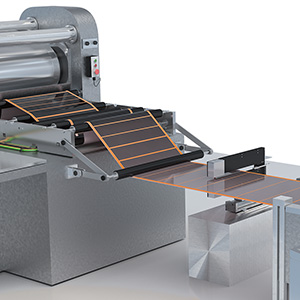

Edge detection of fabric strips in the cutting machine

If the position of the material web is not recognized or is recognized incorrectly, this can result in waste from faulty cutting and machine malfunctions due to missing controller signals. Therefore, the optoCONTROL CLS-K-31 fiber optic sensor from Micro-Epsilon is used for position detection.

The sensor reliably detects the beginning of the roll. It is mounted directly on one of the cutting blades and recognizes from a distance of around 140 mm when the fabric is in the cutting position. A switching output (PNP) transmits a signal level directly to the controller and the cutting process begins. In this way, the cutting elements can be positioned exactly to 0.5 to 2 mm depending on the material. After each cut, the fabric position is recalculated. The measuring process is carried out at feed speeds of 20 m/min.

The optoCONTROL CLS-K-31 measuring system from Micro-Epsilon provides highly reliable and reproducible measurement results, which ultimately optimizes cutting accuracy, while reducing waste and process disruptions. The CLS-K-31 is even virtually insensitive to scratches and contamination on the shiny metallic surface of the roller.