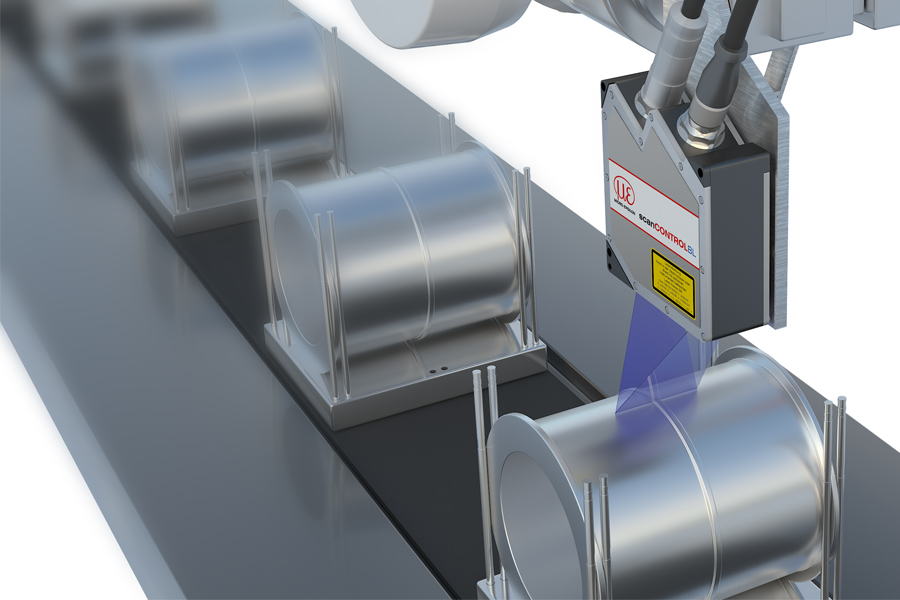

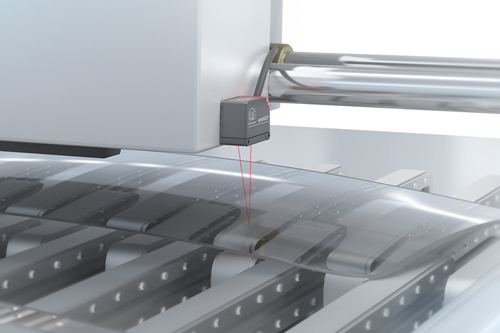

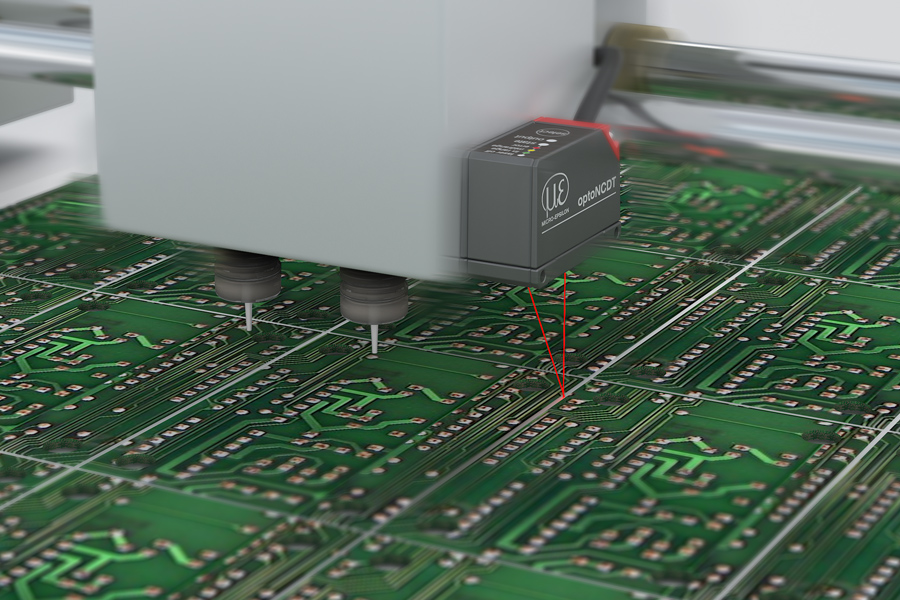

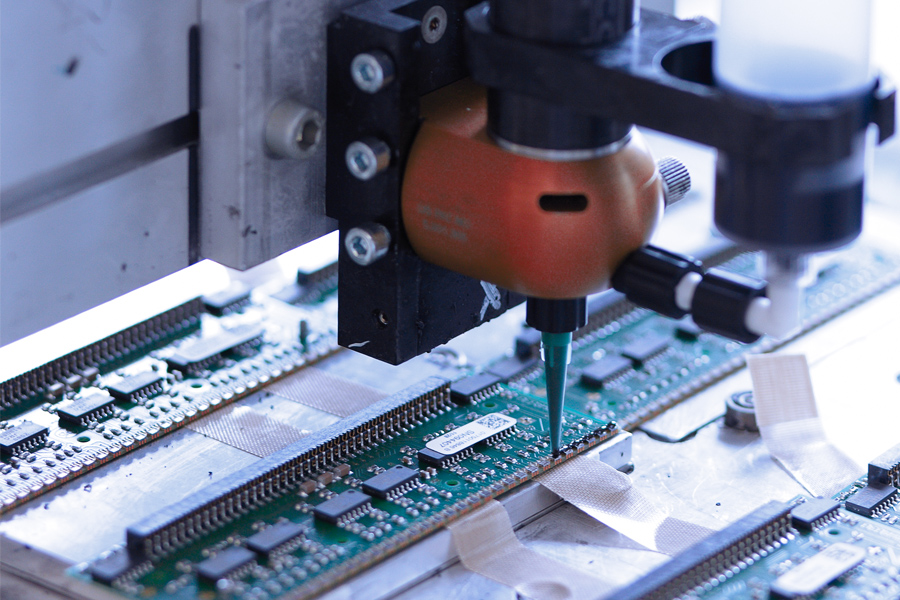

Monitoring the positioning and component dimension

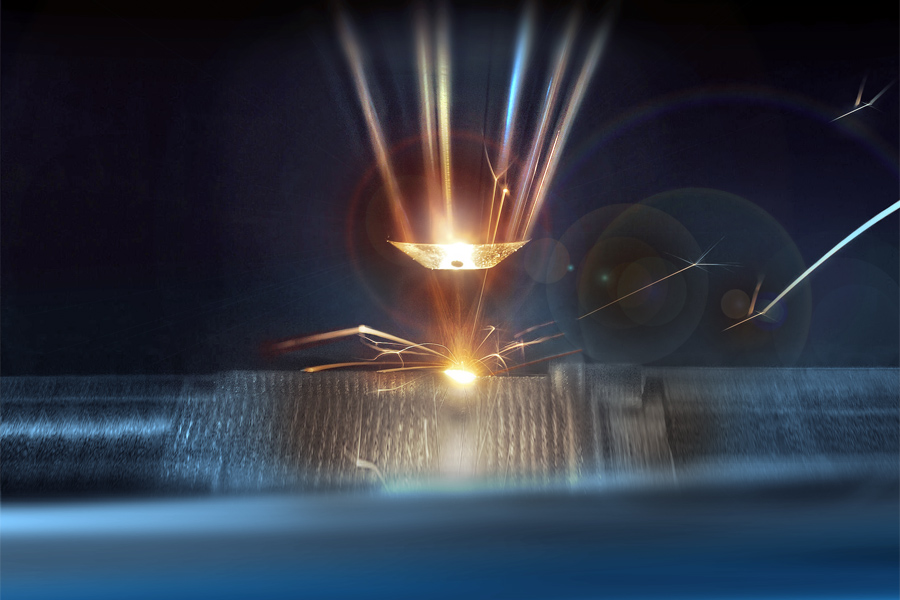

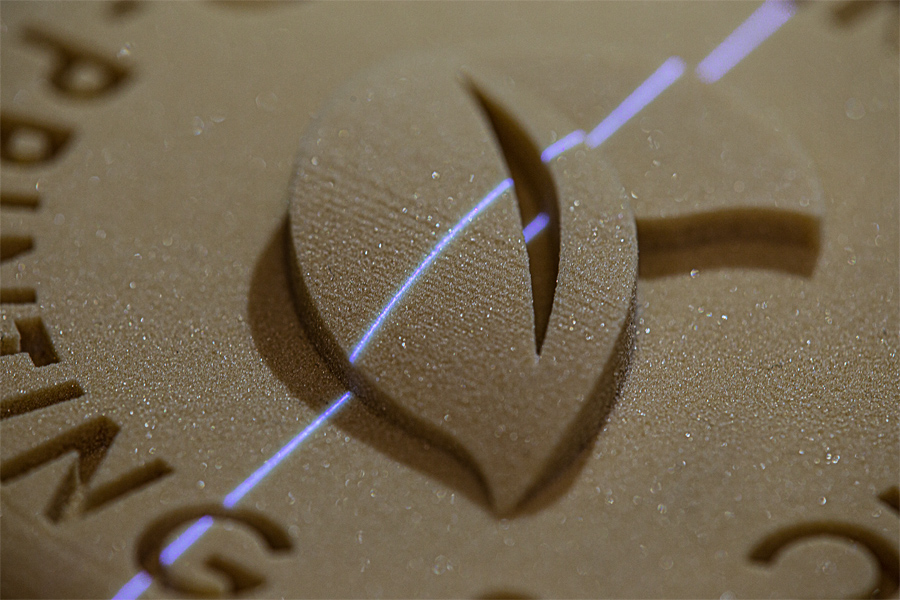

In additive manufacturing, different parameters have to be monitored. Particularly where high manufacturing quality is required, sensors from Micro-Epsilon monitor positioning, powder application and component dimensioning tasks. Laser sensors, laser scanners, inductive displacement sensors based on eddy currents and capacitive displacement sensors are just some of the sensors used.