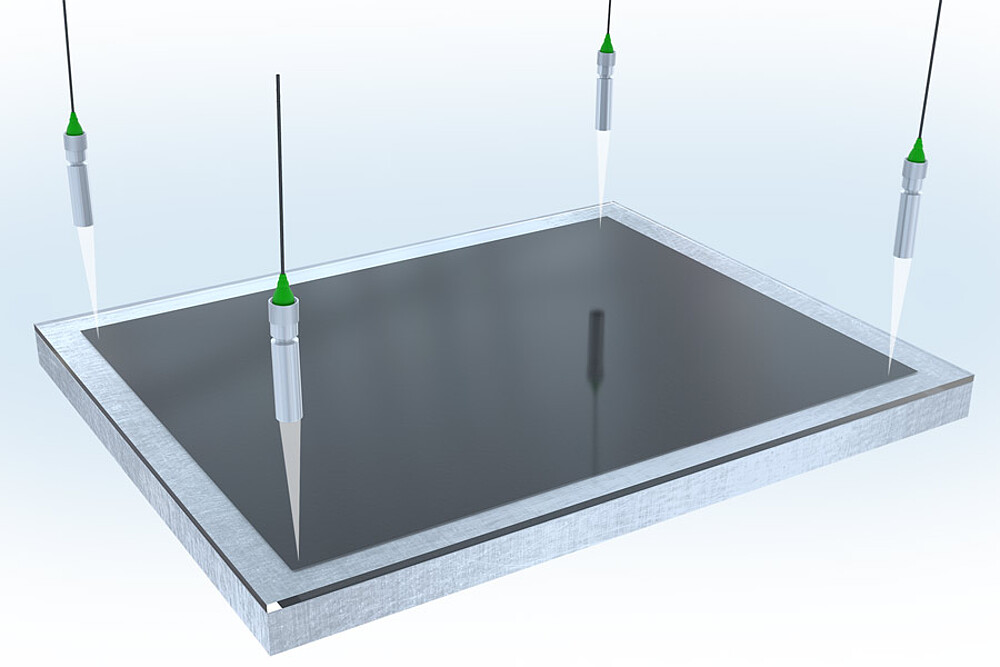

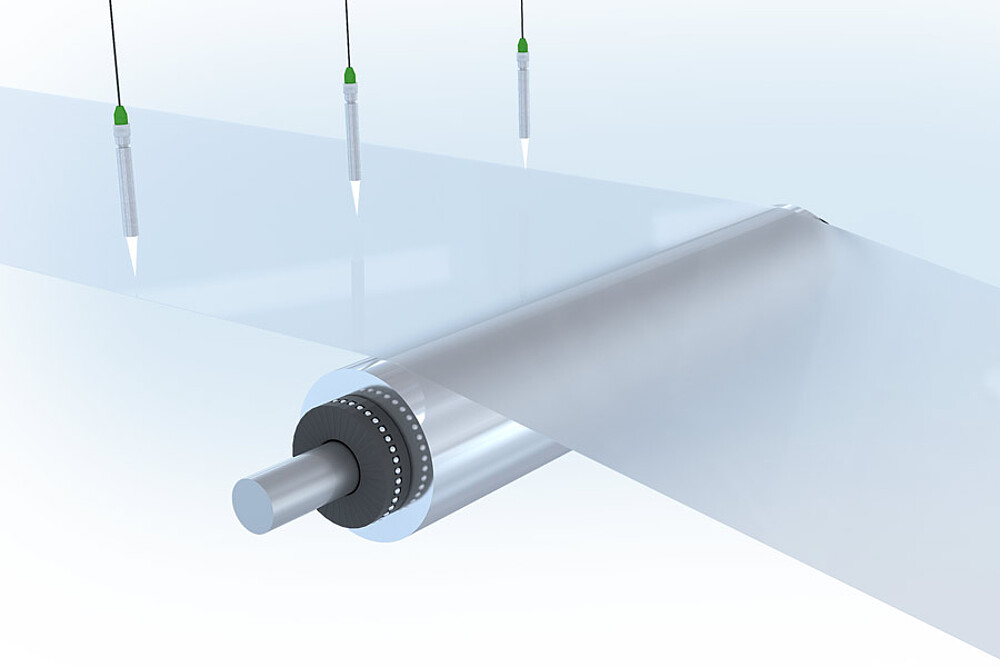

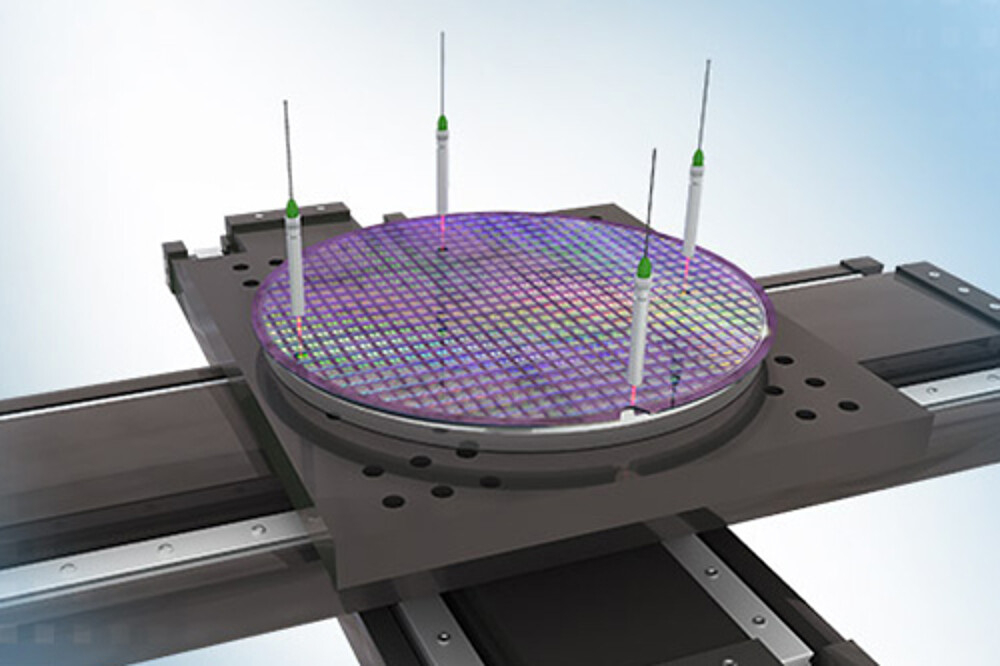

The innovative white light interferometers from Micro-Epsilon set a benchmark in high-precision distance and thickness measurements. The absolute interferometers enable stable measurement results with sub-nanometer resolution offering a comparatively large measuring range and offset distance. The interferometers are used for absolute distance and thickness measurements of transparent objects and wafers.

Convince yourself: measurement accuracy at the highest level for applications in industry and semiconductor machine building.

Models

Significant advantages of the innovative white light interferometers

- Absolute distance measurement with nanometer accuracy

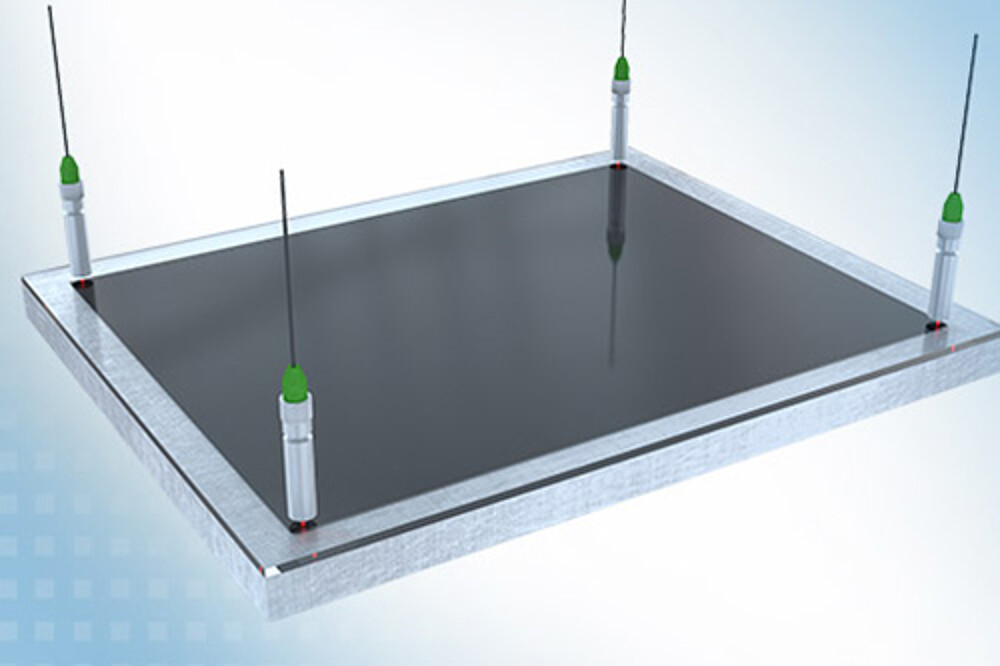

- Reliable thickness measurement: material thicknesses from 1 µm, regardless of the distance of the sensor

- Multi-peak distance measurement and multi-layer thickness measurement

- Best-in-class: resolution < 30 picometers (IMS5600)

- High signal stability due to new evaluation algorithms and active temperature compensation

- Large offset distance

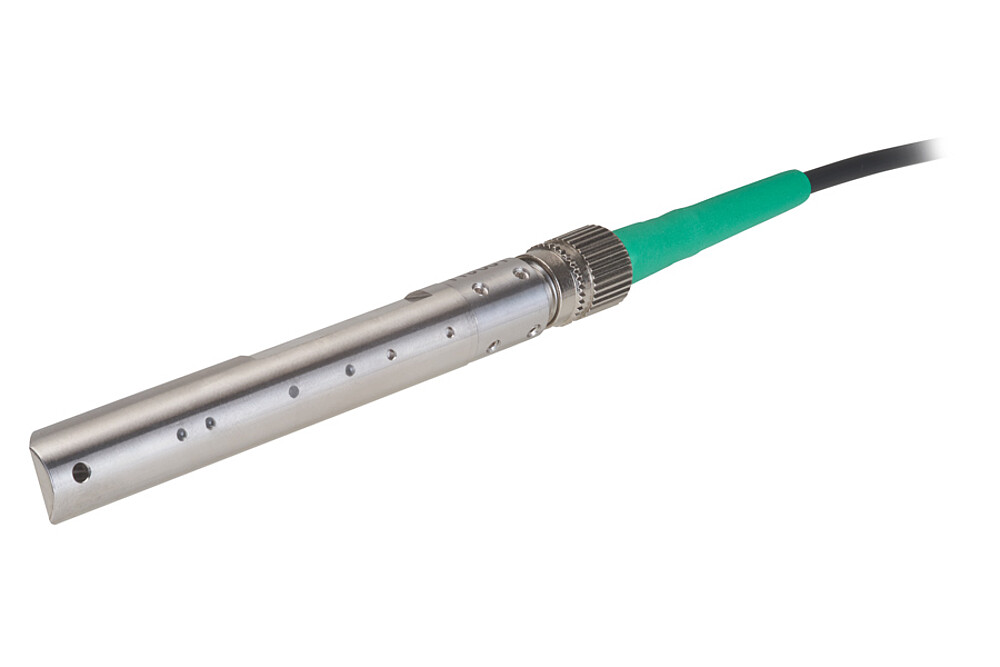

- Industry-optimized sensors with robust metal housing and flexible cables

- Vacuum-compatible sensors and cables

- Simple operation and quick field adjustment on site

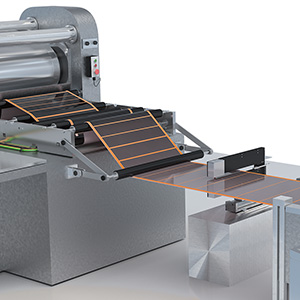

Interferometer for industry and automation

The industrial white light interferometer consists of a robust sensor, a highly flexible sensor cable and a controller in an aluminum housing that can be mounted on a DIN rail. The controller has an active temperature control, which compensates for changes in the ambient temperature and thus achieves an enormous temperature stability. Thanks to its robust design, the interferometer can also be integrated in industrial environments. Cable lengths up to 10 m also allow a spatial separation of sensor and controller. For measurement tasks in clean rooms and in vacuum, vacuum-suitable sensors, cables and cable feed-through accessories are available.

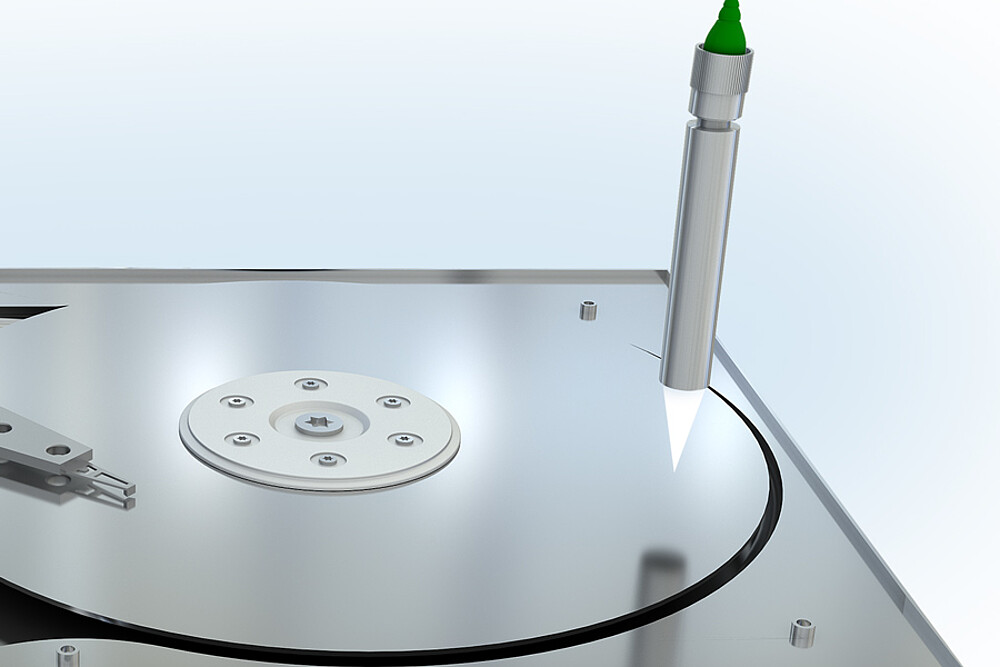

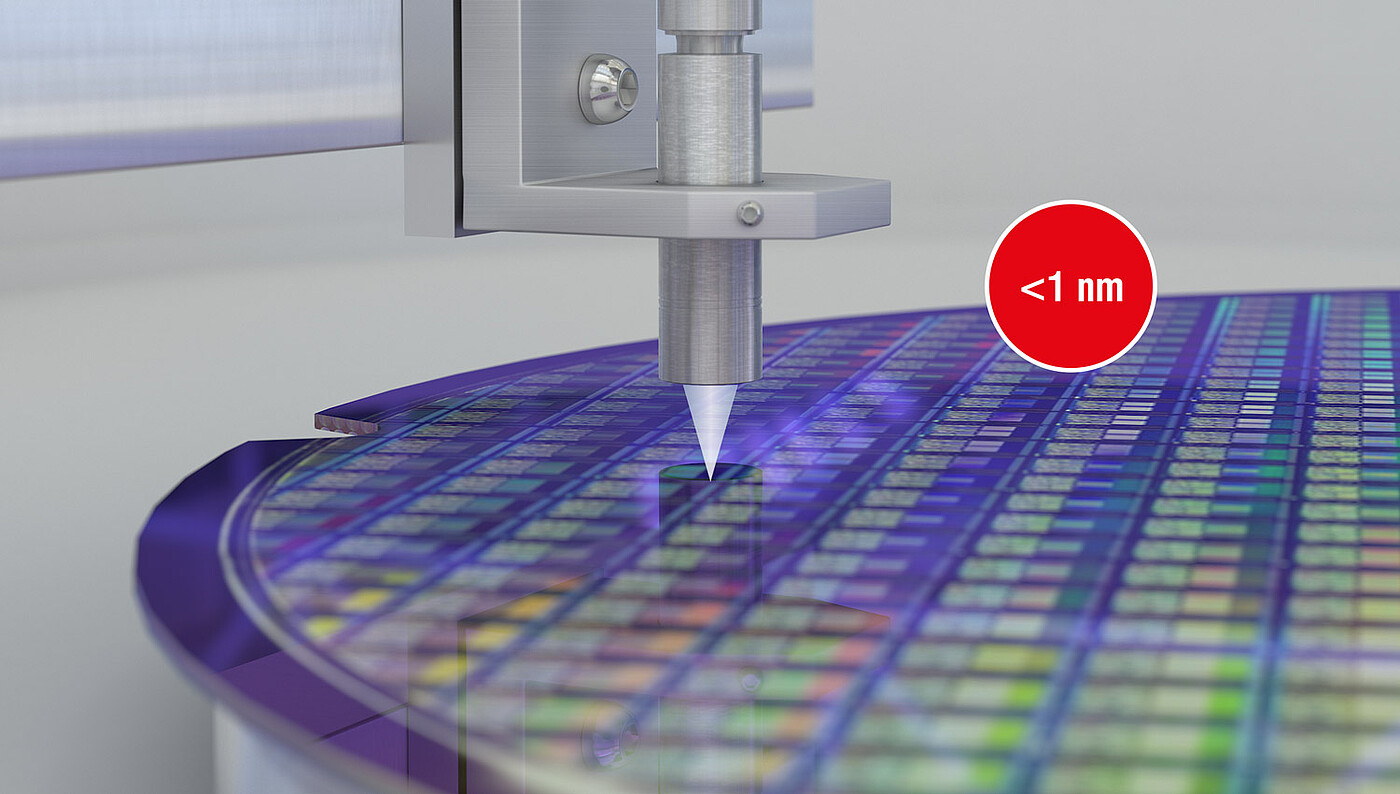

Extreme z resolution and small light spot enable measurements of smallest of details and structures

The interferometer sensors enable a sub-nanometer resolution. In addition, they generate a 10 µm light spot over the entire measuring range. This allows the measurement of small details such as structures on semiconductors and miniaturized electronic components. The light spot is visualized by a pilot laser and facilitates the alignment of the sensor.

New sensor models with different designs

New sensors with different designs and properties are available for the integration in demanding environments. Due to their 90° beam path, both the IMP-DS0.5/90/VAC and the IMP-DS10/90/VAC can also be mounted in low installation spaces. The new IMP-DS1/VAC miniature sensor is one of the smallest optical sensors from Micro-Epsilon. With a diameter of 4 mm and an integrated cable, the sensor can also be used in extremely confined installation spaces. Sensors and cables can be used both in the clean room and in a vacuum.

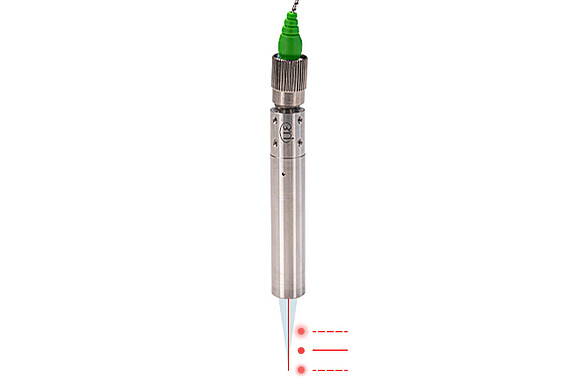

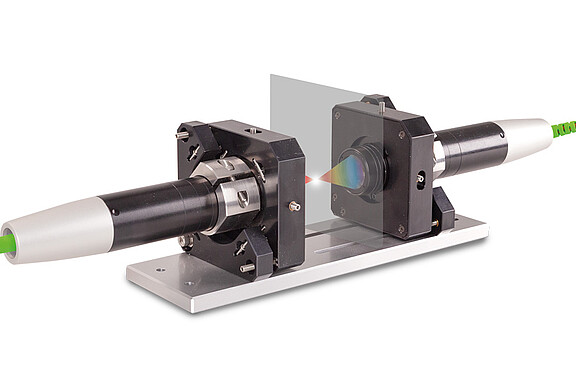

Patented pilot laser for easy sensor positioning

White light interferometers use infrared light in the non-visible range (approx. 840 nm wavelength), which means that the measurement position cannot be seen. To visualize the measuring position, Micro-Epsilon systems are equipped with a pilot laser which projects a light spot onto the measuring position. In addition, the pilot laser uses a patented method to provide feedback on the distance in addition to the measurement position. If the measuring object is at the correct distance and within the measuring range, a constant glow is emitted by the pilot laser. If the measuring object is outside the measuring range, the pilot laser flashes.

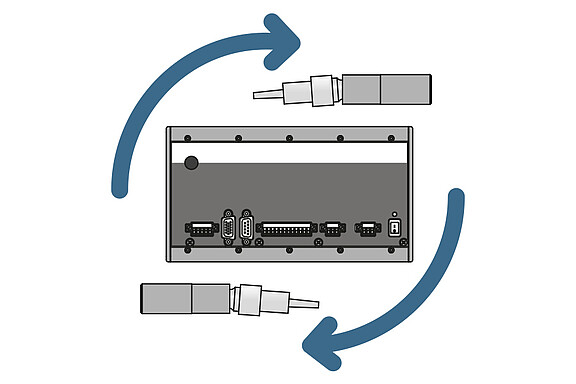

Simple integration on site

- Interchangeability of components enables flexible integration

- Fast and efficient on-site service

- Light source replacement possible by Micro-Epsilon service staff on the production line

- Sensor replacement of the same type (for IMS5400): sensor removal or recalibration at the Micro-Epsilon factory is not necessary

- Length variation and replacement of cables of the same type are possible by the customer: not necessary to send in the system.

Adjustable mounting adapter for sensor alignment

To achieve maximum accuracy, the interferometers must be aligned as perpendicular as possible to the target. With the adjustable mounting adapter, the sensors can be optimally aligned to the measuring object. You can also align the sensor after the installation in the machine. The industrial adapter allows the displacement in the x- and y-axes as well as tilting the sensor to the measuring object.

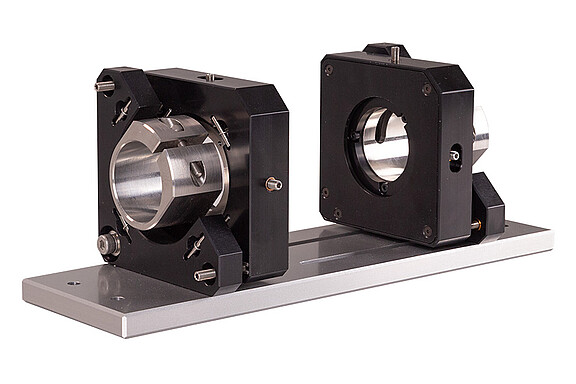

New: Adjustable mounting adapter for two-sided thickness measurement

The JMA-Thickness consists of two adjustable mounting adapters, and supports the alignment of sensors in two-sided thickness measurements. This means that the measuring points can be arranged absolutely congruent on an optical axis, which ensures reliable thickness measurements with highest precision. The JMA-Thickness is ideal for the integration into machines and production plants. The preassembled mounting plates allow quick and easy installation.

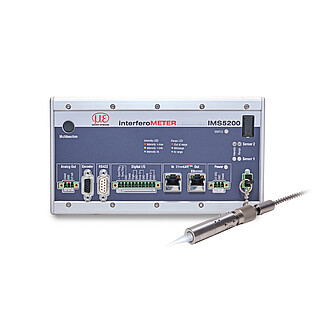

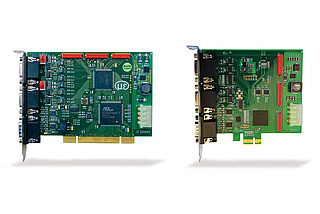

Interface and signal processing units

Modern interfaces for integration into machines and systems

The controller offers integrated interfaces such as Ethernet, EtherCAT and RS422 as well as additional encoder connections, analog outputs, synchronization inputs and digital I/Os. When you use Micro-Epsilon's interface modules, PROFINET and EthernetIP are available. This allows the interferometer to be integrated into all control systems and production programs.