Thickness measurement with sensors and sensor systems

Thickness is an essential parameter in R&D as well as in industrial production. Sporadic measurements can be performed manually, but these reach their limits when high measurement accuracy is required, the production process must not be interrupted or critical environments are present. To perform non-contact thickness measurements with high precision, Micro-Epsilon offers displacement sensors and measuring systems for use in various industries. Here, a distinction is made between a one-sided and a two-sided thickness measurement. With one-sided thickness measurements, the sensor determines the target thickness from one side only. Two-sided thickness measurements are performed using at least one pair of sensors mounted opposite each other in one axis.

Advantages of Micro-Epsilon solutions for industrial thickness measurements

- Precision: Measurements with micrometer accuracy

- Efficiency: Automated solutions save time and money.

- Flexibility: Our sensors are suitable for numerous materials and applications.

- Reliability: Robust technologies for continuous operation in harsh environments

- Unsurpassed: Whether sensor or measuring system for thickness measurement – we always find the best solution for your measurement task.

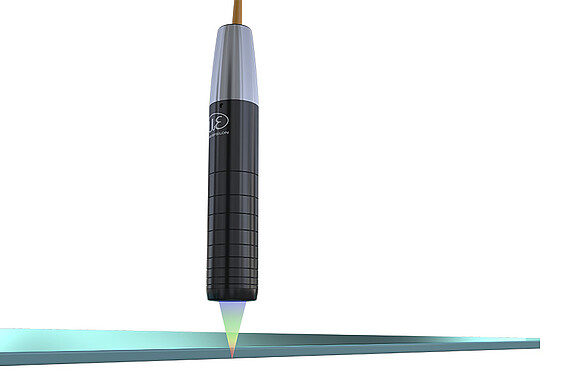

One-sided thickness measurement of transparent materials with confocal sensors

Confocal sensors enable one-sided thickness measurement of transparent materials such as display glass. This means that only one sensor is required for thickness measurement. Confocal chromatic sensors from Micro-Epsilon evaluate up to 6 peaks during the measurement, allowing them to monitor single layers and gaps. The latest sensor generation even detects material thicknesses from just 5 µm.

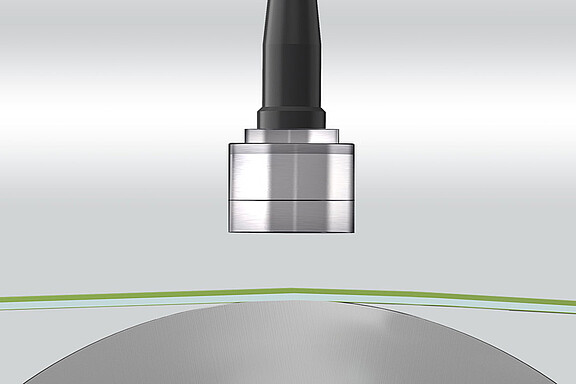

One-sided thickness measurement of films

Intended for difference thickness measurements of plastics and adhesives, the combiSENSOR accommodates an eddy current sensor and a capacitive displacement sensor in one housing. A metallic counter electrode is required (usually a transport roller), which forms the reference distance. The integrated capacitive sensor detects the distance from the non-conductive plastic or adhesive layer, while the eddy current sensor measures the distance from the metallic object. The controller calculates the thickness with extremely high accuracy from both sensor signals. The combiSENSOR measures even very thin materials from 40 µm.

One-sided thickness measurement of electrode coatings

The combiSENSOR KSB6430 measures the thickness of electrode coatings at ambient temperatures up to 180 °C. This precise sensor combines the advantages of eddy current and capacitive sensor technology in a single housing. The thickness is measured on a roller which guides the material. Due to its robust design and high accuracy, the combiSENSOR is ideal for inline thickness monitoring in battery film coating processes.

Learn more about one-sided thickness measurement of electrode coatings

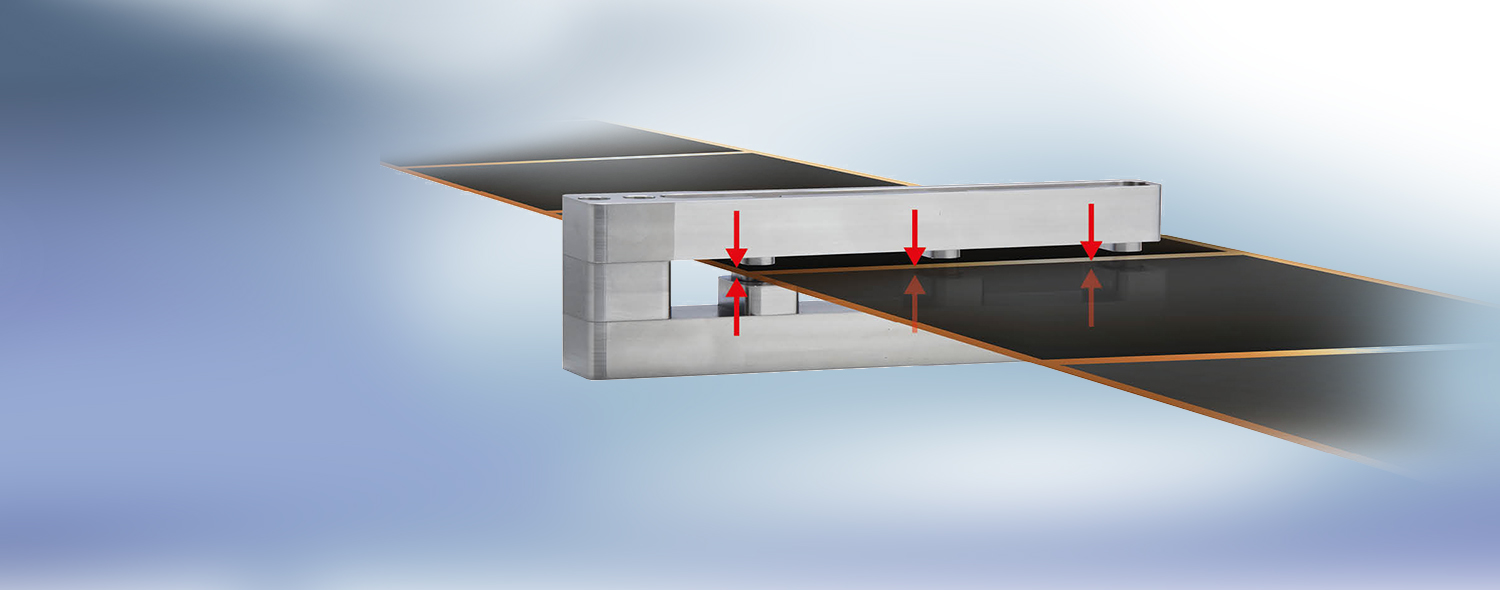

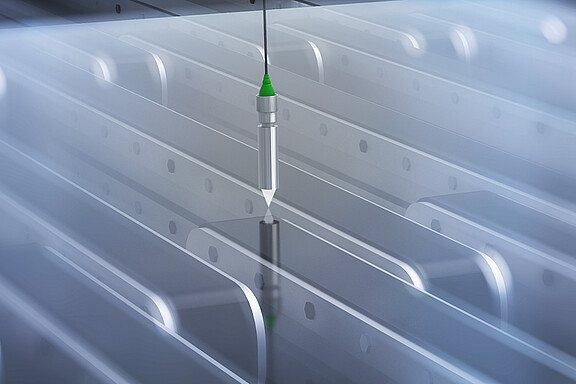

Two-sided thickness measurement with capacitive displacement sensors

For highly accurate thickness measurements of electrically conductive materials, capacitive displacement sensors can be used, which are arranged opposite to one another. The intelligent controller processes and calculates the sensor signals so that the thickness measurements can be output directly. With the two-sided thickness measurement, the thickness of very thin measuring objects such as silicon wafers and coated battery films can be measured with high accuracy and stability.

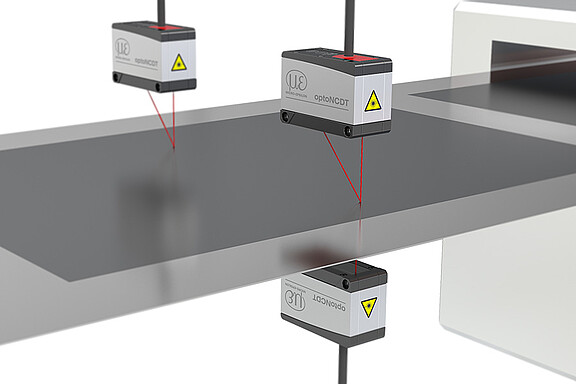

Two-sided thickness measurements with laser sensors

Laser displacement sensors arranged on two sides detect the thickness of different objects according to the differential thickness method. Non-contact thickness measurement works with various materials, e.g. plastics, metals, wood and coated glass. The sensors must be synchronized and precisely aligned in order to obtain accurate measurement results. Depending on the measuring range, the sensors can be aligned at a large distance from each other.

The thicknessSENSOR is a turnkey sensor system that can be used for this type of thickness measurement.

Systems for thickness measurements of black rubber webs

For thickness and thickness profile measurements of tire components and rubber sheets, Micro-Epsilon offers industry-specific measuring systems and profilometers for integration into the production line. These turnkey systems are available with application-specific sensors, extensive interfaces and software packages.

Learn more about measuring systems for tires and rubber

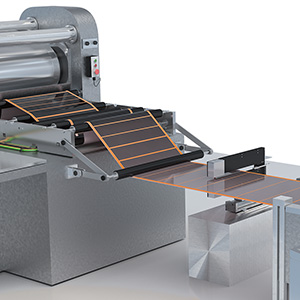

Systems for thickness measurement of plastics

The thickness of films and thin plastics can be measured with Micro-Epsilon’s turnkey systems that are integrated directly into the production line. These systems are designed for inline thickness measurements of plastic films from 10 μm. Depending on the installation site, the measuring systems are equipped with application-specific sensors, interfaces and software packages.

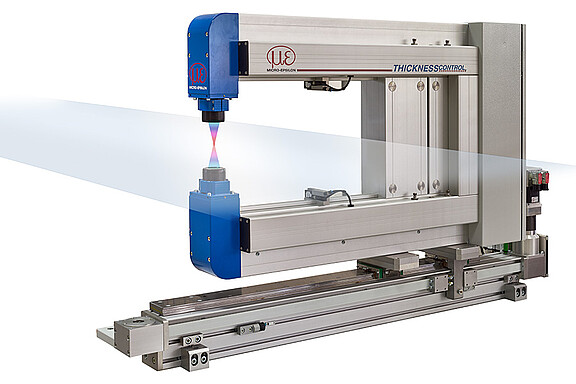

Systems for thickness measurement of metal strips and plates

Thickness monitoring of metal strips and plates can be solved using Micro-Epsilon’s measuring systems and optical gauges with application-specific sensors. Depending on the version, these measuring systems are used for non-contact thickness measurement in cold and hot rolling mills. O-frame systems are intended for traversing monitoring of the strip width, while C-frame systems measure the thickness of individual tracks. These systems cope with each and every surface and alloy, therefore being the perfect choice for various applications.

Systems for thickness measurements of metal strips and plates

For thickness monitoring of metal strips and metal plates, Micro-Epsilon offers measuring systems and optical gauges with application-specific sensors. Depending on the version, these measuring systems are used for non-contact thickness measurement in cold and hot rolling mills. O-frame systems are intended for traversing monitoring of the strip width, while C-frame systems measure the thickness of individual tracks. These systems cope with each and every surface and alloy, therefore being the perfect choice for various applications.

Learn more about metal thickness measuring systems from Micro-Epsilon.

Stable thickness measurement with white light interferometers

The IMS5400-TH white light interferometer is used for highly accurate thickness measurements from a relatively large distance. A decisive advantage here is the distance-independent measurement, where a nanometer-accurate thickness value is achieved even with moving objects. The large thickness measuring range allows the measurement of thin layers, flat glass and films. With the multi-peak controller version, up to 5 layers or air gaps can be measured simultaneously. This enables multi-layer thickness measurement of transparent objects, coatings and laminated glass.

Learn more about thickness measurements with white light interferometers

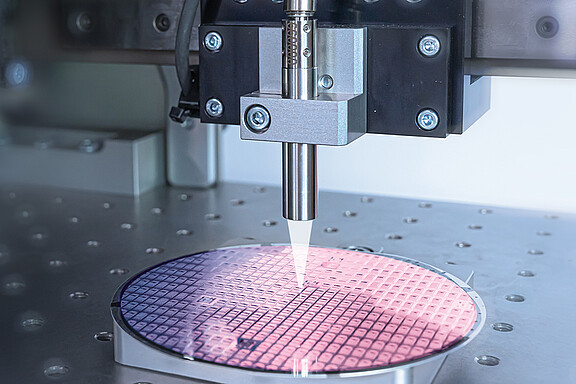

Thickness measurement of silicon wafers with white light interferometers

The IMS5420 interferometer enables the thickness measurement of undoped, doped and highly doped silicon wafers. The wafer thickness interferometer measures the thickness of silicon wafers from 500 to 1050 µm. Even with highly doped wafers, thicknesses up to 0.8 mm can be measured. The interferometer is also available as a multi-peak thickness measuring system. This multi-peak system measures thicknesses of up to five layers, e.g., wafer thickness, air gap, films and coatings.

Learn more about thickness measurements of silicon wafers with white light interferometers

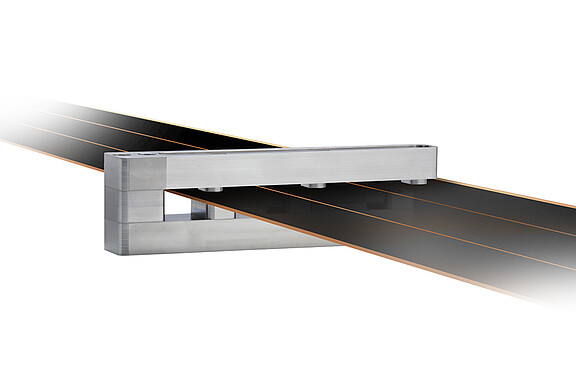

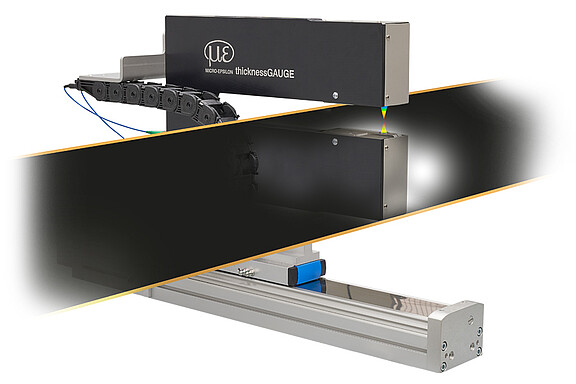

Sensor systems for precise thickness measurement of strips and sheets

The thicknessGAUGE sensor systems are fully assembled systems consisting of a sturdy frame with two optical distance sensors attached to it. Several models with different sensor types, measuring ranges and measuring widths enable the inline thickness measurement of different materials and surfaces.

Learn more about precise thickness measurement of strips and sheets with sensor systems

FAQ

Our sensors reliably measure the thickness of metals, plastics, glass, paper, textiles and coatings. Depending on the sensor technology (e.g. laser, confocal, capacitive), they are suitable for different types of materials and surfaces.

Non-contact thickness measurement prevents mechanical wear, enables high-precision measurements without influencing the material and provides immediate results for automated processes – ideal for inline quality control and production monitoring.