Aerospace

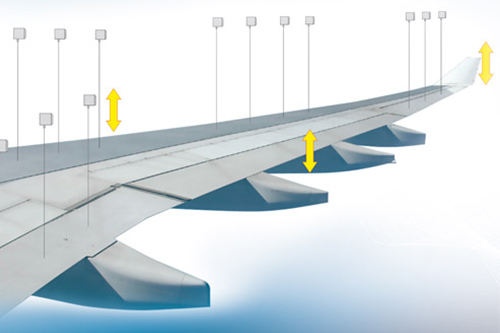

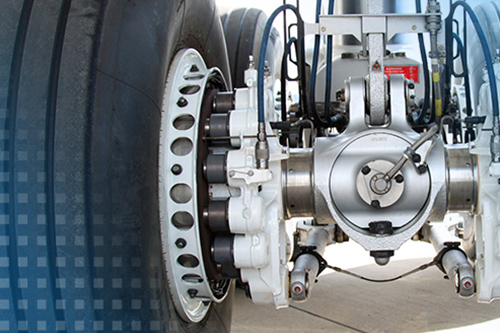

In aviation, the highest requirements are placed on installed components in terms of safety and reliability. This especially applies to sensors which are used in different places. For example in aircraft assembly, sensors from Micro-Epsilon ensure non-contact rivet hole measurement. Micro-Epsilon develops displacement and position sensors for aircraft measurement tasks landing gear, wing assembly, fuselage and engines, where they enable reliable determination of measurement values.