Width

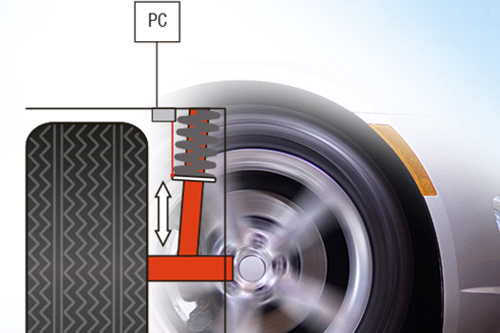

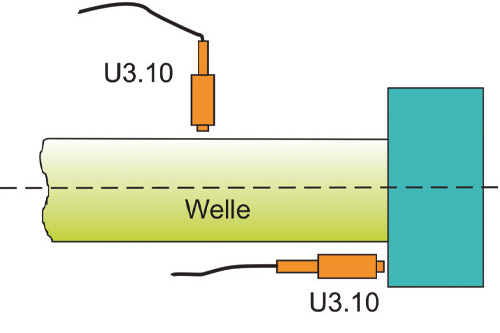

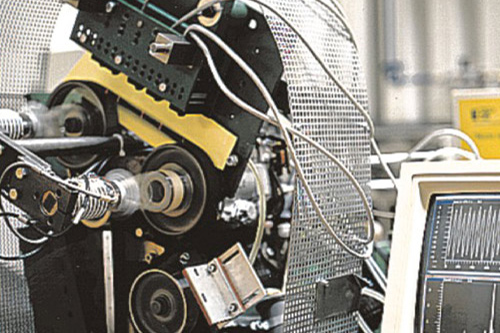

The width of an object is often an important aspect for dimension control. The width can in some circumstances be interpreted as thickness and can therefore be resolved using thickness measurement. Different measuring principles come into consideration for the width measurement depending on the size of the object. For large objects such as strip material or packages, the measurement data from two sensors are usually calculated together. Optical methods such as Thru-Beam laser micrometers, laser sensors or eddy current and capacitive sensors are suitable for this. One sensor which measures the object width with one measurement is often sufficient for smaller objects such as individually packaged goods. scanCONTROL split beam sensors or vision4A image processing systems are suitable for this.