Clamping stroke sensors reliably detect the displacement of rotating shafts

Micro-Epsilon's clamping stroke sensors ensure the perfect fit of the tool, optimize machining accuracy and protect both man and machine from possible damage.

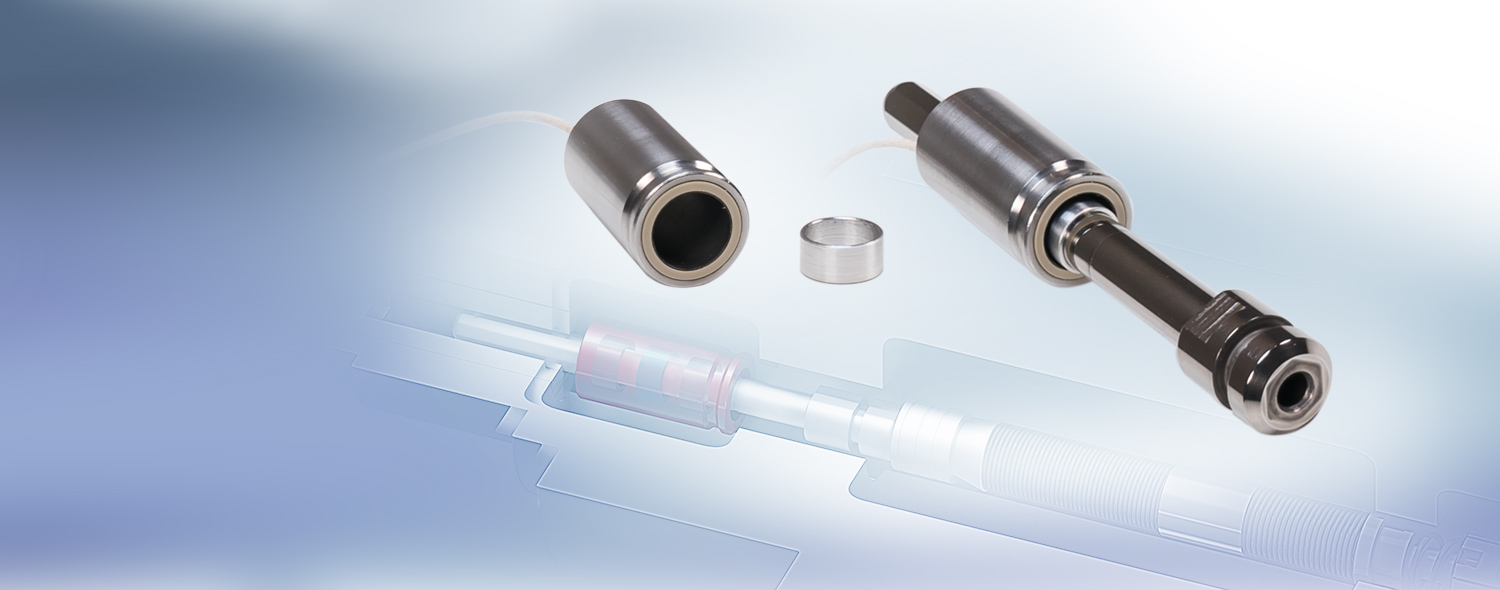

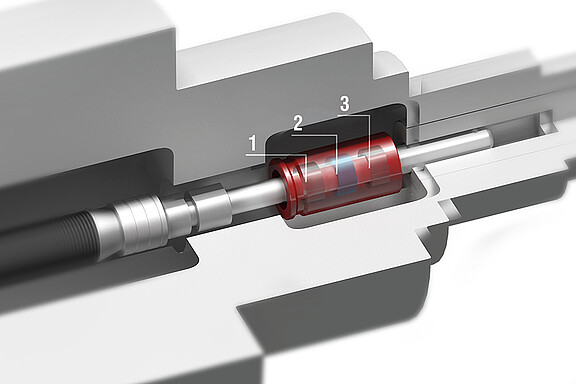

The LVP-25-Z20 and LDR-14-Z20 sensors are the ideal solution for monitoring the tool position in high-performance spindles during the changing process. The innovative inductive measuring principle of these robust sensors ensures maximum reliability when monitoring the stroke movement of the drawbar. Consequently, continuous monitoring is possible without the switching point having to be set mechanically.

Your advantages at a glance

- Compact design - ideal for confined installation spaces

- Wear-free measuring principle - no wear, longer service life

- High resolution & repeatability - for maximum process reliability

- Easy integration - can be integrated directly into the release device

- Various output signals - analog or digital interfaces

- Ideal for series integration - high quantities with the best price-performance ratio

Innovative sensor technology for the highest demands

The LVP-25-Z20 and LDR-14-Z20 sensors measure the clamping stroke of the drawbar directly and provide a continuous signal for precise monitoring. While conventional systems rely on switching rings that require complex adjustment, Micro-Epsilon's clamping stroke sensors offer an easy solution without mechanical adjustment.

Flexible use - even under harsh conditions

Their robust design makes these sensors ideally suited for demanding industrial environments where high precision is required but conventional sensors reach their limits.

System configurations as required

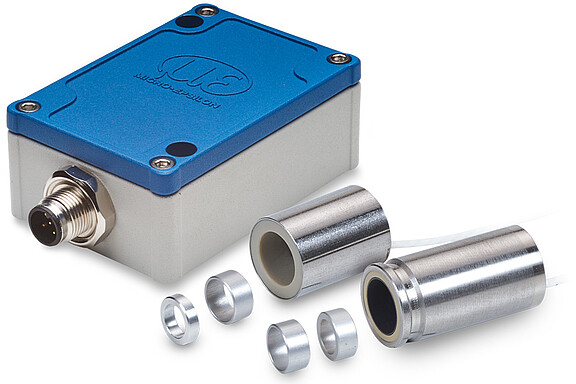

The LVP-25-Z20 and LDR-14-Z20 sensors can be operated with various controllers that offer analog or digital interfaces for connection to the machine control system. Modifications of the electronics, measuring ranges, sensor design and temperature range can be implemented individually for series applications. Get in touch with us!

- Data sheet clamping stroke sensor (pdf, 632.85 KB)

- Data sheet induSENSOR MSC7401 / MSC7802 (pdf, 1.29 MB)

- Industry brochure Machine Tools (pdf, 1.72 MB)

- Setup Guide induSENSOR LVP-25-Z20 LDR-14-Z20 (pdf, 438.26 KB)

- CAD file 3D-model "induSENSOR LVP-25" clamping position sensor, STEP (zip, 300.35 KB)

- CAD file 3D-model "Controller MSC7xxx", STEP (zip, 4.21 MB)