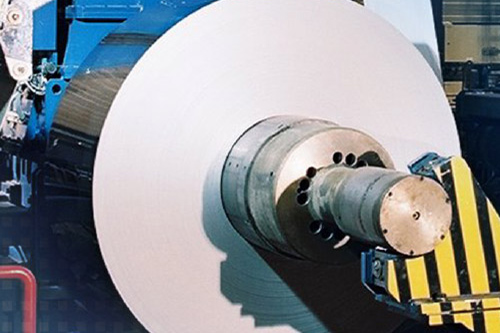

Machine building

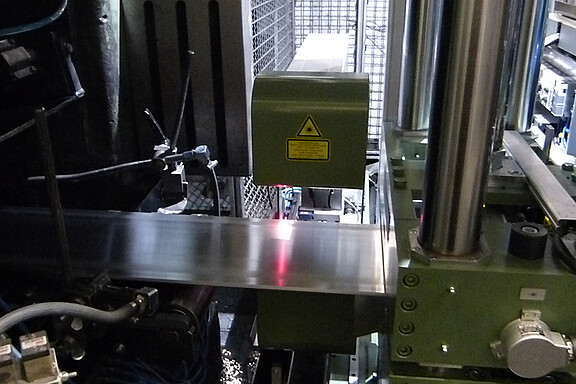

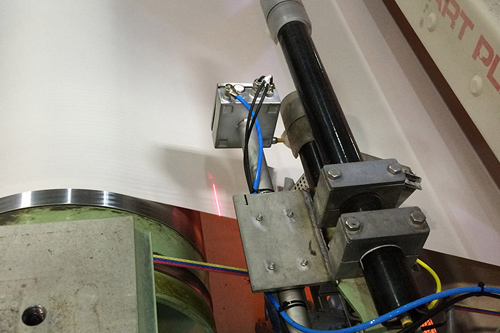

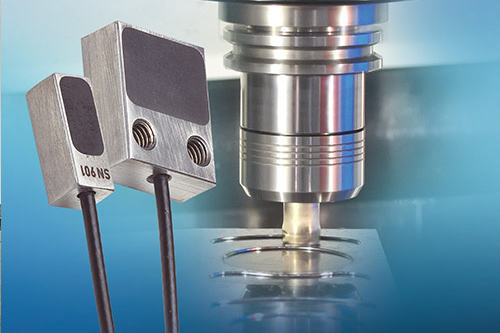

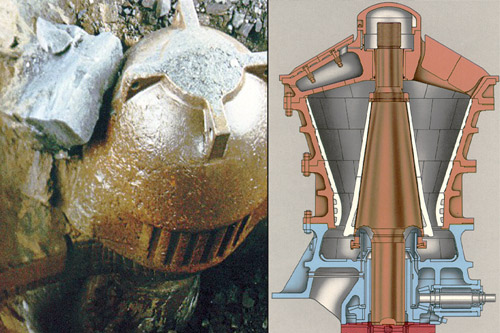

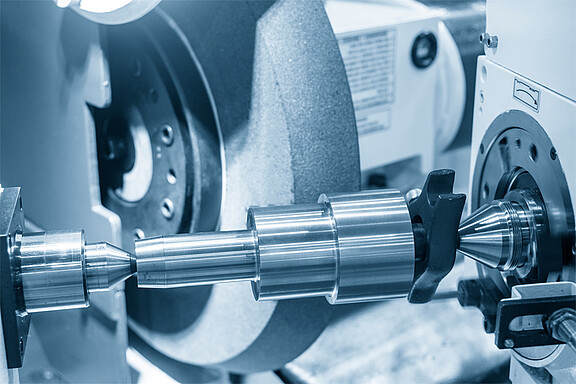

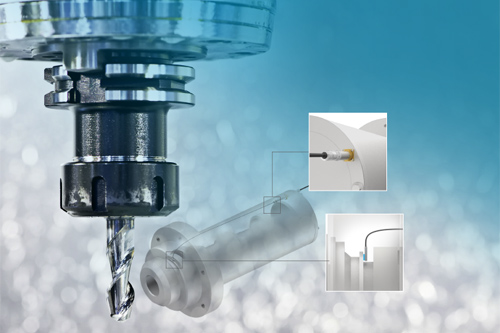

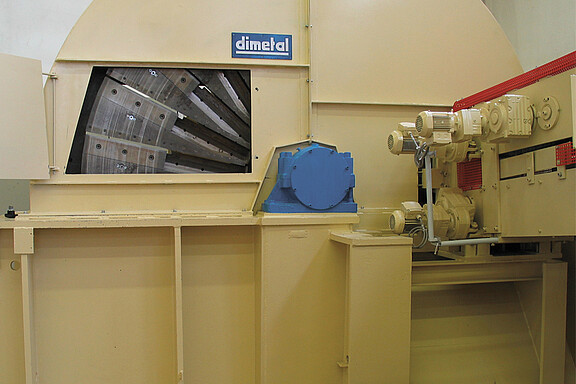

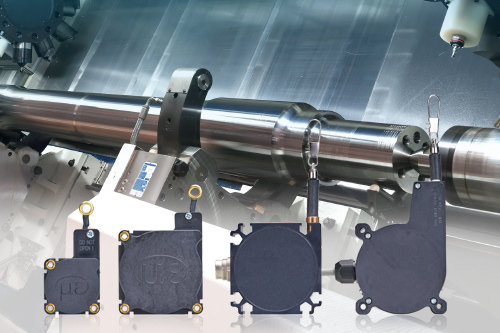

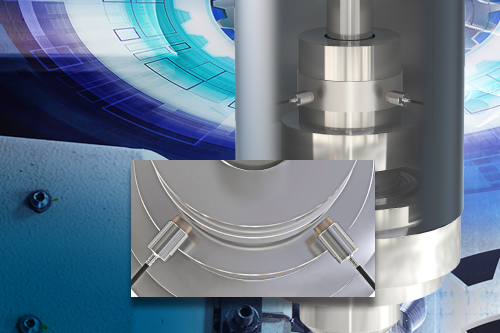

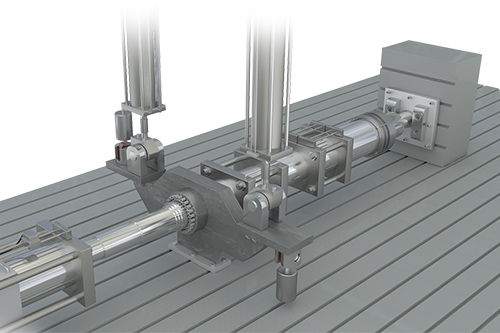

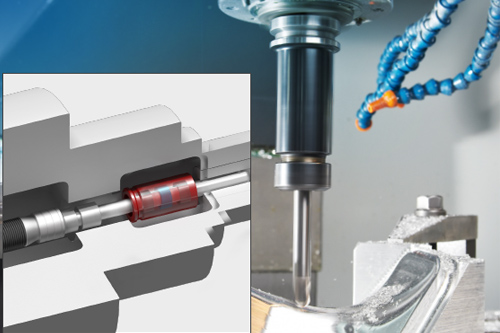

As a long-standing partner in machine building and machine design, Micro-Epsilon offers a wide range of sensors and measuring systems. Miniaturized and integrated into machines, displacement sensors measure machine movements, positioning and travel paths and ensure safe machine operation. For automated machines and process-integrated machines, Micro-Epsilon sensors monitor a wide range of sizes of manufactured products.

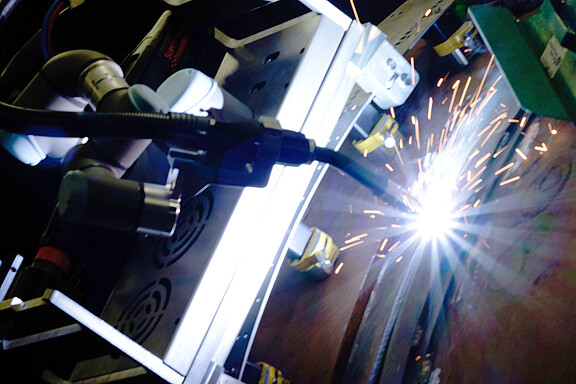

Particularly where harsh ambient conditions such as oil, dirt, pressure, vibrations and temperatures are present, sensors from Micro-Epsilon convince with high precision and favorable conditions.