- Micro-Epsilon

- 2D/3D Measurement

2D/3D Measurement

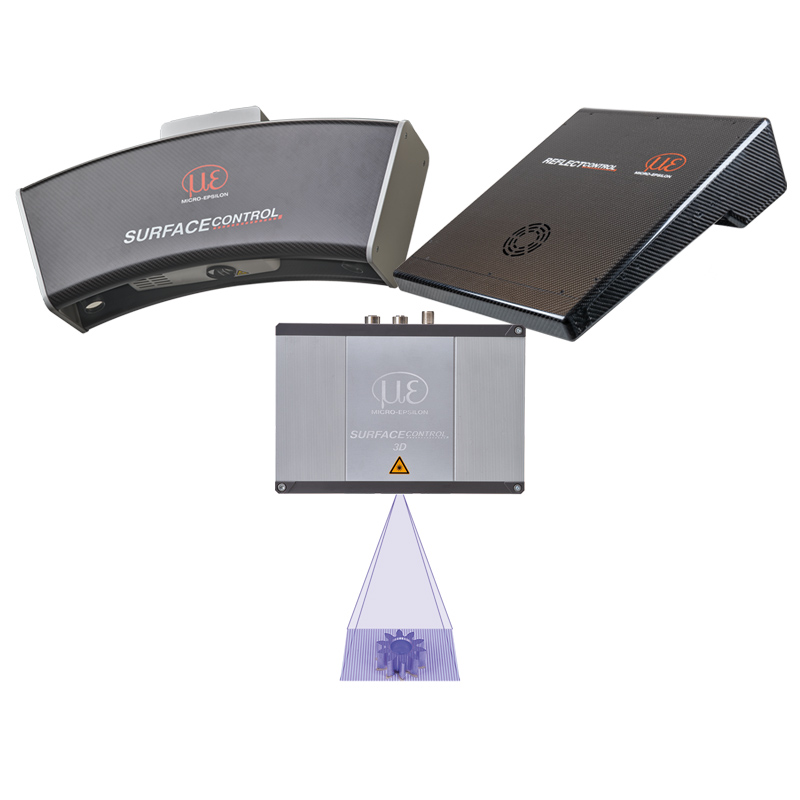

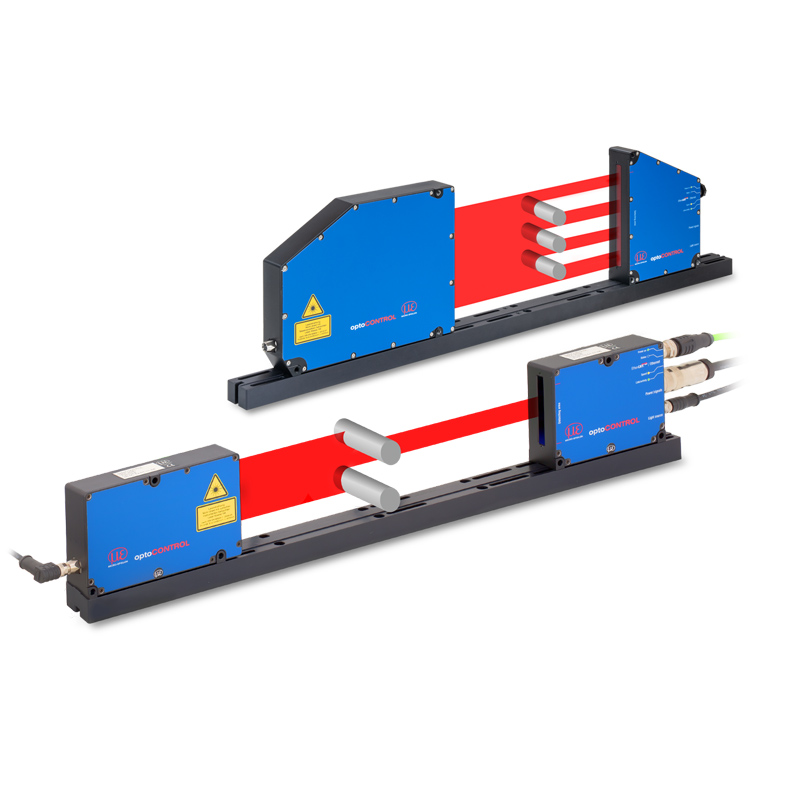

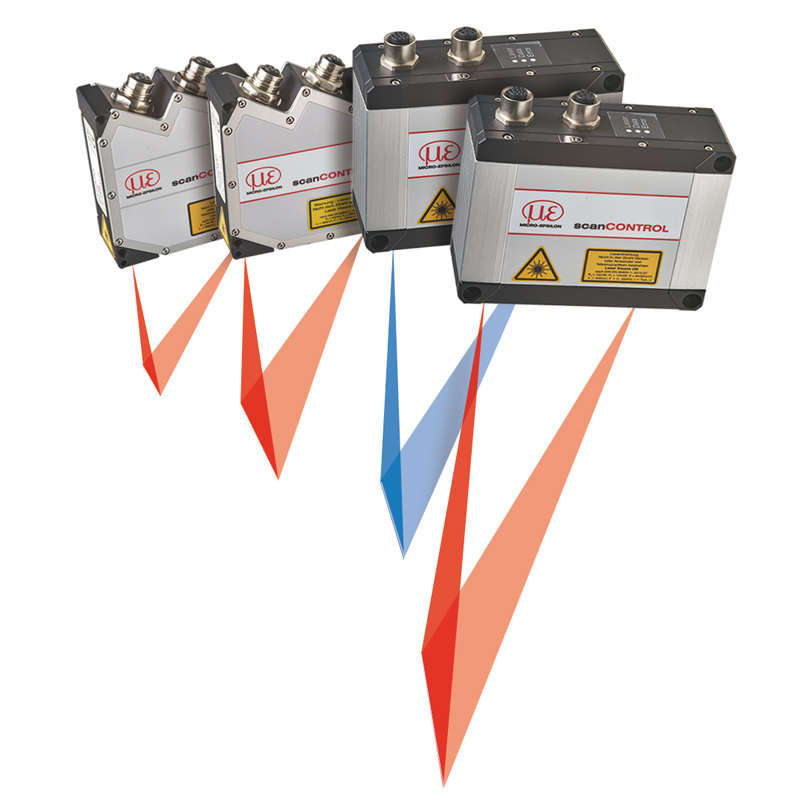

3D sensors for precise inline quality inspection

3D sensors from Micro-Epsilon are used for a wide range of measuring and inspection tasks. Evaluation and parameter setting are performed with the powerful 3DInspect software.

- 2D/3D Measurement

[{"activity":"US_ME_R0-NCSC","address":"8120 Brownleigh Dr.\r\nRaleigh, NC 27617","central":false,"comment":"CT, DC, DE, MA, MD, ME,\r\nNH, NJ, NY, PA, RI, VT","companyName":"Micro-Epsilon America | East Regional Office","countries":"220","deZip":"","email":"efrain.arredondo@micro-epsilon.com","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"919 787 9706","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1811},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":1653},"mobile":"919 400 3845","name":"Efrain Arredondo","phone1":"919 787 9707","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11343,"type":null,"uid":116,"usStates":"14,15,32,31,29,40,41,43,51,53,59,16","website":"www.micro-epsilon.com","worldwide":true},{"activity":"US_ME_R2-Mid-West","address":"1246 Woburn Dr\r\nLemont, IL 60439","central":false,"comment":"IL: 600-619,\r\nIN, KY, MI, OH,\r\nPA: 150-167,\r\nWI: 530-539, 541-545, 549, \r\nWV","companyName":"Micro-Epsilon America | Mid West Regional Office","countries":"220","deZip":"","email":"steve.sochowski@micro-epsilon.com","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"630 243-0997","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1812},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":1663},"mobile":"847 420 4781","name":"Steve Sochowski","phone1":"630 243-0980","phone2":"919 787 9707","pid":358,"products":"","regional":false,"showMail":false,"sorting":11344,"type":null,"uid":117,"usStates":"23,24,27,33,47,51,64,63","website":"www.micro-epsilon.com","worldwide":true},{"activity":"US_ME_R3-West","address":"San Clemente, CA 92673","central":false,"comment":"AK, CA, HI, NV, OR, WA","companyName":"Micro-Epsilon America | Western Regional Office","countries":"220","deZip":"","email":"jerry.carayanis@micro-epsilon.com","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"919 787 9706","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1813},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":1654},"mobile":"","name":"Jerry Carayanis","phone1":"310 729 0954","phone2":"919 787 9707","pid":358,"products":"","regional":false,"showMail":false,"sorting":11345,"type":null,"uid":118,"usStates":"2,12,21,39,49,62","website":"www.micro-epsilon.com","worldwide":true},{"activity":"US_ME_R4-South","address":"Denver, CO 80227","central":false,"comment":"AZ, CO, IA, ID,\r\nIL: 620-629, \r\nKS, LA, MN, MO, MT, ND, NE, NM, OK, SD, TX, UT,\r\nWI: 540, 546-548, \r\nWY","companyName":"Micro-Epsilon America | Central Regional Office","countries":"220","deZip":"","email":"friedrich.gebessler@micro-epsilon.com","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"919 787 9706","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1814},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":1655},"mobile":"919 412 3620","name":"Friedrich \u0022Fritz\u0022 Gebessler","phone1":"","phone2":"919 787 9707","pid":358,"products":"","regional":false,"showMail":false,"sorting":11347,"type":null,"uid":119,"usStates":"4,13,25,22,23,26,28,34,36,37,45,38,42,48,55,57,58,64,65","website":"www.micro-epsilon.com","worldwide":true},{"activity":"US_ME_R5-Southeast","address":"8120 Brownleigh Dr.\r\nRaleigh NC 27617","central":false,"comment":"AL, AR, FL, GA, MS, NC, \r\nSC, TN, VA","companyName":"Micro-Epsilon America | South East Regional Office","countries":"220","deZip":"","email":"tim.prentice@micro-epsilon.com","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"919 787 9706","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":1815},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":1656},"mobile":"","name":"Tim Prentice","phone1":"919 649 9805","phone2":"919 787 9707","pid":358,"products":"","regional":false,"showMail":false,"sorting":11348,"type":null,"uid":120,"usStates":"1,5,18,19,35,44,54,56,61","website":"www.micro-epsilon.com","worldwide":true},{"activity":"US_ME_R6-Northern","address":"4749 Bennett Drive, Suite J\r\nLivermore, CA 94551","central":false,"comment":"CA: 932, 934, 936 - 961 (Northern Cal)","companyName":"Micro-Epsilon America | Northern California Direct Office","countries":"220","deZip":"","email":"holger.kopp@micro-epsilon.de","emailCc":"","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"925 371 5673","hidePlz":false,"image":{"originalResource":{},"pid":358,"uid":61872},"internalNote":"","lName":"","map":{"originalResource":{},"pid":358,"uid":61871},"mobile":"","name":"Holger Kopp","phone1":"984 888 6555","phone2":"919 787 9707","pid":358,"products":"","regional":false,"showMail":false,"sorting":11349,"type":null,"uid":305,"usStates":"12","website":"www.micro-epsilon.com","worldwide":true},{"activity":"USREP_IRI","address":"9415 West Forest Home ave\r\nSuite 101\r\nWI 53130","central":false,"comment":"IL","companyName":"Instrumentation Resources","countries":"220","deZip":"","email":"steve.sochowski@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"815 520-0344","name":"Tim Fauser","phone1":"952-797-0220","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11293,"type":null,"uid":162,"usStates":"23","website":"www.irisensors.com","worldwide":true},{"activity":"USREP_TandM-Instruments","address":"15902 Soleil Ct\r\nAustin, TX 78734","central":false,"comment":"LA, OK, TX","companyName":"T\u0026M Instruments","countries":"220","deZip":"","email":"friedrich.gebessler@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"512-532-6130","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"T\u0026M Instruments","phone1":"512-772-1553","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11294,"type":null,"uid":171,"usStates":"28,48,57","website":"www.tandm.net","worldwide":true},{"activity":"USREP_Process-Technology_NM","address":"3301 Wellington Place\r\nFarmington, NM 87402","central":false,"comment":"NM","companyName":"Process Technology, Inc.","countries":"220","deZip":"","email":"friedrich.gebessler@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"505 948 3302","name":"Josh Gordon","phone1":"","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11295,"type":null,"uid":169,"usStates":"42","website":"www.process-tech.com","worldwide":true},{"activity":"USREP_Process-Technology","address":"4084 South 300 West\r\nSalt Lake City, UT 84107","central":false,"comment":"ID, MT, UT, WY","companyName":"Process Technology, Inc.","countries":"220","deZip":"","email":"friedrich.gebessler@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"385 322 3053","name":"Mike Hallenbeck","phone1":"801 264 1114","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11296,"type":null,"uid":168,"usStates":"22,37,58,65","website":"www.process-tech.com","worldwide":true},{"activity":"USREP_Analectro","address":"3219 Route 38, Suite 2\r\nMt. Laurel, NJ 08054","central":false,"comment":"DC, DE, MD, NJ\r\nPA: 168 - 196","companyName":"Analectro","countries":"220","deZip":"","email":"efrain.arredondo@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"856 795 4597","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Al Reithmeier, Kevin Corcoran","phone1":"856 795 6676","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11297,"type":null,"uid":154,"usStates":"16,15,31,41,51","website":"www.analectro.com","worldwide":true},{"activity":"USREP_Dempsco","address":"7015 Corporate Way\r\nDayton, OH 45459","central":false,"comment":"KY, IN, WV, \r\nOH: 430-433, 437-459\r\nPA: 150-167","companyName":"Dempsco","countries":"220","deZip":"","email":"steve.sochowski@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"937 434 8860","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Kurt Jacoby, Chris Jacoby","phone1":"937 436 1000","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11298,"type":null,"uid":160,"usStates":"27,24,63,47,51","website":"www.dempsco.com","worldwide":true},{"activity":"USREP_Preferred_Technical_Resources","address":"28525 Beck Road, Suite 109\r\nWixom, MI 48393","central":false,"comment":"MI, OH: 434 - 436","companyName":"Preferred Technical Resources","countries":"220","deZip":"","email":"steve.sochowski@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"248 668 9059","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Philip Theaker, John Callaghan","phone1":"248 668 9051","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11299,"type":null,"uid":167,"usStates":"33,47","website":"www.ptrsales.com","worldwide":true},{"activity":"USREP_MCT_RAM","address":"2 W Main St, Suite 300\r\nVictor, NY 14564","central":false,"comment":"NY 120 - 123, 128 - 149","companyName":"MCT\/RAM - Corporate Office","countries":"220","deZip":"","email":"efrain.arredondo@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"585 461 2114","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"John Saporito","phone1":"585 461 2110","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11300,"type":null,"uid":165,"usStates":"43","website":"www.mctram.com","worldwide":true},{"activity":"USREP_MCT_RAM1","address":"4 Marina Lane\r\nE. Patchogue, NY 11772","central":false,"comment":"NY 100 - 119, 124 - 127","companyName":"MCT\/RAM - Lower New York and New York City","countries":"220","deZip":"","email":"efrain.arredondo@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"585-461-2114","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"John Gustafson","phone1":"631-286-7374","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11301,"type":null,"uid":166,"usStates":"43","website":"www.mctram.com","worldwide":true},{"activity":"USREP_IRI","address":"9415 West Forest Home ave\r\nSuite 101\r\nWI 53130","central":false,"comment":"WI: 530 - 539, 541 - 545, 549","companyName":"Instrumentation Resources","countries":"220","deZip":"","email":"steve.sochowski@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"414- 458-9325","name":"Jon Korus","phone1":"952-797-0220","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11302,"type":null,"uid":163,"usStates":"64","website":"www.irisensors.com","worldwide":true},{"activity":"USREP_IRI","address":"13774 Reimer Drive North \r\nMaple Grove, MN 55311","central":false,"comment":"IA, KS, MN, MO, ND, NE, SD,\r\nWI: 540, 546 - 548","companyName":"Instrumentation Resources","countries":"220","deZip":"","email":"friedrich.gebessler@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"952 797 0223","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Tony Marquette","phone1":"952 797 0220","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11303,"type":null,"uid":164,"usStates":"25,26,34,36,45,38,55,64","website":"www.irisensors.com","worldwide":true},{"activity":"USREP_Equipoise","address":"4059 N Haight Ave\r\nPortland, OR 97227-1332","central":false,"comment":"OR, WA","companyName":"Equipoise Technologies, LLC","countries":"220","deZip":"","email":"jerry.carayanis@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Ed Querfeld","phone1":"503 708 9969","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11304,"type":null,"uid":161,"usStates":"49,62","website":"www.equipoisetech.com","worldwide":true},{"activity":"USREP_CASECO","address":"508 Queens Court\r\nFranklin, TN 37064","central":false,"comment":"AL, AR, MS, TN\r\nFL: 324 - 325","companyName":"CASECO","countries":"220","deZip":"","email":"tim.prentice@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"615 591-7399","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"615 210-7311","name":"Tim DiPeri","phone1":"615 591-7399","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11305,"type":null,"uid":159,"usStates":"1,5,35,56,18","website":"www.caseco-inc.com","worldwide":true},{"activity":"USREP_CAL_Industrial_Sales_Co","address":"4749 Bennett Drive, Suite J\r\nLivermore, CA 94551","central":false,"comment":"CA: 932, 934, 936 - 961 (Northern Cal)\r\nNV: 892 - 898","companyName":"CAL Industrial Sales Co.","countries":"220","deZip":"","email":"jerry.carayanis@micro-epsilon.com","emailCc":"me-usa@micro-epsilon.com","fName":"","fallback":false,"fallbackPagesearch":false,"fax":"925 371 5673","hidePlz":false,"image":null,"internalNote":"","lName":"","map":null,"mobile":"","name":"Dave Richardson, Bob McCartney","phone1":"925 371 8125","phone2":"","pid":358,"products":"","regional":false,"showMail":false,"sorting":11306,"type":null,"uid":158,"usStates":"39,12","website":"www.calindustrial.com","worldwide":true}]

Contact

Efrain Arredondo

Micro-Epsilon America | East Regional Office

CT, DC, DE, MA, MD, ME, NH, NJ, NY, PA, RI, VT

Contact form

Steve Sochowski

Micro-Epsilon America | Mid West Regional Office

IL: 600-619, IN, KY, MI, OH, PA: 150-167, WI: 530-539, 541-545, 549, WV

Contact form

Jerry Carayanis

Micro-Epsilon America | Western Regional Office

AK, CA, HI, NV, OR, WA

Contact form

Friedrich "Fritz" Gebessler

Micro-Epsilon America | Central Regional Office

AZ, CO, IA, ID, IL: 620-629, KS, LA, MN, MO, MT, ND, NE, NM, OK, SD, TX, UT, WI: 540, 546-548, WY

Contact form

Tim Prentice

Micro-Epsilon America | South East Regional Office

AL, AR, FL, GA, MS, NC, SC, TN, VA

Contact form

Holger Kopp

Micro-Epsilon America | Northern California Direct Office

CA: 932, 934, 936 - 961 (Northern Cal)

Contact form

Josh Gordon

Process Technology, Inc.

NM

Contact form

Kurt Jacoby, Chris Jacoby

Dempsco

KY, IN, WV, OH: 430-433, 437-459 PA: 150-167

Contact form

Philip Theaker, John Callaghan

Preferred Technical Resources

MI, OH: 434 - 436

Contact form

John Gustafson

MCT/RAM - Lower New York and New York City

NY 100 - 119, 124 - 127

Contact form

Tony Marquette

Instrumentation Resources

IA, KS, MN, MO, ND, NE, SD, WI: 540, 546 - 548

Contact form

Dave Richardson, Bob McCartney

CAL Industrial Sales Co.

CA: 932, 934, 936 - 961 (Northern Cal) NV: 892 - 898

Contact form