Multi-segment measurement on superconducting strips

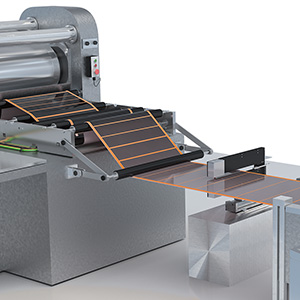

The production of superconducting strips for power applications requires the highest precision and the greatest possible protection of the material. Typically, 12 mm wide stainless-steel strips are processed with a nickel alloy and are cut into several narrow strips – for example, into 3 or 4 mm wide segments, separated by gaps of only 0.5 mm. As the strips also have sensitive PVD coatings, the width and segment measurements must be non-contact and highly accurate.

Real-time quality control for maximum process reliability

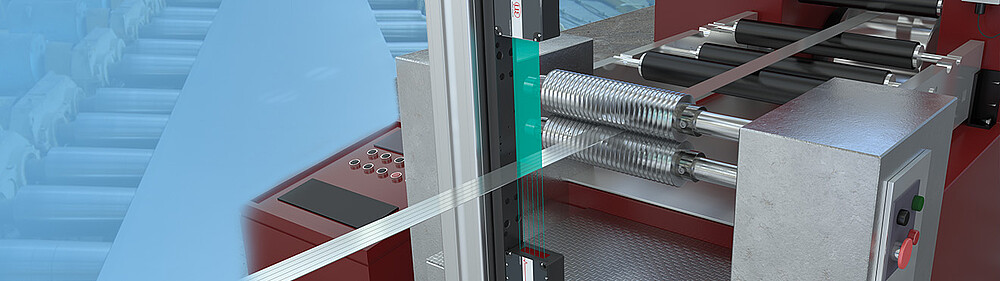

With the optoCONTROL 2700-40 from Micro-Epsilon, the strip is measured directly after cutting as the process continues to run. The endless strip with a width of 12 mm is detected in the field of view of the optical micrometer. Thanks to the “Multi-segment” preset, both the total width and the width of the individual subsections can be measured precisely. Even the narrow 0.5 mm gaps between the segments are reliably detected and monitored. As the measurement results are transmitted to the line PLC in real-time, the measured values can be used immediately for process control.

Maximum precision with minimal waste

The optical precision micrometers offer a number of decisive advantages for demanding cutting and coating processes. Since the measurement is non-contact, the sensitive nickel and PVD coatings are not subjected to mechanical stress, so there is no risk of scratches or deformation. At the same time, the optoCONTROL 2700-40 micrometers stand out for their extreme precision: With a resolution of 10 nm and a repeatability of ≤ 0.1 µm, even extremely narrow strips can be reliably detected. With a measuring rate of 5 kHz, these sensors enable fast and seamless monitoring of the running strips so that deviations are detected immediately and waste is minimized. Using flexible interfaces such as EtherCAT, PROFINET, Ethernet/IP or analog signals, the system can also be seamlessly integrated into existing cutting and production systems.