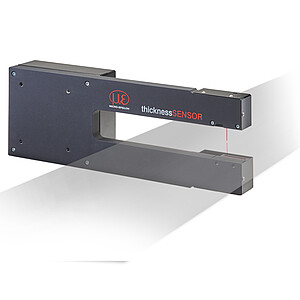

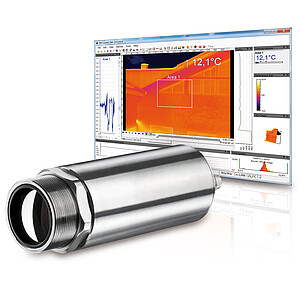

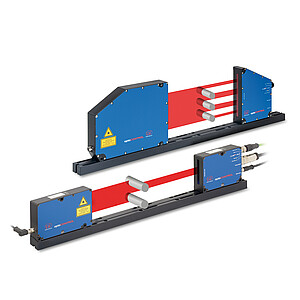

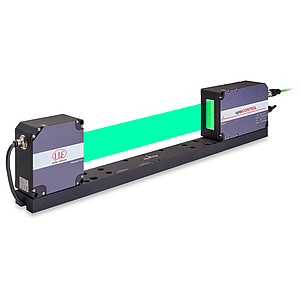

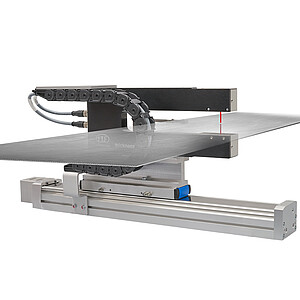

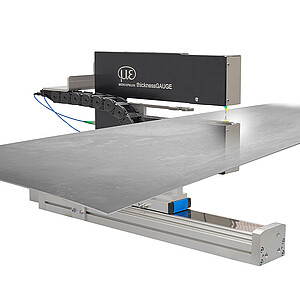

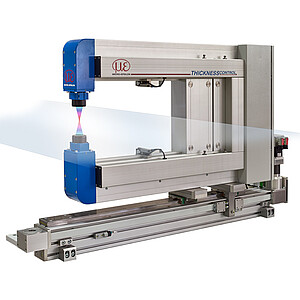

In semiconductor production, highest precision is essential. An important process step is the lapping of the blanks, which are thereby brought to a uniform thickness. In order to continuously control the thickness, the interferoMETER IMS5420 series white light interferometers were developed.

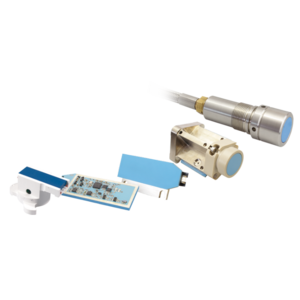

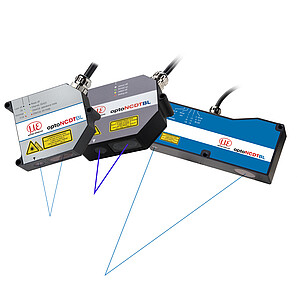

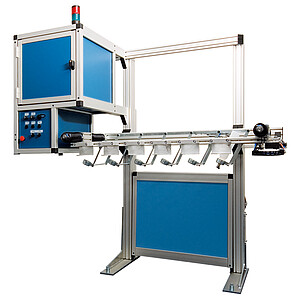

These each consist of a compact sensor and a controller housed in a robust industrial-grade enclosure. Active temperature control integrated in the controller ensures high stability of measurements.

The interferometer is available as either a thickness or a multi-peak thickness measuring system. The multi-peak thickness measuring system can measure the thickness of up to five layers, e.g., wafer thickness, air gap, film and coatings >50 µm. For thickness measurements in difficult environmental conditions, the IMS5420IP67 controller is available with IP67 protection rating and stainless steel housing as well as matching fiber optics and sensors.

Advantages

- Nanometer-accurate thickness measurement of undoped, doped and highly doped wafers

- Multi-peak: detection of up to 5 layers with an SI thickness of 0.05 up to 1.05 mm

- High resolution in z-axis of 1 nm

- Measuring rate up to 6 kHz for high speed measurements

- Ethernet / EtherCAT / RS422 / PROFINET / EtherNet/IP

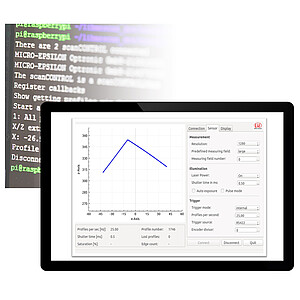

- Simple parameter set up via web interface