Dimensions, tolerances, sorting, part recognition

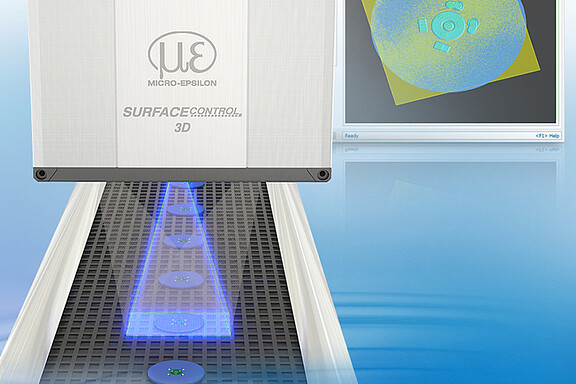

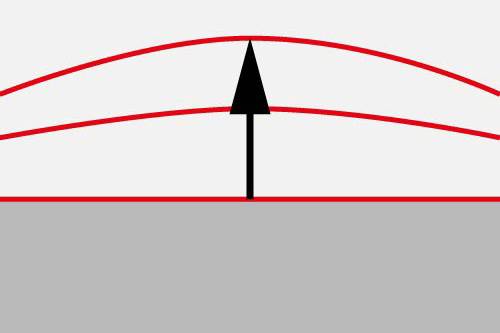

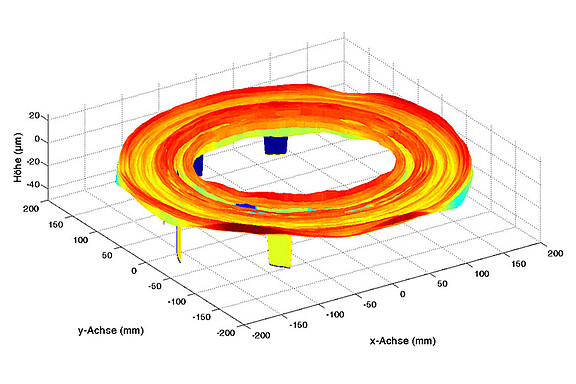

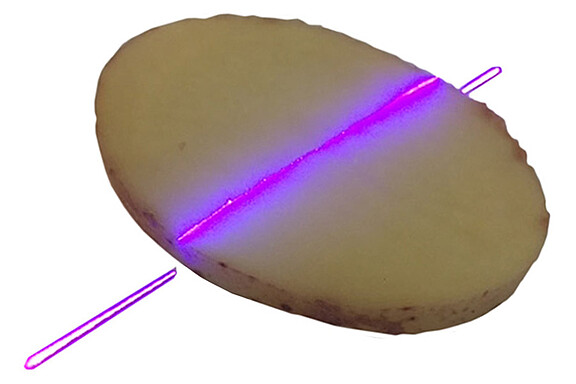

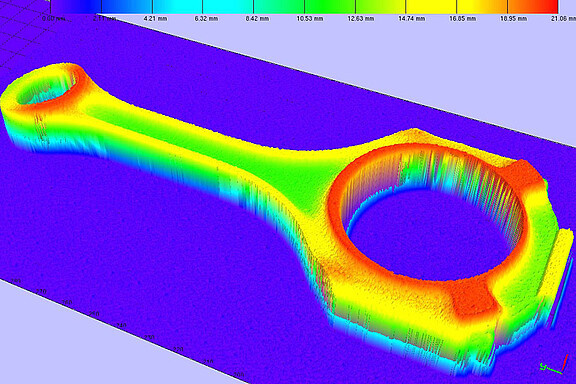

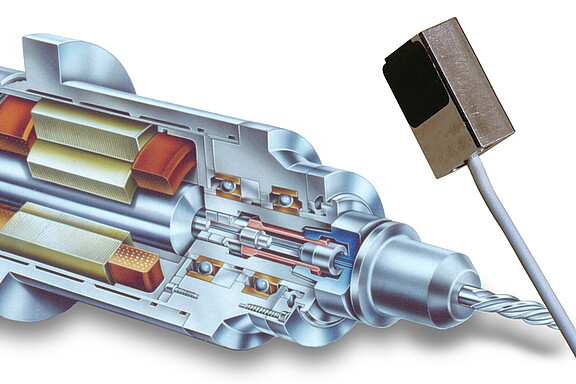

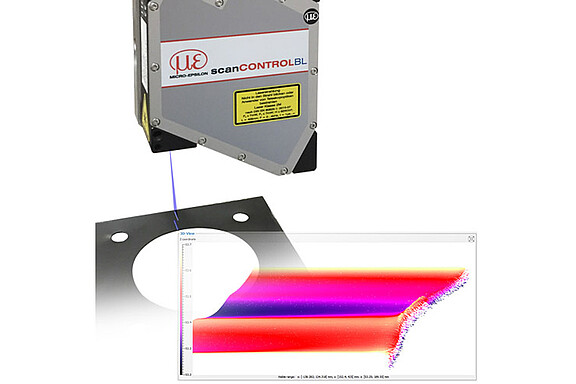

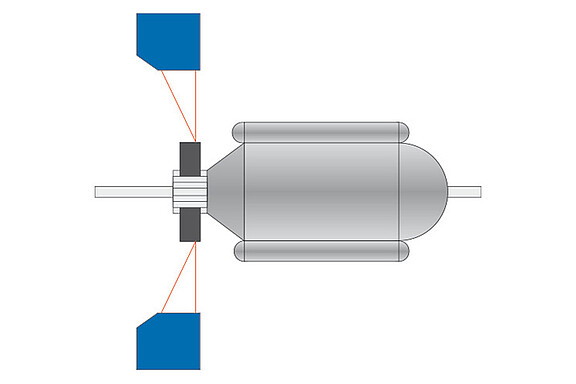

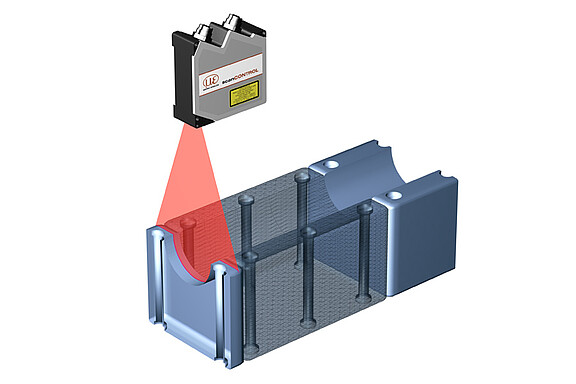

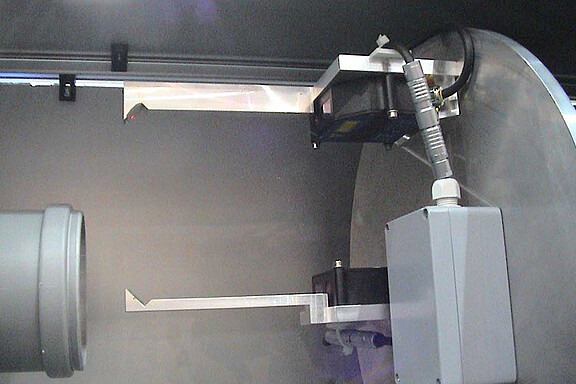

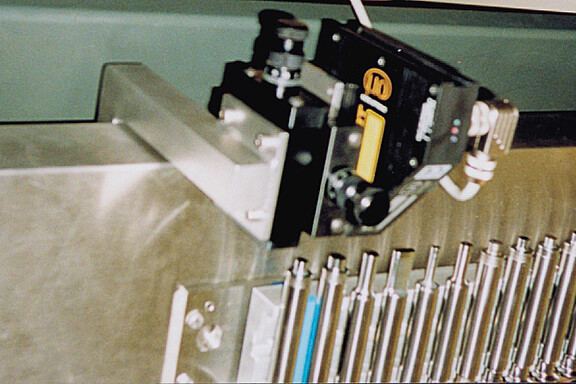

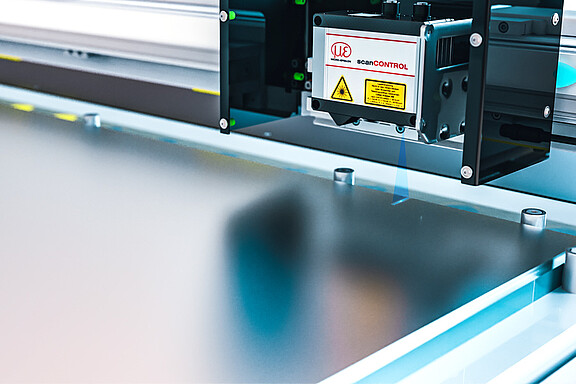

Dimensions usually designate the significant linear dimensions of an object. Dimensions can be measured in different ways. Under certain circumstances, one sensor can measure the complete dimensions for small objects. Image processing systems, laser profile sensors and ThruBeam micrometers are particularly capable of detecting complete dimensions.

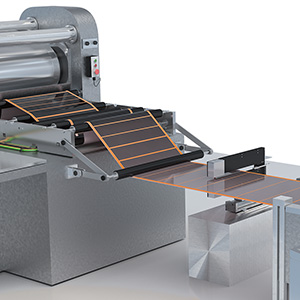

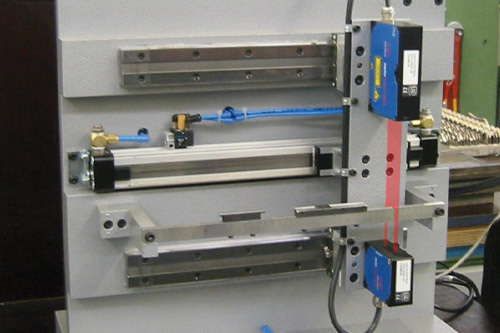

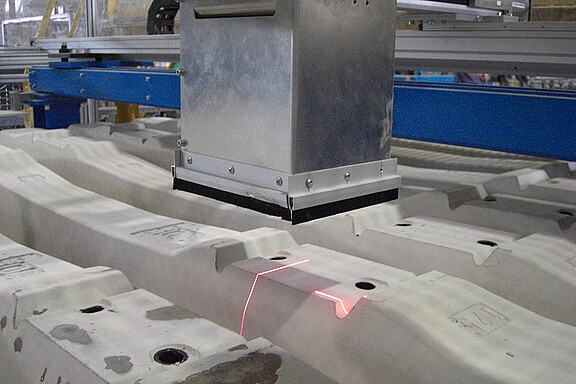

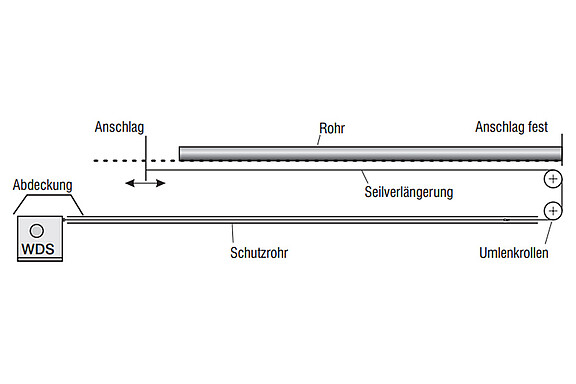

For larger measuring objects, the measurement can be performed using sensors which move along one edge of the target and thus measure the object dimensions. One alternative to this is that the dimension is measured with a static sensor and moving measuring objects as is typically the case for assembly lines.