Laser profile scanner for cockpit assembly in cars

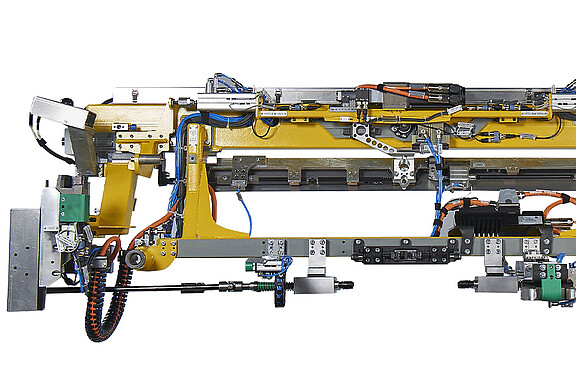

Fully or semi-automatic assembly of cockpit modules in the automotive industry requires the gripper tool to precisely position the assembly parts. As the laser scanners take over the measurement and positioning tasks, each cockpit module is individually adapted to the respective car body. Micro-Epsilon laser scanners are particularly suited for these measurement tasks due to their SMART functions and the particularly small and lightweight measuring head. They can be easily installed on a robot or manipulator. Using the SMART function, a parameterization of the sensors can be realized without further hardware components via Ethernet. In addition, measured values can be visualized and transmitted directly to the controller.

The precise scanCONTROL laser profile sensor evaluates the complete profile internally and transmits the measurement values via Ethernet to the control system. This enables the actuators to change the axis positions on the gripper in order to assembly the cockpit module in the ideal position in the car body. After the cockpit is fixed, the sensor determines the installation position of the cockpit which serves as proof of quality for each vehicle. For the entire process including the fitting of the cockpit, an extremely short cycle time of less than one minute is required. Measuring independent of surface conditions, the sensors provide reliable measurement values whether bright or dark paints are used, different gloss levels, variable surface structures and in unsteady ambient light conditions. The sensor automatically readjusts the exposure.