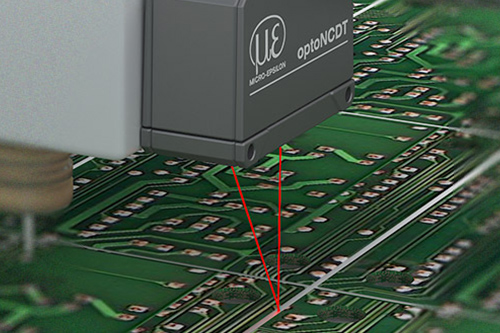

Electronics production

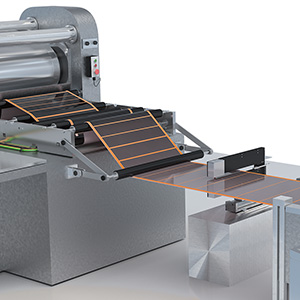

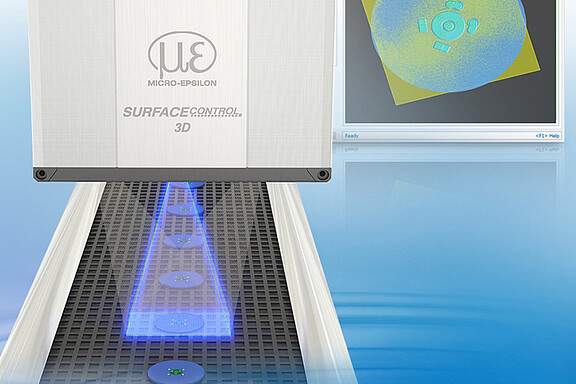

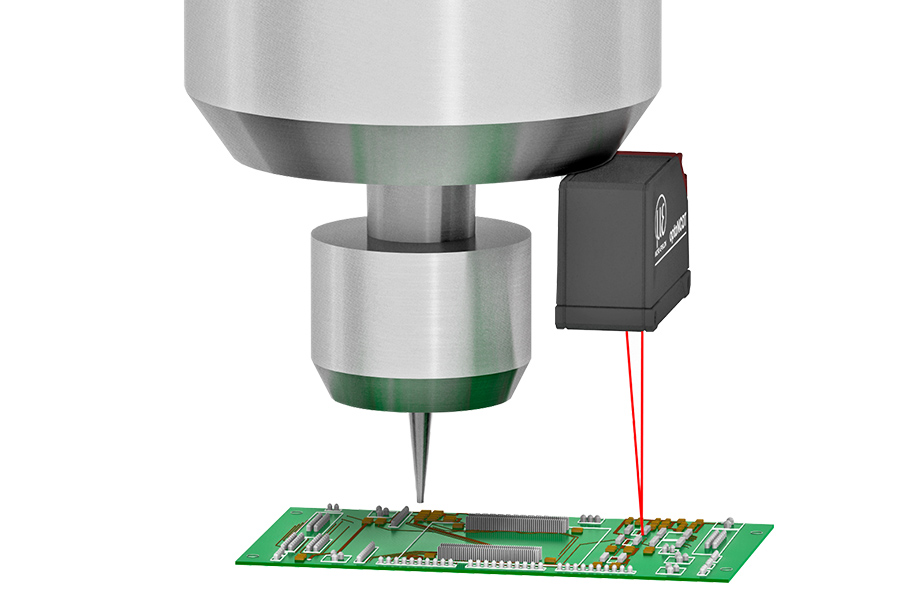

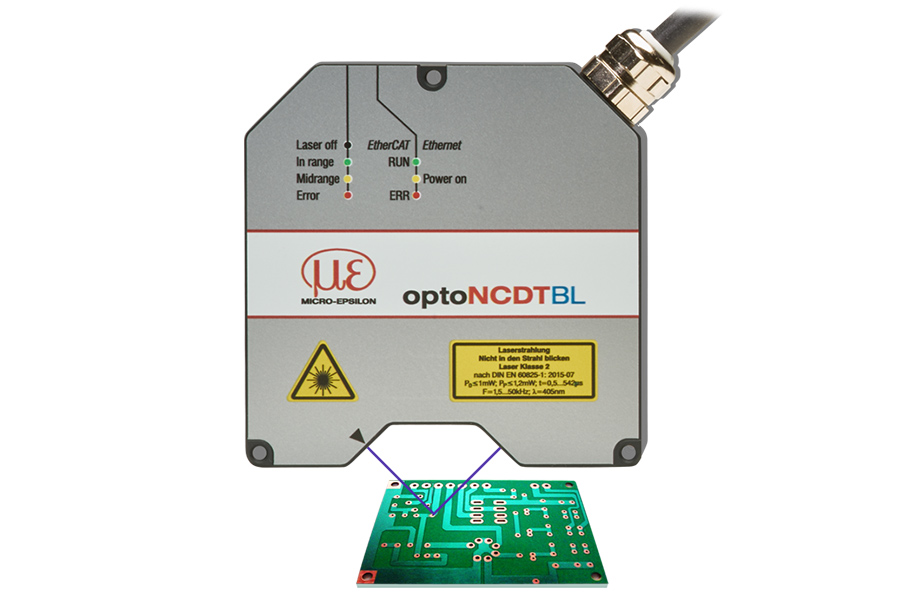

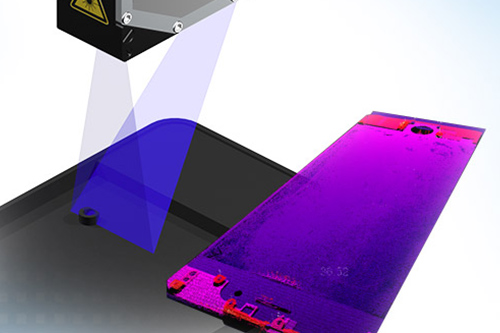

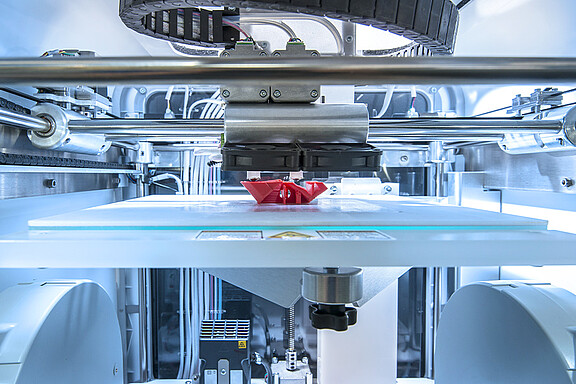

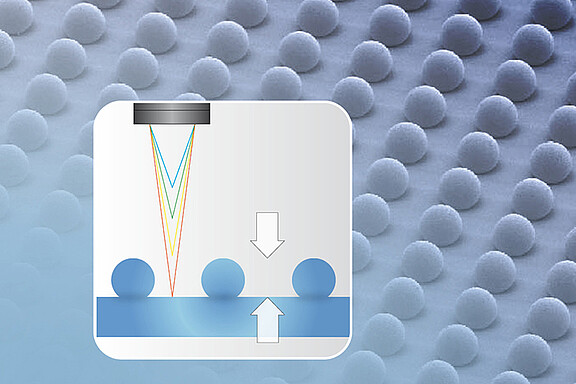

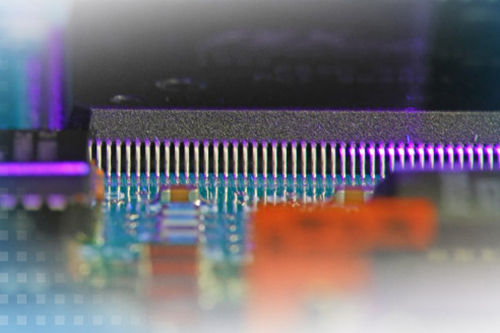

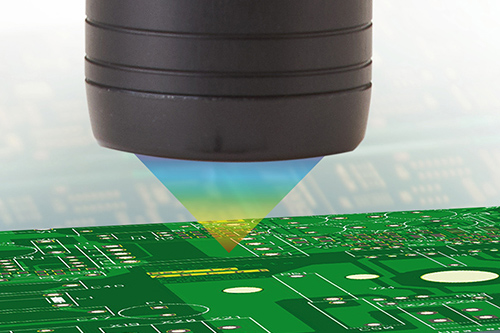

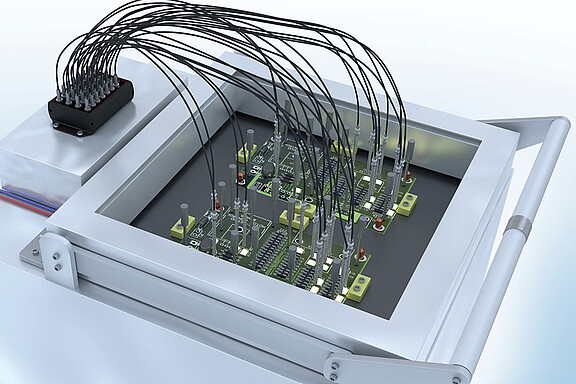

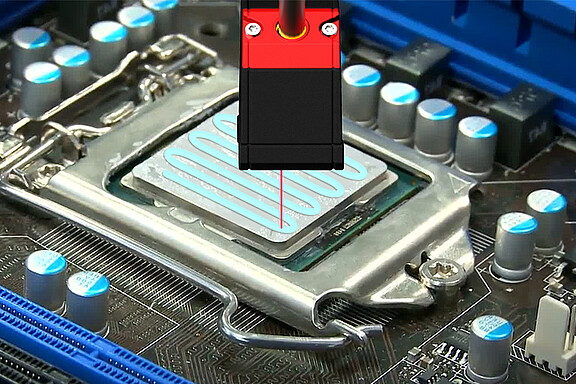

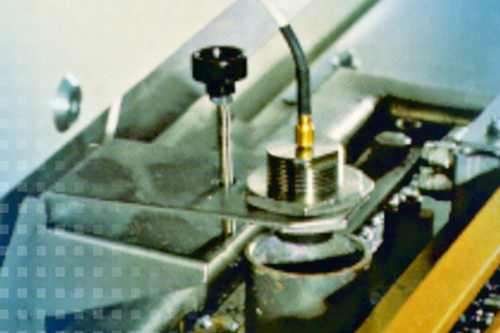

In the electronics industry, increasing miniaturization and high production speeds are accompanied by highest quality standards. Sensors from Micro-Epsilon are used in high-tech production machines and production facilities and ensure that the high quality and requirements in terms of quality and efficiency are met. Thanks to the variety of models and the high precision of non-contact displacement sensors, Micro-Epsilon is a partner in almost all areas of the electronics industry - from chip production to complex assembly monitoring in the production of computers, smartphones and tablets.