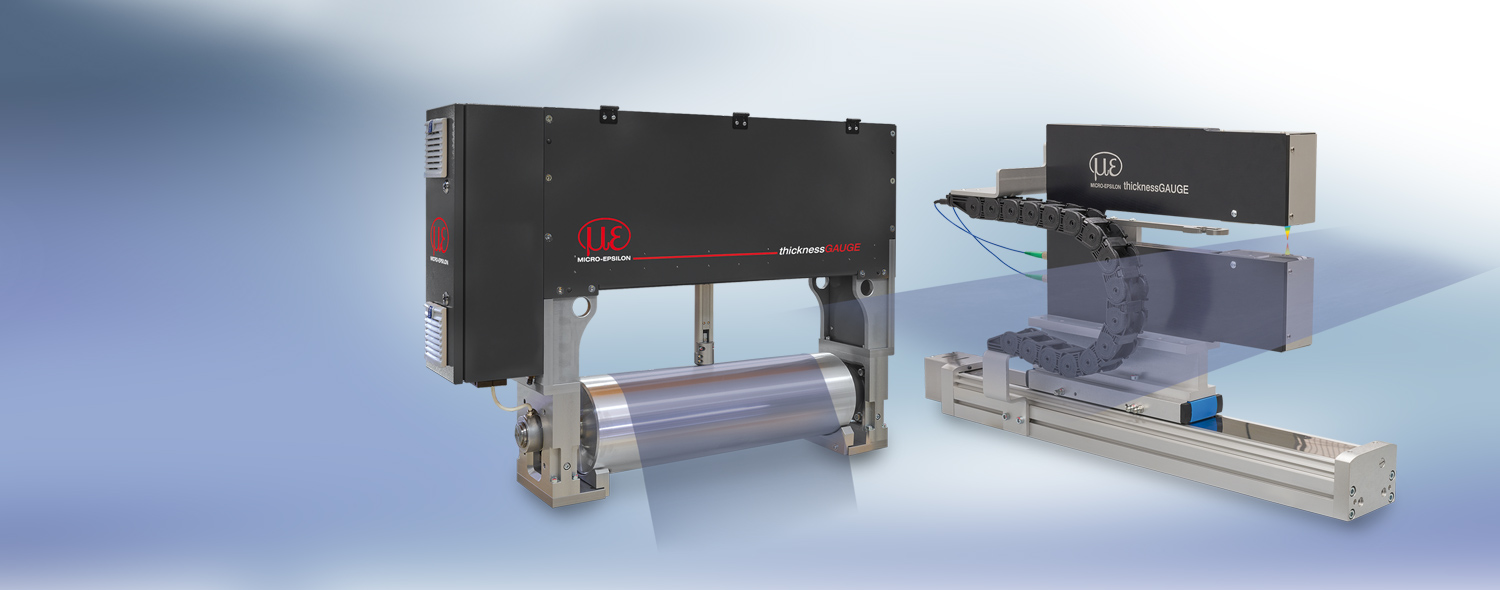

Sensor system for precise thickness measurement of strip and plate materials

thicknessGAUGE sensor systems are used for precise thickness measurements of strip materials, plates and sheets up to 50 mm. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces based on an unmatched price/performance ratio.

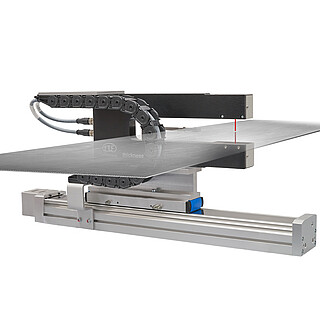

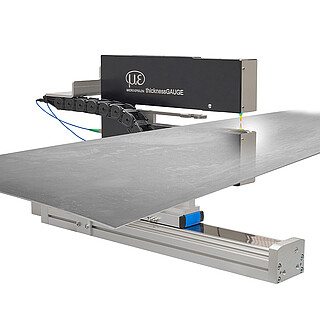

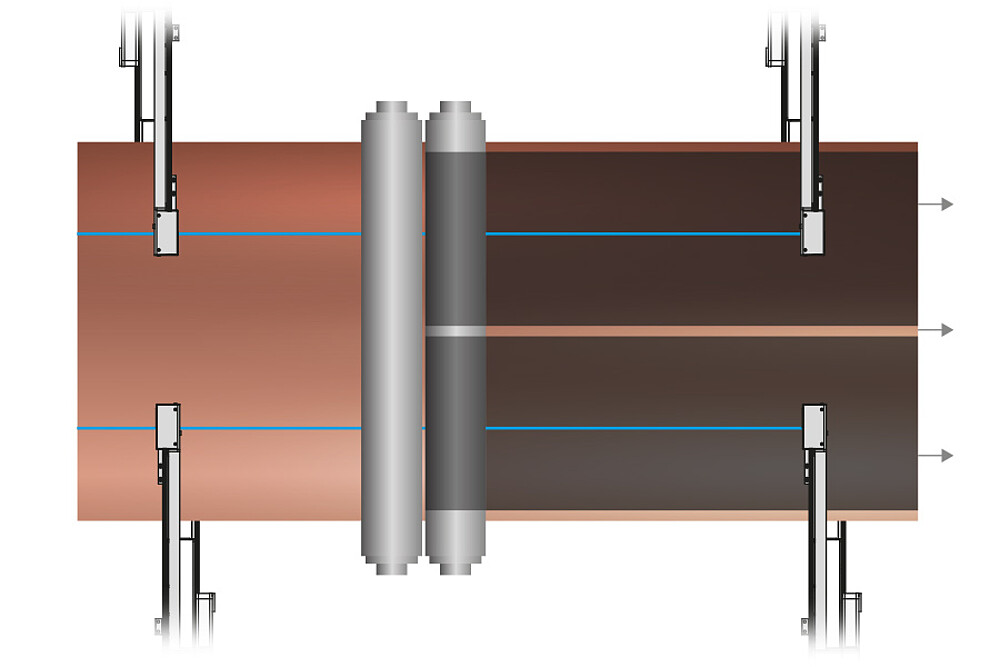

This fully assembled system comprises a stable frame on which two optical distance sensors are fixed, which detect the thickness of the measuring object according to the difference principle. The sensors are perfectly aligned to each other in terms of their mounting condition. Furthermore, thickness calibration at the factory enables high precision thickness measurements.

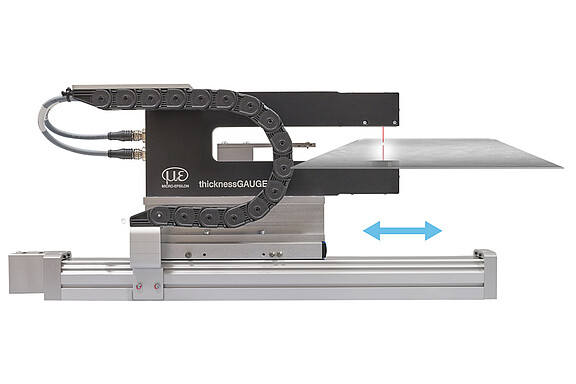

A linear axis moves the sensor system from the parking position to the measuring position. A measurement standard for fully automatic calibration is in the parking position.

Models

Characteristics

- Compact complete solution for precise inline thickness measurements

- For many types of surfaces and materials due to different sensor technologies

- Traversing sensors on linear axis

- Fully automatic calibration

- 24 V supply for the entire system

- Integrated software

- Ideal price/performance ratio

Thickness measurement with high precision

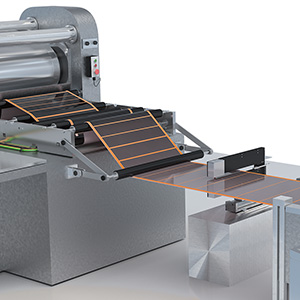

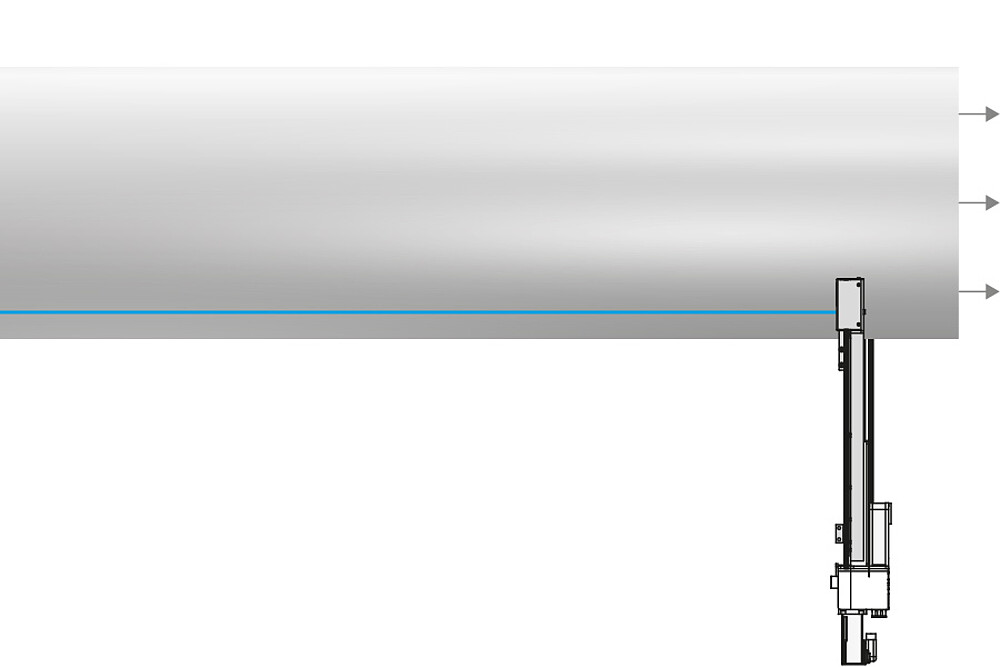

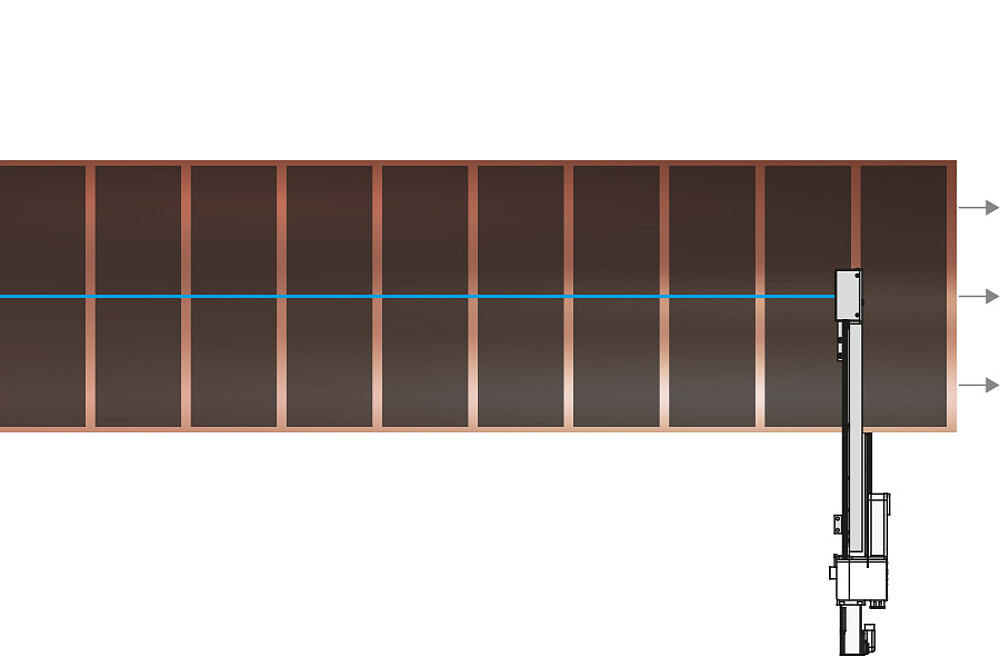

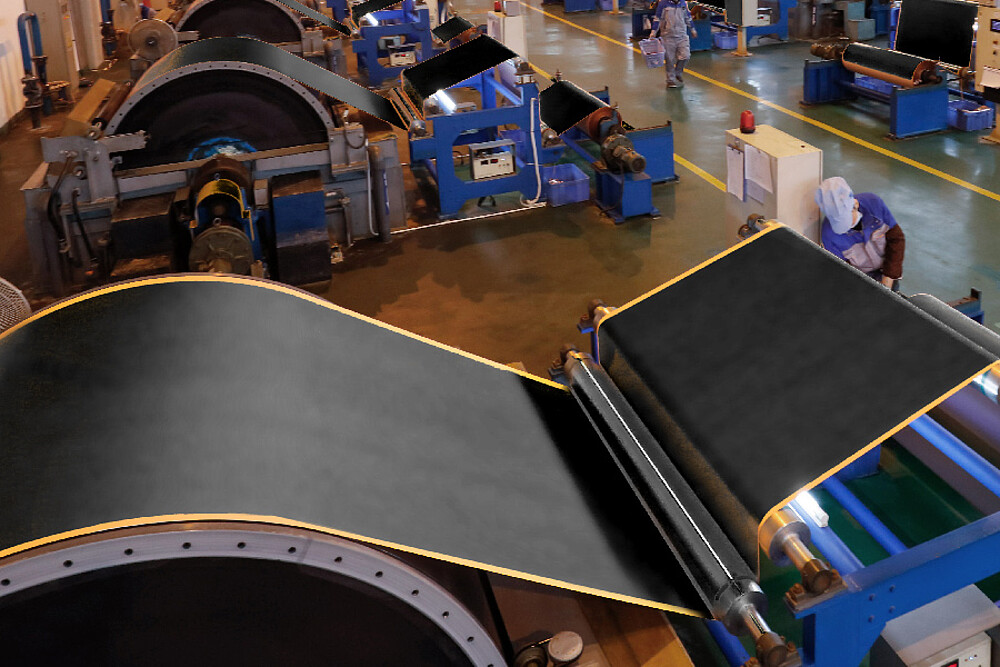

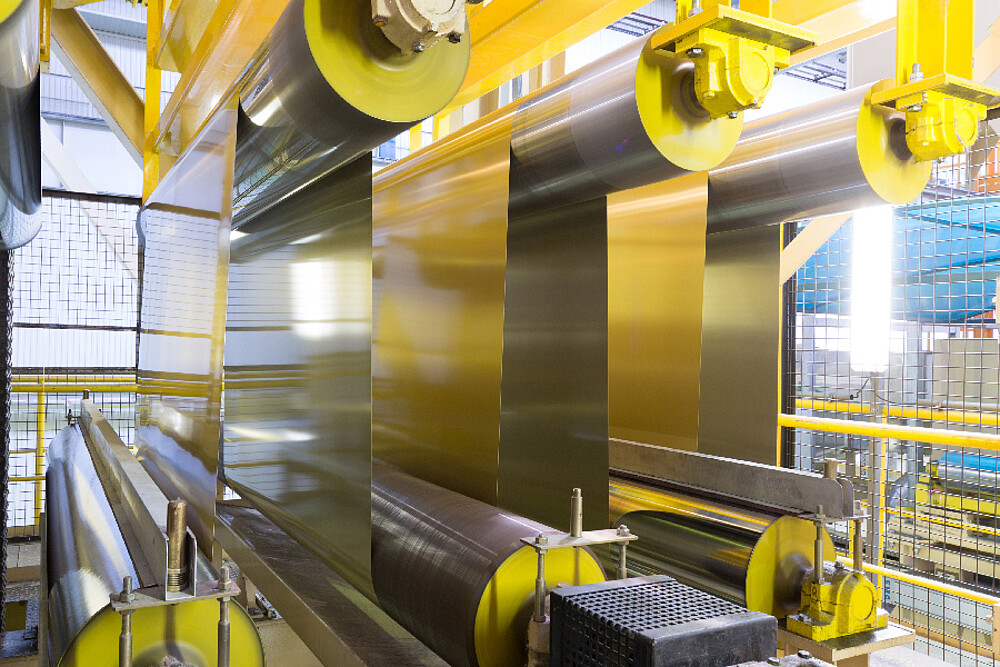

thicknessGAUGE sensor systems are used in industrial environments for precise thickness measurements of strip and plate materials. A linear unit with electromechanical drive enables thickness measurements in traversing mode. Alternatively, fixed track measurements are possible for center-line measurements (center thickness) or for thickness measurements on the edges.

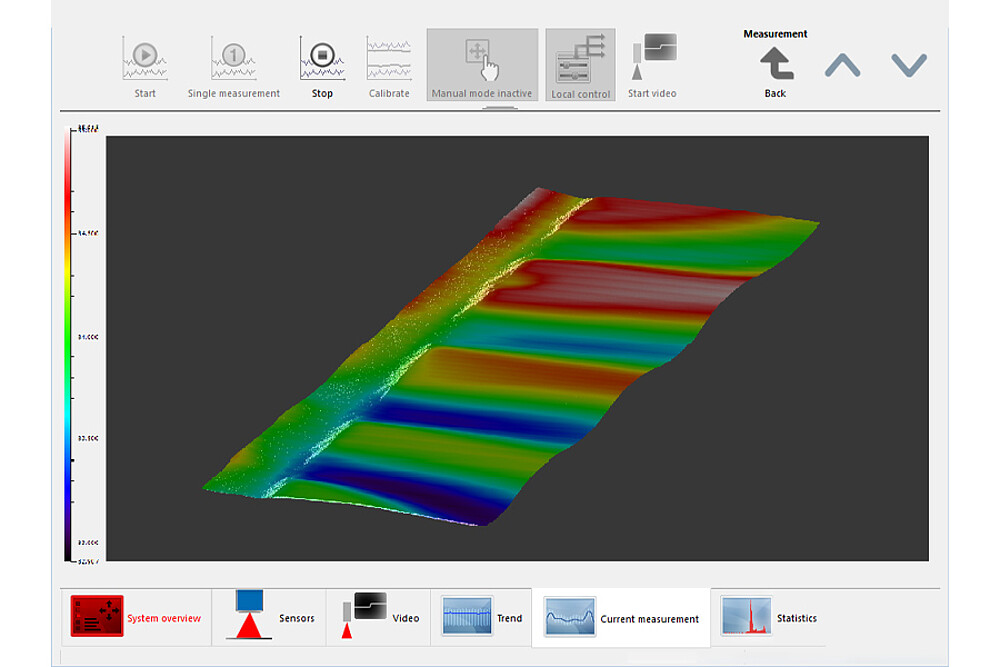

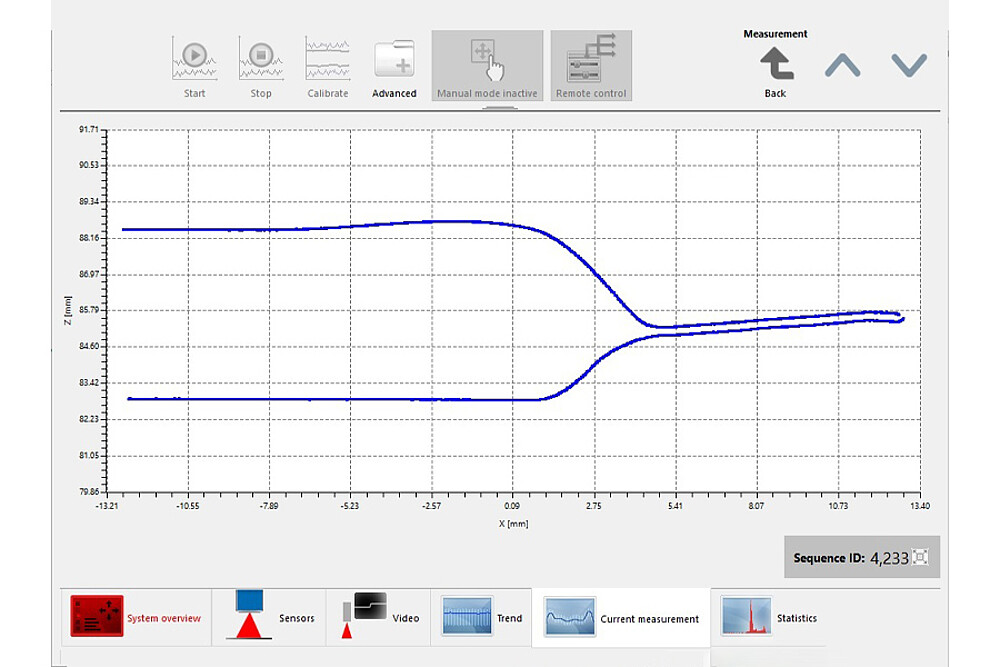

Precise profile and 3D inline measurements

The thicknessGAUGE 3D systems are used for precise inline measurement of geometric shapes such as film curvature, the edge of coating applications or weld seams on pouch cells. The sensor systems are equipped with two laser scanners. These detect the profile data along a linear movement, merge it into an overall profile and thus enable 2D or 3D evaluation. Variables such as step height, curvature or radius can be freely programmed, allowing complex measurement tasks to be solved directly in the inline process.

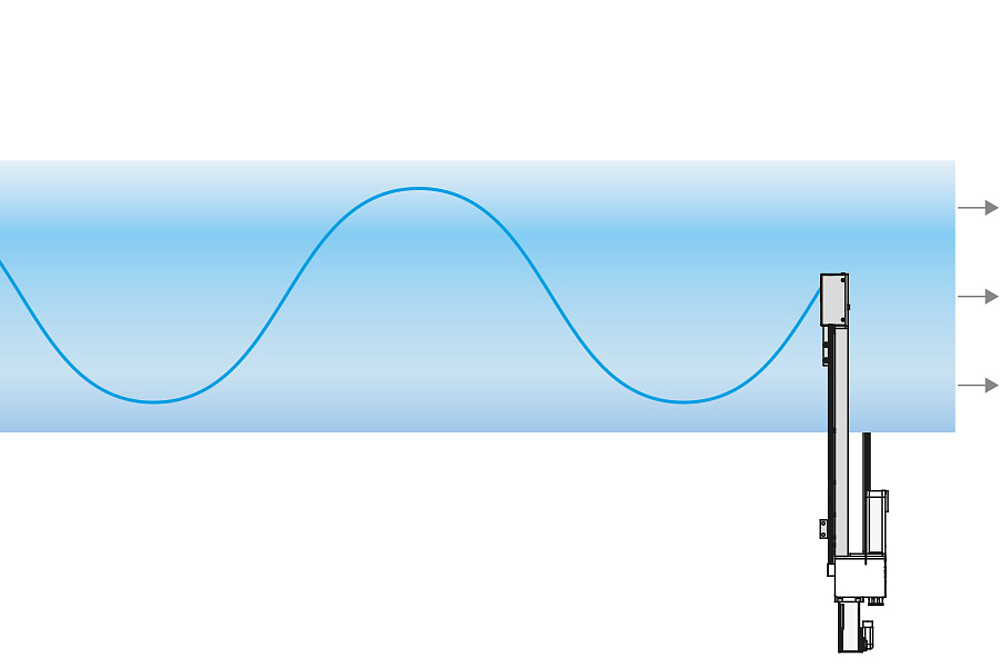

Automatic calibration & temperature compensation

thicknessGAUGE systems are equipped with in-situ calibration in order to compensate, e.g., for the effects of fluctuating temperatures. The calibration cycles are individually adjustable. In addition to temperature compensation, in-situ calibration enables proper functioning of the system to be verified cyclically and at any time.

100 % quality control during production

The thicknessGAUGE sensor systems are used in strip processes and plate production in order to measure the thickness continuously. Based on high precision and equipped with intelligent sensor technology, these sensor systems are used in various industries.