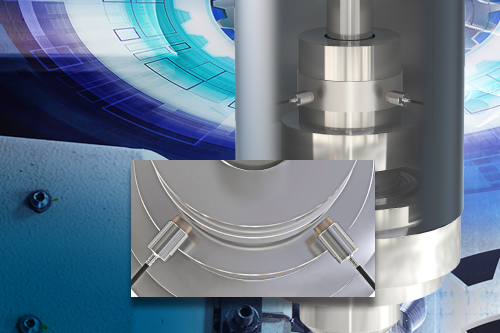

Measuring the spindle runout

In high-frequency spindles, the accurate concentricity or shaft runout of the tool play a decisive role. Non-contact, inductive displacement sensors from Micro-Epsilon are used for monitoring of concentricity or shaft runout. Based on the eddy current technology, these sensors provide high resolution despite oil and dirt in the installation space. This is how the measurement accuracy in the micrometer range is achieved. The high frequency response even enables the monitoring of high-frequency spindles with rotational speeds > 120,000 rpm. In this measurement process, the eddyNCDT 3005 measuring system performs a non-contact measurement onto an aluminum ring which is shrunk onto the axis. Two sensors shifted radially by 90° measure the distance from the spindle in order to transmit the values to the control system.