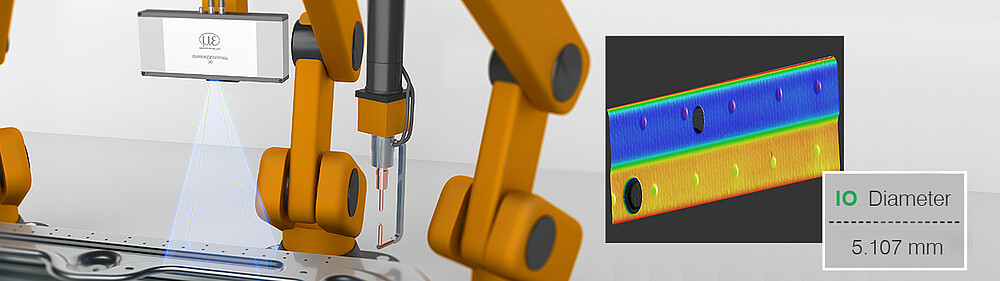

Geometry inspection during spot welding

In car body production, the quality of the spot welds is a decisive criterion for stability and safety. Classic 2D vision systems quickly reach their limits here, as they only provide contrast information and do not allow reliable statements to be made about the geometric characteristics of the spot welds. The surfaceCONTROL 3D snapshot sensors, on the other hand, capture the complete geometry of the welding spot as a high-resolution point cloud in a single measurement process. This allows parameters such as height, diameter, shape and position to be precisely determined and automatically compared with the target values. Deviations or faulty points are detected immediately so that rework or waste can be minimized.

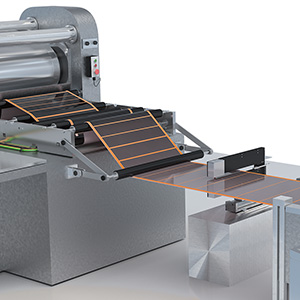

Fast inline geometry inspection

Since multiple weld spots can be measured simultaneously, the testing process is significantly accelerated. As this is high speed measurement, the surfaceCONTROL 3500 sensors can be integrated directly inline into the production process - without slowing down the production flow. The 3D sensors therefore make a significant contribution to process reliability and enable consistently high quality in spot weld inspection.