- Micro-Epsilon

- Distance Sensors

- Inductive sensors (eddy current)

- Specific sensors

Custom eddy current sensors

Modifying the standard eddyNCDT sensors is sometimes necessary particularly for small and large series. Therefore, we modify the measuring systems according to your specific requirements, e.g., changes to the cable, sensor material and design, and to the controller. In particular, sensors with integrated electronics in a miniature housing or special sensor designs are often requested by systems integrators.

Available options

- Modified offset distance and measuring range

- Housing and mounting options for sensor and controller

- Pressure-resistant sensors up to 2,000 bar

- Sensors with integrated or external controller, miniature design

- Various materials for coil, housing and circuit boards

- Individual cable lengths, specific target calibrations

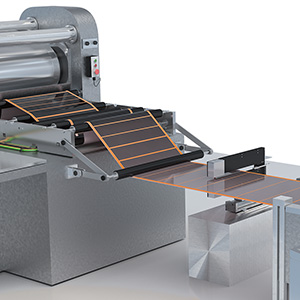

Customized inductive displacement sensors with Embedded Coil Technology

For particularly demanding OEM projects, we recommend the Embedded Coil Technology (ECT). Due to the miniature sensor design in inorganic material, almost all degrees of freedom for the outer shape are given. If required, the entire evaluation electronics can be integrated into the sensor. This allows ECT sensors to be adapted to special installation situations. ECT sensors are suitable for the harshest operating conditions and have proven successful, e.g., in the alignment of mirror segments on telescopes, semiconductor production in ultra-high vacuum and mill gap measurement of refiners in the paper industry.

Features:

- Highest resolution

- High long term stability

- Reproducible temperature course

- Extremly robust mechanics

- Ideal for high temperatures up to 350°C

Application in vacuums

The eddyNCDT series delivers high-precision measurement results even in airless rooms. The eddy/fB0/fB0/triax vacuum feedthrough also enables eddyNCDT products to be used in vacuum applications.

Details:

- Very good leakage rate max. <10ˉ⁸ mbar l/s

- 10,000 mating cycles