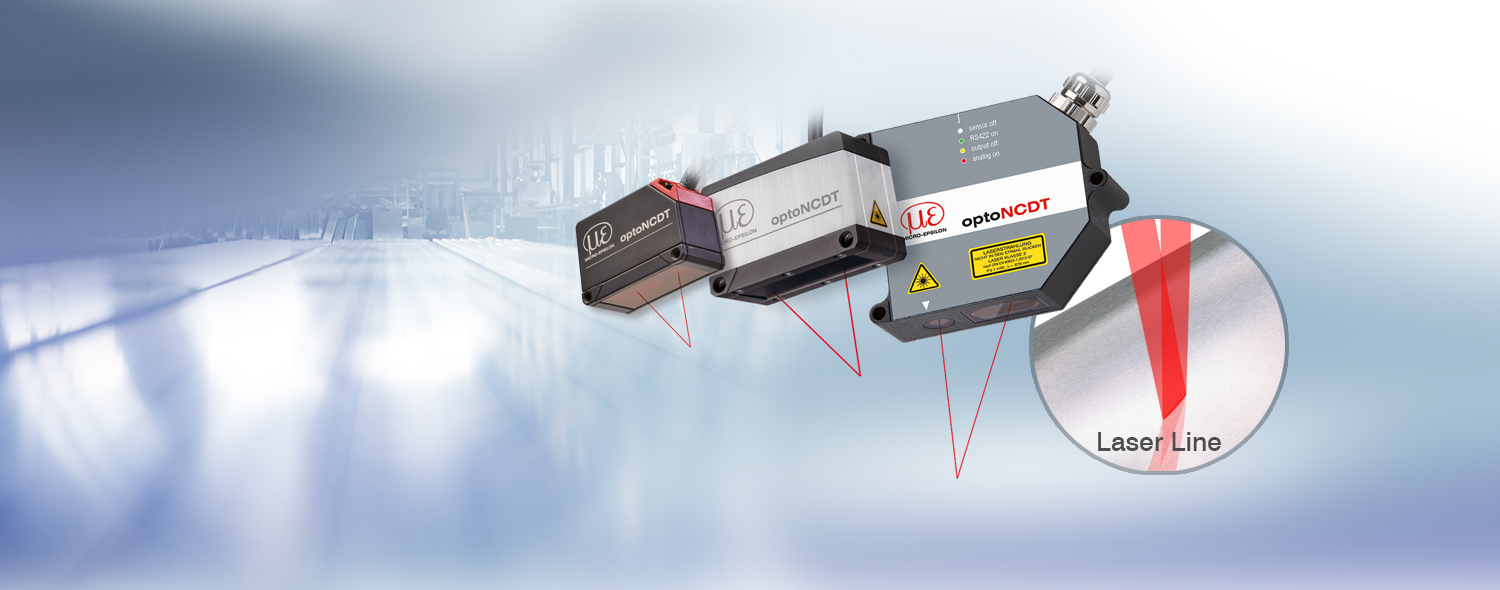

Laser sensors for metals and rough surfaces

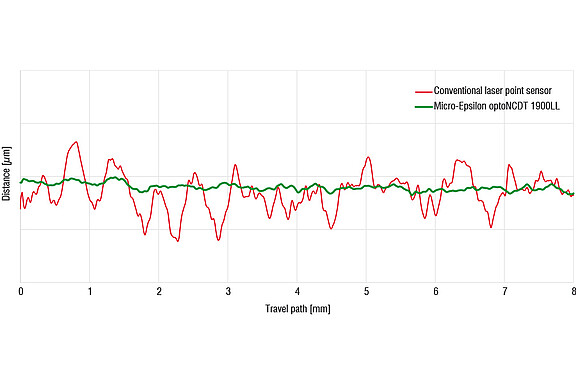

The optoNCDT LL laser sensors produce an oval-shaped light spot of just a few millimeters in width which reminds of a short "laser line" (LL). This oval light spot compensates for inhomogeneous surface structures and the so-called "speckling" effect which particularly occurs with metallic surfaces. Combined with special software algorithms, interferences caused by surface roughness, defects, indentations or holes are filtered out. This enables stable and precise measurement results.

Reliable measurements on structured and metallic surfaces

The optoNCDT LL laser sensors are available in several series with different measuring ranges, measuring rates and accuracies. They are used for precise distance measurements on structured surfaces, i.e. when the distance to the surface and not the structure itself needs to be measured. For fine details and surface structures, the optoNCDT sensors with a point-shaped laser and the Blue Laser sensors are the preferred choice.

Interface and signal processing units

The compact optoNCDT 1420 LL laser sensors are designed for measurements of shiny metallic and rough surfaces. The oval light spot, which resembles a short laser line, can better compensate for unevenness such as texture and roughness. Special software algorithms filter out interference caused by surface roughness, defects, depressions or the smallest holes.

- Laser sensor with special lens with oval light spot (short laser line)

- Precise measurement on metal surfaces and structured surfaces

- Active Surface Compensation for changing surfaces (ASC)

- Integrated controller

- Measuring range (mm): 10 | 25 | 50

- Linearity from 8 µm

- Adjustable measuring rate up to 8 kHz

- Digital interface (integrated): RS422 (16 bit)

- Digital interfaces (optional connection via interface module): PROFINET, EtherNet/IP, EtherCAT

- Scalable analog output

- Robust aluminum housing with IP67

optoNCDT 1900 LL laser sensors are designed for the measurement of shiny metallic and rough surfaces. Their small laser line enables precise measurement results with shiny metallic surfaces and structured objects. Due to their extremely compact size, the sensors can also be integrated into restricted installation spaces.

- Laser sensor with special lens and oval light spot (small laser line)

- Ideal for static and dynamic distance measurements on metals, structured surfaces and measuring objects where the laser beam penetrates

- Compact sensor design with integrated controller

- High resistance to ambient light

- Measuring ranges (mm): 2 | 6 | 10 | 25 | 50

- Linearity from 1 µm

- Repeatability 0.1 µm

- Adjustable measuring rate up to 10 kHz

- Interfaces: analog output, RS422, PROFINET, Ethernet/IP, EtherCAT

- Advanced Surface Compensation for surfaces with changing reflections

- Data sheet optoNCDT 1900LL (pdf, 2.42 MB)

- Data sheet optoNCDT 1900LL with integrated Industrial Ethernet interface (pdf, 2.81 MB)

- Setup Guide optoNCDT 1900 / 1900LL (pdf, 2.27 MB)

- Setup Guide optoNCDT 1900-Industrial Ethernet (pdf, 1.36 MB)

- Operating Instructions optoNCDT 1900 (pdf, 8.42 MB)

- Operating Instructions optoNCDT 1900-EtherCAT (pdf, 5.22 MB)

- Operating Instructions optoNCDT 1900 EtherNet/IP (pdf, 5.38 MB)

- Operating Instructions optoNCDT 1900 PROFINET (pdf, 5.89 MB)

- Setup Guide Protective Film optoNCDT 1900 (pdf, 662.70 KB)

- CAD file 3D-model optoNCDT ILD1900 (zip, 18.50 MB)

- Electronic Data Sheet file optoNCDT 1900 (zip, 4.98 KB)

- Firmware update ILD1900 V18.0 (U_18.0-97) (zip, 2.32 MB)

- Firmware update for ILD1900-EtherCAT V1 (U-ECAT_20.02-107) (zip, 2.99 MB)

- ESI Device Description for ILD1900-EtherCAT (zip, 7.70 KB)

- Firmware update for ILD1900-EtherNet/IP V1 (U-ENIP_14.0-14.0-85) (zip, 3.58 MB)

- ESD Device Description for ILD1900-EtherNet/IP (zip, 5.05 KB)

- Firmware update ILD1900-PROFINET version 014.000 (zip, 3.61 MB)

- sensorTOOL V2.1.1 (exe, 17.85 MB)

- MEDAQLib V5.3.1 (zip, 22.86 MB)

Instead of a common laser point, optoNCDT 2300LL laser sensors project a very small laser line onto the target surface. This laser line makes the optoNCDT 2300LL particularly suitable for precise displacement and distance measurements both on shiny, porous and rough surfaces. The high measuring rate up to 49 kHz enables reliable measurements in high speed processes. Parameter setting of the laser sensor is via a web interface that is addressed via an Ethernet interface. This web interface offers many features for the evaluation and processing of measured values and signals.

- Laser sensor with special lens and oval light spot (small laser line)

- Ideal for static and dynamic distance measurements on metals, structured surfaces and measuring objects where the laser beam penetrates

- Integrated controller

- Measuring ranges (mm): 2 | 10 | 20 | 50

- Linearity from 0.6 µm

- Resolution max. 0.03 µm

- Adjustable measuring rate up to 49.140 kHz

- Advanced Real-Time-Surface-Compensation (A-RTSC)

- Interfaces: Ethernet, EtherCAT, RS422, Profinet, EtherNet/IP, analog output (via C-Box)