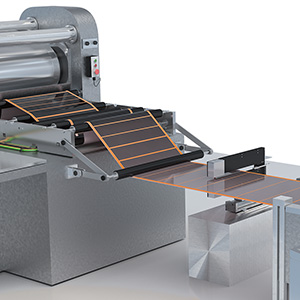

Monitoring the deflection of wire saws

Wire saws are used to cut ingots in only one step. Since the wire is subject to strong wear, the wire bed is monitored at several points using non-contact eddy current sensors. These not only detect the wire height on the guide roller but also the wire sag, thus enabling fast and highly precise detection of wire wear. This robust measuring principle is insensitive to dust and dirt and enables high-resolution measurement results.