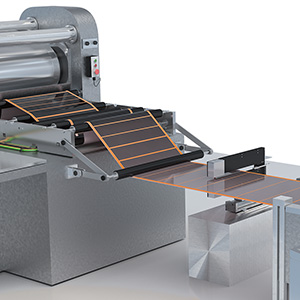

The optoNCDT 1900 laser triangulation sensors are used for automated displacement, distance and position measurements in industrial processes. They deliver high accuracy results in automotive manufacturing, 3D printing, coordinate measuring machines, injection molding, packaging and CNC machines, among others, as well as in the battery industry, smartphone production, robotics applications and wood processing.

For flexible connection to control systems, the optoNCDT 1900 sensors have integrated EtherCAT, EtherNet/IP and PROFINET interfaces. With its integrated Industrial Ethernet interfaces, the sensor offers advantages particularly in high speed processes and for networking of several devices and machines.

A special feature is the high signal stability during fast measurements. Two-stage measurement averaging enables a smooth signal at steps and edges and prevents signal overshoots. This allows a precise signal course for fast measurements of moving parts.

Advanced Surface Compensation ensures stable results with changing surfaces. It adjusts the exposure time to the conditions imposed by the target during rapid surface changes. This results in smooth signals even with fast matt-to-gloss or light-to-dark transitions.

The optoNCDT 1900 is mounted using a patented mounting concept. Fitting sleeves ensure that the sensor is automatically aligned in the correct position. This generates measurements with the highest precision, but also the possibility of replacing the sensor quickly. No external control unit is required to operate the sensor, as the controller is integrated into the compact sensor housing. Due to its small dimensions, the laser sensor can be mounted even when space is limited.