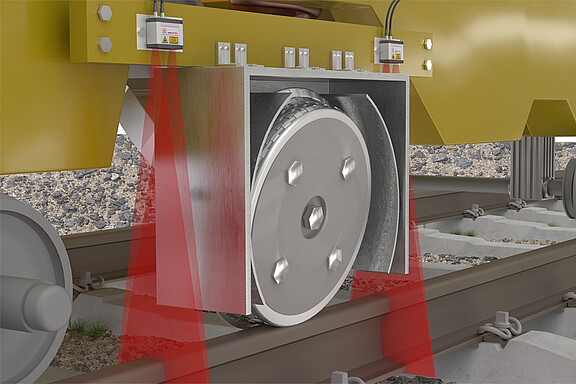

Inspection of the rail profile during grinding and milling

Rail milling trains are used for repair work on tracks. In order to detect the rail profile before and after the milling head, scanCONTROL laser profile sensors are used immediately before and after the grinding wheel. The target and actual status are thus recorded automatically and transferred to the central control unit in the milling train. The scanCONTROL laser scanners have an integrated controller, whereby the profile evaluation takes place directly in the sensor.

Thanks to the high resolution and the high profile frequency, the scanners can be used during ongoing driving operations.