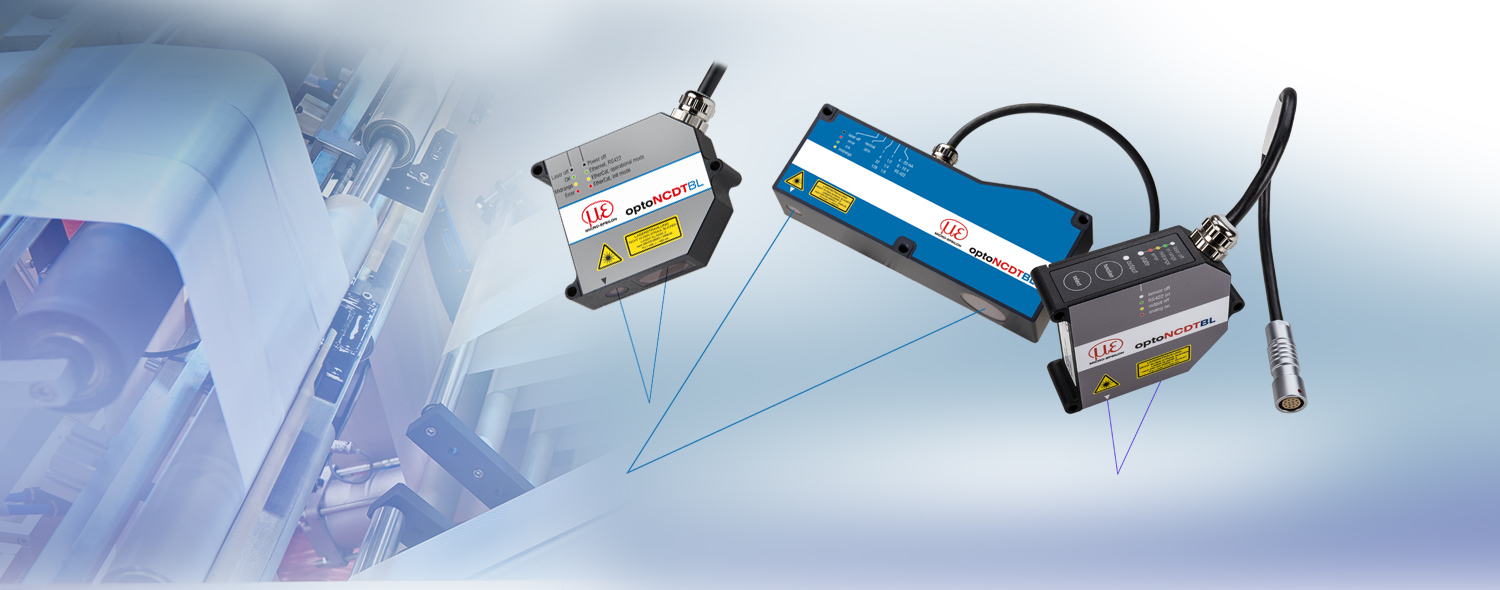

Blue Laser triangulation sensors for difficult surface types

The optoNCDT BL models are equipped with a blue laser diode and are used when standard sensors with a red laser diode are operating at their performance limits. Due to its shorter wavelength, the blue laser does not penetrate the target surface, projecting a small light spot on the surface and therefore providing stable and precise results. As Blue Laser sensors are equipped with a special filter, they are insensitive to highly emitting objects such as glowing metals. Blue Laser sensors are preferably used with measurements on organic and (semi-)transparent objects, as well as for red-hot glowing metals.

High Precision Blue Laser Displacement Sensor

The optoNCDT2300-2DR is the new model in the high performance optoNCDT 2300 range. The beam path is designed for direct reflection and will find applications in the measurement of high-gloss, shiny and reflecting surfaces. Blue Laser technology from Micro-Epsilon and its optical arrangement result in a laser sensor that is extremely sensitive to changes in distance, which enables very high measurement accuracies. The new model is used in consumer electronics production (e.g. smartphones, tablets and displays), industrial applications and for the production and processing of semiconductors.

Patented Blue Laser Technology

Measurement tasks involving blue laser sensors on red-hot glowing objects exceeding 700 °C and transparent objects such as plastics, adhesives and glass are patented by Micro-Epsilon. The optoNCDT Blue Laser models achieve excellent signal stability and thus precise measurement results on these surfaces.

The new Blue Laser Technology enables the sensor to measure absolutely precisely and reliably on glowing metals and glowing silicon. The blue-violet laser offers decisive advantages here. Even when measuring organic materials such as veneers, wood or skin, the blue laser also contributes to high precision. While allowing higher stability, the blue laser light does not penetrate the measuring object due to the shorter wavelength of the blue-violet laser.

optoNCDT 1710BL blue laser sensors are designed for fast displacement, distance and position measurements on glowing metals. The sensors offer new high-performance lenses, laser control and evaluation algorithms.

- Measuring ranges (mm): 50 | 1000

- Linearity from 50µm

- Resolution max. 7.5µm

- Configurable measuring rate up to 2.5kHz

- Analogue and digital outputs

- Compact with integrated controller

- Real-time compensation for changing surfaces (RTSC)

- Freely programmable limit switches

- Data sheet optoNCDT 1710BL (pdf, 2.81 MB)

- Setup Guide optoNCDT 1700, 1700LL, 1700BL (pdf, 876.30 KB)

- Setup Guide optoNCDT 1700, 1700BL (pdf, 1.17 MB)

- Operating Instructions optoNCDT 1700 (pdf, 3.24 MB)

- CAD file 3D-model sensor "ILD1700", STEP (zip, 1.98 MB)

- CAD file 3D-model sensor "ILD1710-1000 / ILD1710-1000BL", STEP (zip, 423.43 KB)

- CAD file 3D-model: Protection housing optoNCDT 17x0 /23x0 - Size S, STEP (zip, 496.43 KB)

- CAD file 3D-model: Protection housing - optoNCDT 17x0 /23x0 Size M, STEP (zip, 1.21 MB)

- ILD1700 Tool V3.6.0 (zip, 11.43 MB)

- MEDAQLib V5.3.1 (zip, 22.86 MB)

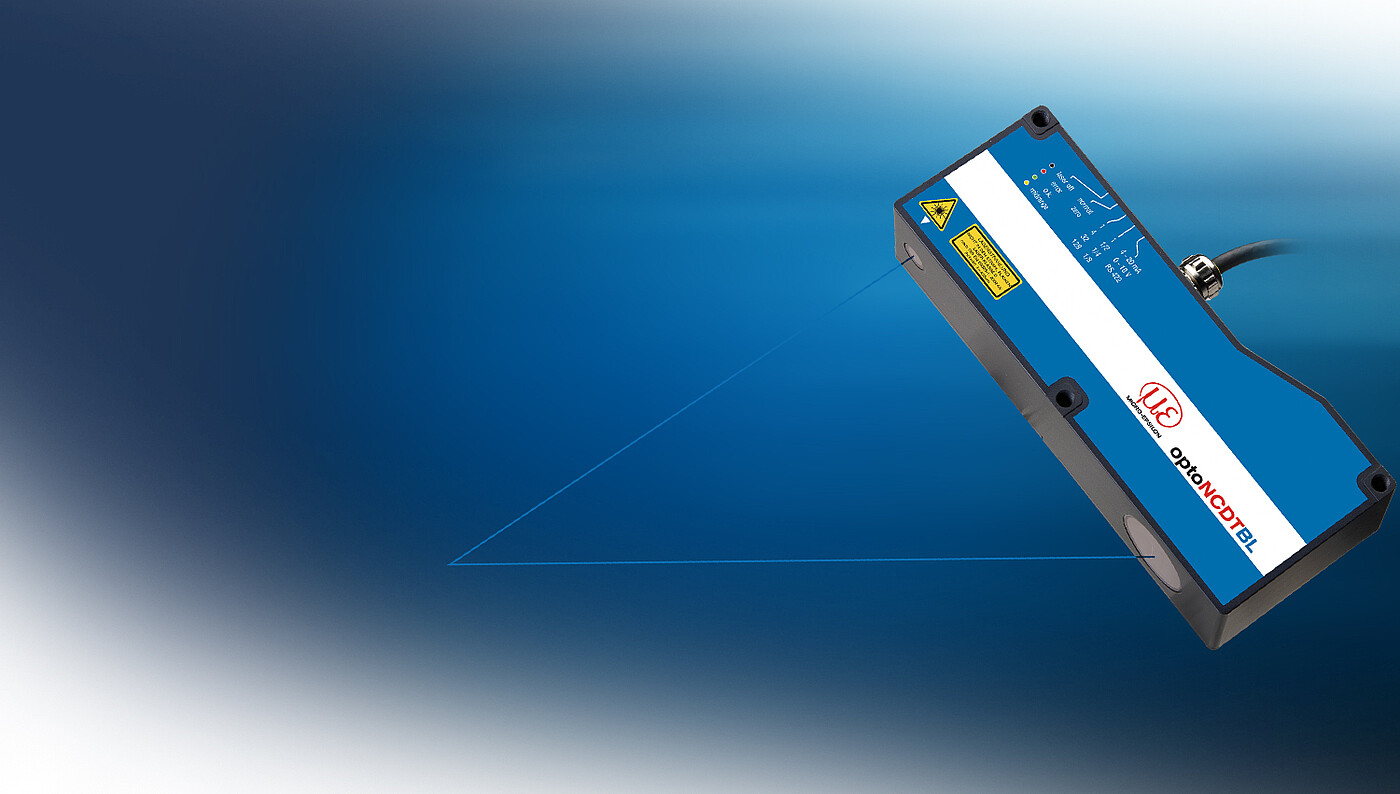

optoNCDT 1750BL Blue Laser sensors are designed for high speed displacement, distance and position measurements. They are equipped with new high performance lenses, laser control and evaluation algorithms to ensure precise measurements on different surfaces and materials. The Blue Laser Technology patented by Micro-Epsilon offers decisive advantages compared to red-diode laser sensors. Since the blue laser point does not penetrate the surface, the target is sharply imaged onto the sensor element. This makes it possible to achieve high resolution and reliable signal stability.

- Measuring ranges (mm): 20 | 200 | 500 | 750

- Adjustable measuring rate up to 7.5 kHz

- Linearity from 12 µm

- Repeatability max. 0.8 µm

- Analog and digital output

- Compact design with integrated controller

- Real-time adaption to changing surfaces (RTSC)

- Predefined and individual presets in web interface

The new Blue Laser Technology enables the sensor to measure absolutely precisely and reliably on glowing metals and glowing silicon. The blue-violet laser offers decisive advantages here. Even when measuring organic materials such as veneers, wood or skin, the blue laser also contributes to high precision. While allowing higher stability, the blue laser light does not penetrate the measuring object due to the shorter wavelength of the blue-violet laser.

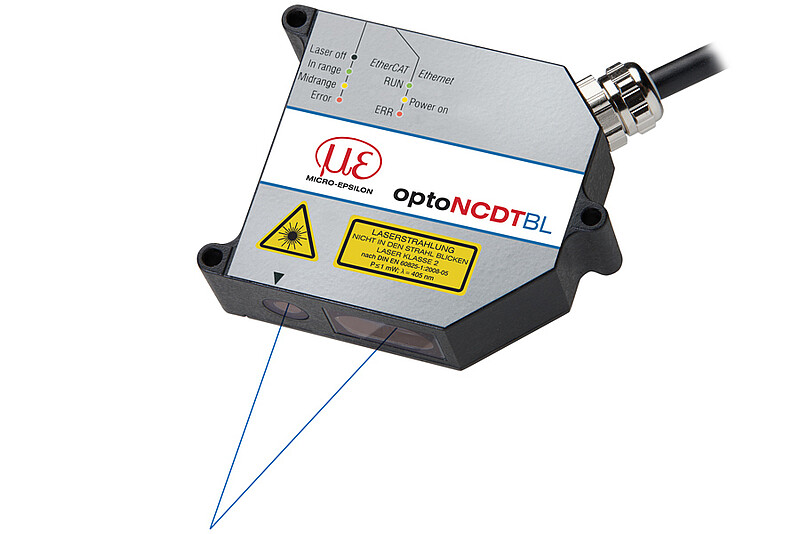

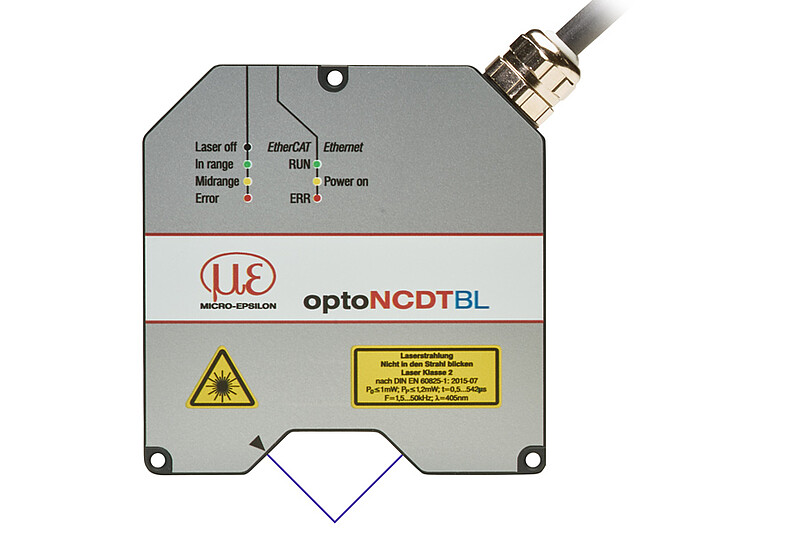

The high-end optoNCDT 2300BL series operates at a measuring rate up to 49kHz and is therefore ideally suited to precise measurements of fast moving objects. As the controller is completely integrated into the sensor housing, the sensor is ideal for installation in restricted spaces.

Operation is via a web interface that is addressed via an Ethernet interface. This web interface enables making settings for the processing of measured values and signals, e.g., peak selection, filter and masking features for the video signal.

- Measuring range (mm): 2 | 5 | 10 | 50

- Linearity from 0.6µm

- Resolution max. 0.03µm

- Adjustable measurement rate up to 49.140 kH

- Integrated controller

- Outputs: Ethernet, EtherCAT, RS422, Profinet, EtherNet/IP

- Analogue output via C-Box

- Fast adaption to rapidly changing surface types due to Advanced RTSC

- Data sheet optoNCDT 2300BL (pdf, 3.91 MB)

- Setup Guide optoNCDT 2300 (pdf, 1.07 MB)

- Operating Instructions optoNCDT 2300 (pdf, 13.83 MB)

- Setup Guide 1-Channel RS422/USB Converter IF2001/USB (pdf, 2.20 MB)

- Frequently asked questions about Java (pdf, 762.63 KB)

- CAD file 3D-model "ILD2300", STEP (zip, 730.32 KB)

- CAD file 3D-model: Protection housing optoNCDT 17x0 /23x0 - Size S, STEP (zip, 496.43 KB)

- CAD file 3D-model: Protection housing - optoNCDT 17x0 /23x0 Size M, STEP (zip, 1.21 MB)

- optoNCDT 23x0 EtherCAT XML (V1.9) (zip, 1.11 MB)

- MEDAQLib V5.3.1 (zip, 22.86 MB)

The optoNCDT 2300-2DR high precision laser triangulation sensor is designed for measurements on reflective and shiny targets. Due to its blue laser light, the measurement signal is extremely stable, i.e. the sensor measures down to the nanometer range. An extremely small laser spot size enables reliable detection of very small objects.

The sensor is, for example, used for thickness measurement of flat glass, assembly monitoring of extremely small parts and for distance measurements on annealed glass.

Operation is via a web browser that is addressed via an Ethernet interface. This interface enables making settings for the processing of measured values and signals, e.g., peak selection, filtering and masking features for video signals.

- Measuring range 2mm

- Linearity 0.6µm

- Resolution 30nm

- Adjustable measuring rate up to 49kHz

- Integrated controller

- In/Out: RS422, Ethernet, EtherCAT, Profinet, EtherNet/IP

- Analog output via C-Box/2A

- Fast adaption to rapidly changing surface types using Advanced RTSC