- Distance Sensors

- Inductive sensors (eddy current)

- Configurator

- eddyNCDT 3001

![eddyNCDT 3001 Inductive sensors (eddy current)]() Compact eddy current sensors with integrated controller

Compact eddy current sensors with integrated controller - eddyNCDT 3005

![eddyNCDT 3005 Inductive sensors (eddy current)]() Miniature sensor system for integration into machines and systems

Miniature sensor system for integration into machines and systems - eddyNCDT 3060/3070

![eddyNCDT 3060/3070 Inductive sensors (eddy current)]() High-performance sensor system for industrial applications

High-performance sensor system for industrial applications - eddyNCDT 3300

![eddyNCDT 3300 Inductive sensors (eddy current)]() Ideal for high speed measurement tasks

Ideal for high speed measurement tasks - SGS 4701 Spindle Growth System

![SGS 4701 Spindle Growth System Inductive sensors (eddy current)]()

- Specific sensors

![Specific sensors Inductive sensors (eddy current)]()

- Capacitive sensors

- Sensor configurator

- capaNCDT 6110

![capaNCDT 6110 Capacitive sensors]() Ideal for industrial applications

Ideal for industrial applications - capaNCDT 61x0/IP

![capaNCDT 61x0/IP Capacitive sensors]() Robust design for industrial applications

Robust design for industrial applications - capaNCDT 61x4

![capaNCDT 61x4 Capacitive sensors]() Active measuring system for long cables

Active measuring system for long cables - capaNCDT 6200

![capaNCDT 6200 Capacitive sensors]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT 6228

![capaNCDT 6228 Capacitive sensors]() Ideal for high-temperature applications

Ideal for high-temperature applications - capaNCDT 6500

![capaNCDT 6500 Capacitive sensors]() Ideal for high-precision multi-channel measurements

Ideal for high-precision multi-channel measurements - capaNCDT sensors

![capaNCDT sensors Capacitive sensors]()

- Customer-specific sensors

![Customer-specific sensors Capacitive sensors]()

- combiSENSOR

![combiSENSOR Capacitive sensors]()

- capaNCDT DTV

![capaNCDT DTV Capacitive sensors]()

- capaNCDT MD6-22

![capaNCDT MD6-22 Capacitive sensors]()

- capaNCDT TFG6220

![capaNCDT TFG6220 Capacitive sensors]() Thickness measurement of electrically conductive films

Thickness measurement of electrically conductive films

- Laser sensors

- Configurator

- optoNCDT 1220

![optoNCDT 1220 Laser sensors]() Optimized for OEM and series use

Optimized for OEM and series use - optoNCDT 1320

![optoNCDT 1320 Laser sensors]() Compact design for precise measurements

Compact design for precise measurements - optoNCDT 1420

![optoNCDT 1420 Laser sensors]() Smart laser sensor for precise measurements

Smart laser sensor for precise measurements - optoNCDT 1900

![optoNCDT 1900 Laser sensors]() Innovative laser sensor for Advanced Automation

Innovative laser sensor for Advanced Automation - optoNCDT 2300

![optoNCDT 2300 Laser sensors]() Highly dynamic laser sensor for precise measurements

Highly dynamic laser sensor for precise measurements - optoNCDT 5500

![optoNCDT 5500 Laser sensors]() High-performance laser sensor for high-end applications

High-performance laser sensor for high-end applications - Blue Laser Sensors (BL)

![Blue Laser Sensors (BL) Laser sensors]() Blue Laser sensor for metals and organic materials

Blue Laser sensor for metals and organic materials - Laser Line Sensors (LL)

![Laser Line Sensors (LL) Laser sensors]() Ideal for shiny metallic and textured surfaces

Ideal for shiny metallic and textured surfaces - Long-range laser sensors

![Long-range laser sensors Laser sensors]() Ideal for large measurement distances

Ideal for large measurement distances - Customer-specific sensors

![Customer-specific sensors Laser sensors]()

- thicknessSENSOR

![thicknessSENSOR Laser sensors]()

- Confocal sensors

- Sensor configurator

- Confocal chromatic sensors

![Confocal chromatic sensors Confocal sensors]()

- confocalDT IFD2411

![confocalDT IFD2411 Confocal sensors]() Compact controller for series applications

Compact controller for series applications - confocalDT IFD2410/2415

![confocalDT IFD2410/2415 Confocal sensors]() Compact sensors with integrated controller

Compact sensors with integrated controller - confocalDT IFC2411

![confocalDT IFC2411 Confocal sensors]() Compact single-channel controller for industrial series applications

Compact single-channel controller for industrial series applications - confocalDT IFC2416

![confocalDT IFC2416 Confocal sensors]() Compact single-channel controller for industrial series applications

Compact single-channel controller for industrial series applications - confocalDT IFC2421/22

![confocalDT IFC2421/22 Confocal sensors]() Single or dual-channel controller for industrial applications

Single or dual-channel controller for industrial applications - confocalDT IFC2465/66

![confocalDT IFC2465/66 Confocal sensors]() One / two-channel controller for fast & precise measurements

One / two-channel controller for fast & precise measurements - Accessories

- Interferometers (absolute)

- interferoMETER 5200-TH

![interferoMETER 5200-TH Interferometers (absolute)]() Reliable inline measurement of thin layers

Reliable inline measurement of thin layers - interferoMETER 5400-DS

![interferoMETER 5400-DS Interferometers (absolute)]() Absolute distance measurement with nanometer accuracy

Absolute distance measurement with nanometer accuracy - interferoMETER 5400-TH

![interferoMETER 5400-TH Interferometers (absolute)]() Stable thickness measurement with submicrometer accuracy

Stable thickness measurement with submicrometer accuracy - interferoMETER 5600-DS

![interferoMETER 5600-DS Interferometers (absolute)]() Absolute distance measurement with subnanometer accuracy

Absolute distance measurement with subnanometer accuracy - interferoMETER 5420-TH

![interferoMETER 5420-TH Interferometers (absolute)]() High-precision thickness measurement of SI wafers

High-precision thickness measurement of SI wafers

- interferoMETER 5200-TH

- Laser distance sensors

- optoNCDT ILR1171

![optoNCDT ILR1171 Laser distance sensors]() High speed sensors also for outdoor applications

High speed sensors also for outdoor applications - optoNCDT ILR2250

![optoNCDT ILR2250 Laser distance sensors]() High-performance laser distance sensors

High-performance laser distance sensors - optoNCDT ILR3800

![optoNCDT ILR3800 Laser distance sensors]() High-performance laser distance sensor for industrial applications

High-performance laser distance sensor for industrial applications - optoNCDT ILR104x

![optoNCDT ILR104x Laser distance sensors]() Compact and reliable laser distance sensor

Compact and reliable laser distance sensor

- optoNCDT ILR1171

- Inductive sensors (LVDT)

- induSENSOR DTD gauge

![induSENSOR DTD gauge Inductive sensors (LVDT)]() Push-button with compact cable controller

Push-button with compact cable controller - induSENSOR DTA gauge

![induSENSOR DTA gauge Inductive sensors (LVDT)]() LVDT gauges

LVDT gauges - induSENSOR DTA sensors

![induSENSOR DTA sensors Inductive sensors (LVDT)]() LVDT displacement sensors

LVDT displacement sensors - induSENSOR LDR

![induSENSOR LDR Inductive sensors (LVDT)]() Linear displacement sensors

Linear displacement sensors - Clamping stroke sensor

![Clamping stroke sensor Inductive sensors (LVDT)]() Sensors for monitoring the clamping position

Sensors for monitoring the clamping position - MSC7x0x controller

![MSC7x0x controller Inductive sensors (LVDT)]()

- induSENSOR EDS

![induSENSOR EDS Inductive sensors (LVDT)]() Long-stroke sensors with integrated electronics

Long-stroke sensors with integrated electronics - Customer-specific sensors for OEM and series applications

![Customer-specific sensors for OEM and series applications Inductive sensors (LVDT)]()

- induSENSOR DTD gauge

- Magneto-inductive sensors

- mainSENSOR MDS-35/-45

![mainSENSOR MDS-35/-45 Magneto-inductive sensors]() Robust sensors with M12, M18 and M30 design

Robust sensors with M12, M18 and M30 design - mainSENSOR MDS-40-MK

![mainSENSOR MDS-40-MK Magneto-inductive sensors]() Sensors for series applications

Sensors for series applications - mainSENSOR MDS-40-LP

![mainSENSOR MDS-40-LP Magneto-inductive sensors]() Sensors with circuit-board design

Sensors with circuit-board design - Customer-specific sensors

![Customer-specific sensors Magneto-inductive sensors]()

- mainSENSOR MDS-35/-45

- Draw-wire sensors

- Draw-wire sensors for serial integration & OEM

![Draw-wire sensors for serial integration & OEM Draw-wire sensors]() Miniature sensors with plastic housing

Miniature sensors with plastic housing - Industrial draw-wire sensors

![Industrial draw-wire sensors Draw-wire sensors]() Robust sensors with aluminum housing

Robust sensors with aluminum housing - Draw-wire sensors for fast measurements

![Draw-wire sensors for fast measurements Draw-wire sensors]() For high wire accelerations

For high wire accelerations - Mechanics

![Mechanics Draw-wire sensors]() Draw-wire mechanisms for encoder mounting

Draw-wire mechanisms for encoder mounting

- Draw-wire sensors for serial integration & OEM

- Inductive sensors (eddy current)

- Industry sensors

- Rotation speed sensors

- Infrared pyrometer

- thermoMETER UC

![thermoMETER UC Infrared pyrometer]() High-performance industrial pyrometer

High-performance industrial pyrometer - thermoMETER SE

![thermoMETER SE Infrared pyrometer]() Robust miniature pyrometer

Robust miniature pyrometer - thermoMETER FI

![thermoMETER FI Infrared pyrometer]() Fully integrated compact pyrometer

Fully integrated compact pyrometer - Pyrometers for special applications

![Pyrometers for special applications Infrared pyrometer]()

- thermoMETER UC

- Thermal imaging cameras

- Color measuring systems, color sensors and LED Analyzers

- Fiber optic sensors

- Interface and signal processing units

- 2D/3D measurement

- 3D sensors

- Optical precision micrometer

- optoCONTROL 1200

![optoCONTROL 1200 Optical precision micrometer]() Compact high-speed micrometer

Compact high-speed micrometer - optoCONTROL 2520

![optoCONTROL 2520 Optical precision micrometer]() Compact laser micrometer (class 1M)

Compact laser micrometer (class 1M) - optoCONTROL 2700

![optoCONTROL 2700 Optical precision micrometer]() High-performance micrometer for the highest demands

High-performance micrometer for the highest demands

- optoCONTROL 1200

- Laser profile scanners

- Configurator

- scanCONTROL 25x0

![scanCONTROL 25x0 Laser profile scanners]() Laser scanner for series applications

Laser scanner for series applications - scanCONTROL 29x0

![scanCONTROL 29x0 Laser profile scanners]() Compact laser scanners with high precision

Compact laser scanners with high precision - scanCONTROL 30x2

![scanCONTROL 30x2 Laser profile scanners]() Powerful 2D/3D laser scanners

Powerful 2D/3D laser scanners - scanCONTROL 30x0

![scanCONTROL 30x0 Laser profile scanners]() High-performance laser scanners

High-performance laser scanners - Software

- Options & Accessories

- Applications

- Measuring systems

- Sensor systems for precise 3D and thickness measurement

- thicknessGAUGE 3D

![thicknessGAUGE 3D Sensor systems for precise 3D and thickness measurement]() Inline thickness and profile measurements

Inline thickness and profile measurements - thicknessGAUGE C.LL

![thicknessGAUGE C.LL Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (laser sensors)

Inline thickness measurement (laser sensors) - thicknessGAUGE C.C

![thicknessGAUGE C.C Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (confocal)

Inline thickness measurement (confocal) - thicknessGAUGE C.LP

![thicknessGAUGE C.LP Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (laser profile sensors)

Inline thickness measurement (laser profile sensors) - thicknessGAUGE O.EC

![thicknessGAUGE O.EC Sensor systems for precise 3D and thickness measurement]() Inline thickness measurement (eddy current/capacitive)

Inline thickness measurement (eddy current/capacitive)

- thicknessGAUGE 3D

- Measuring and inspection systems for metals

- Measuring and inspection systems for the automotive industry

- Measuring systems for the battery production

- Inspection and production systems for the tire industry

- Gauges and inspection systems for plastics

- Sensor systems for precise 3D and thickness measurement

- Applications

- Industries

- Additive Manufacturing

- Aerospace

- Automation

- Automotive

- Battery production

- Structural monitoring & Building material production

- Electronics production

- Energy technology

- Glass

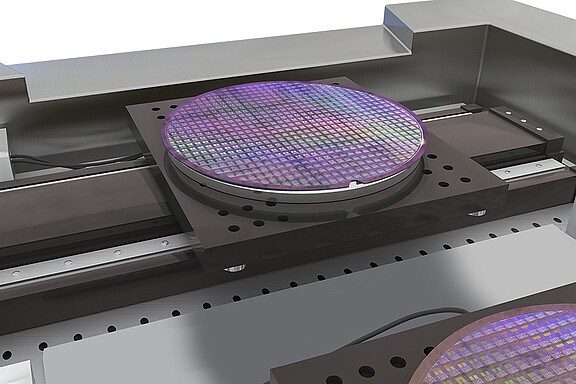

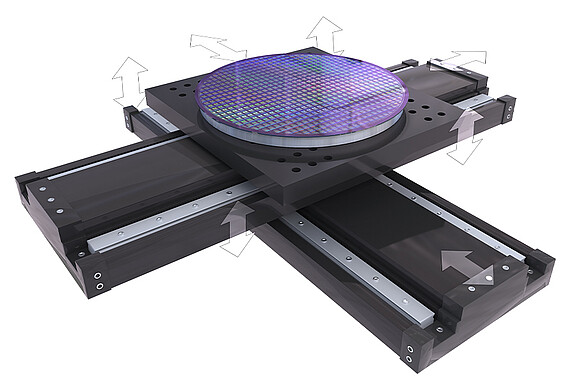

- Semiconductors & Wafers

- Plastics

- Paint inspection

- Machine building

- Medical technology

- Measurement & Testing technology

- Metal production

- Mobile machines

- Precision optics

- Tracks & Rail traffic

- Welding automation

- Search by measurement

- Industries

- Contact