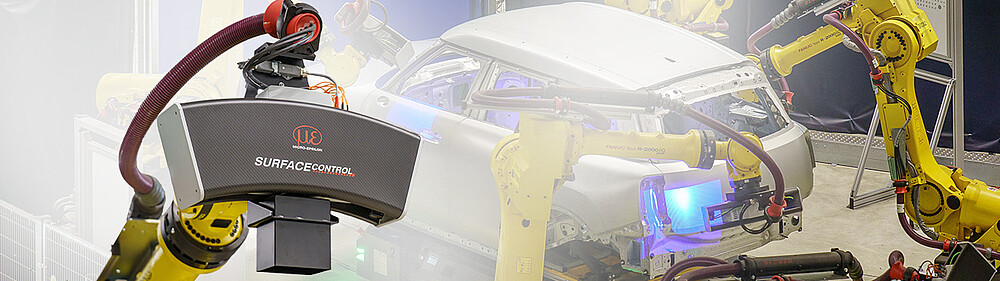

Defect detection on bodyshells

In modern automotive production, quality assurance is a central component of the manufacturing process. The early detection of typical sources of defects such as dents or cracks is particularly important in the shell construction phase.

The surfaceCONTROL Automotive measuring system is used for fully automatic defect detection on body shells. It consists of a sensor, robot, computer and software and interface package and impresses with its high coverage even on curved surfaces such as door handles and edges.

The defects on the bodyshells are precisely detected and localized. Thanks to the unique 3D reconstruction, each defect is assigned detailed 3D characteristics such as height, depth and volume. Depending on the user's specifications, errors can be classified individually. This enables targeted reworking at the relevant points.