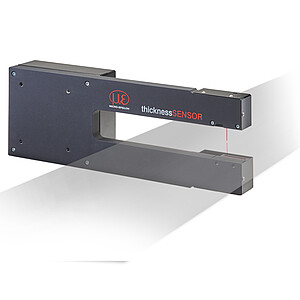

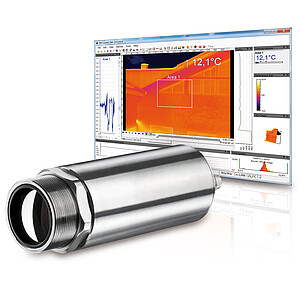

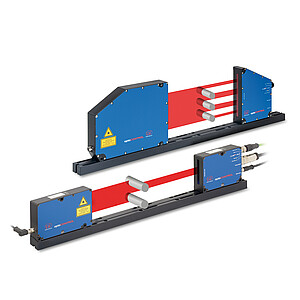

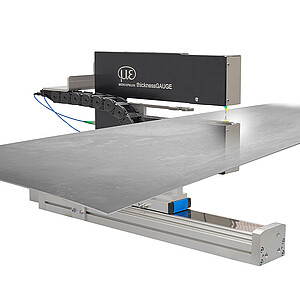

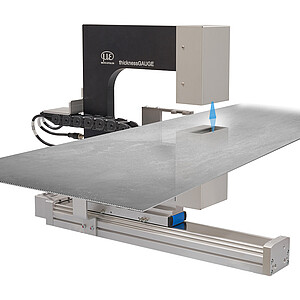

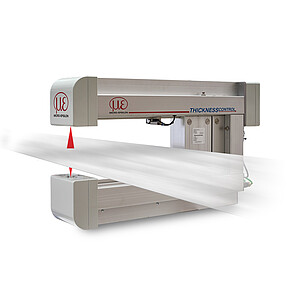

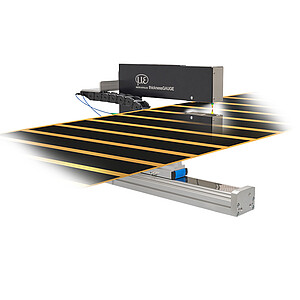

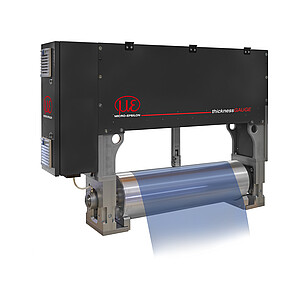

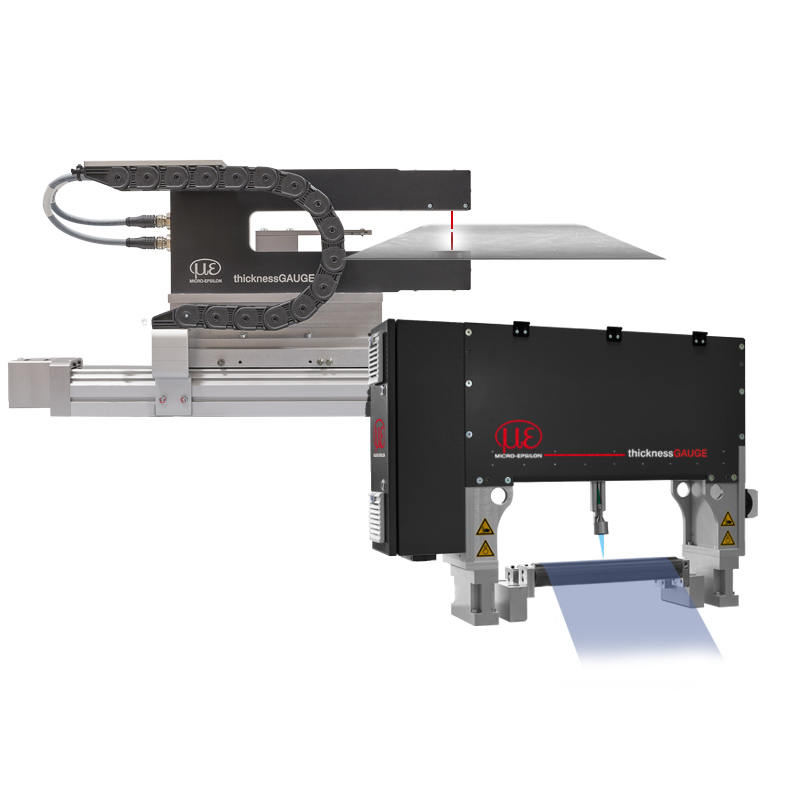

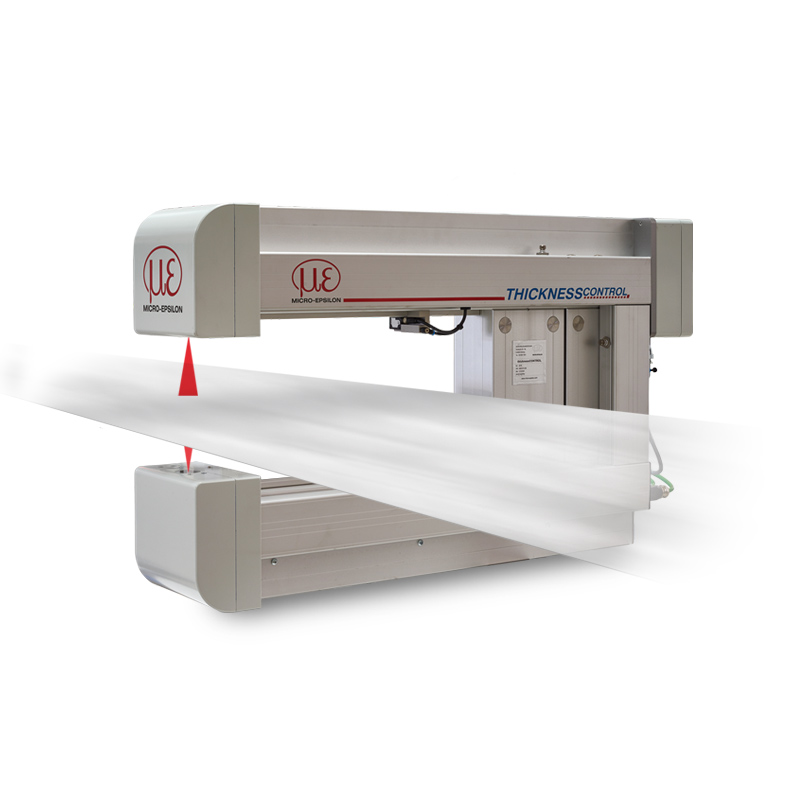

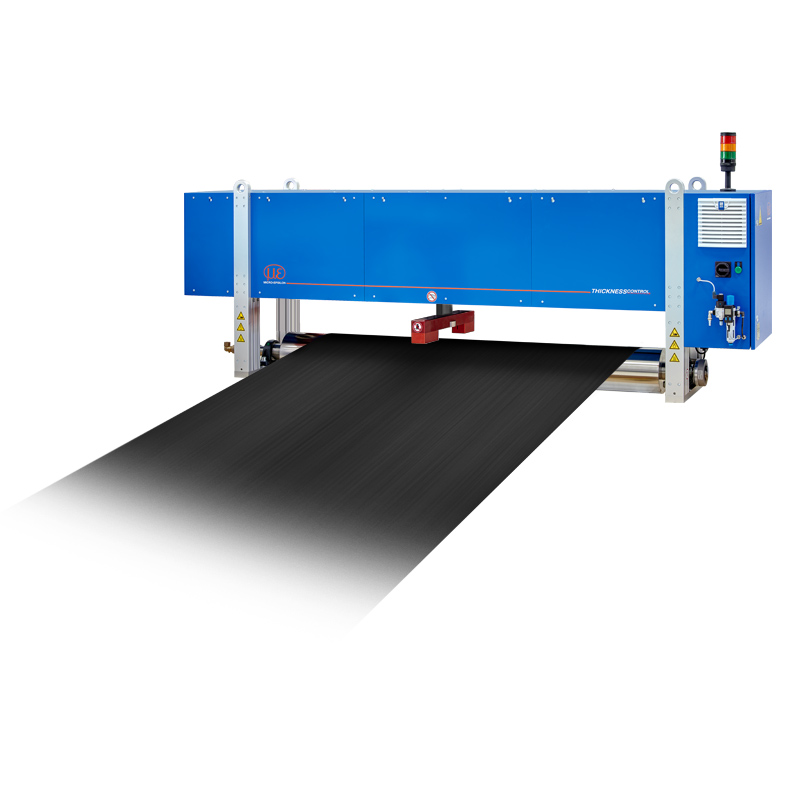

thicknessGAUGE sensor systems are used for precise thickness measurements of strip materials, plates and sheets up to 50 mm. Several models with different sensor types, measuring ranges and measuring widths enable inline thickness measurements of different materials and surfaces based on an unmatched price/performance ratio.

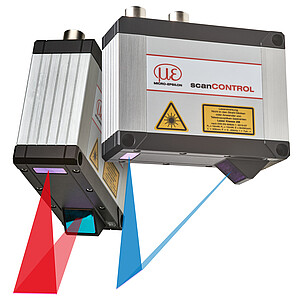

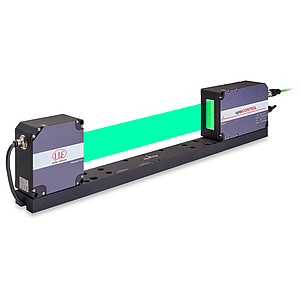

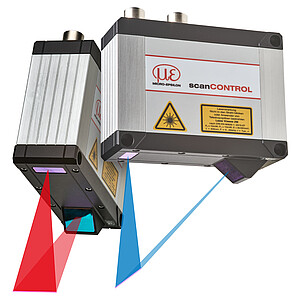

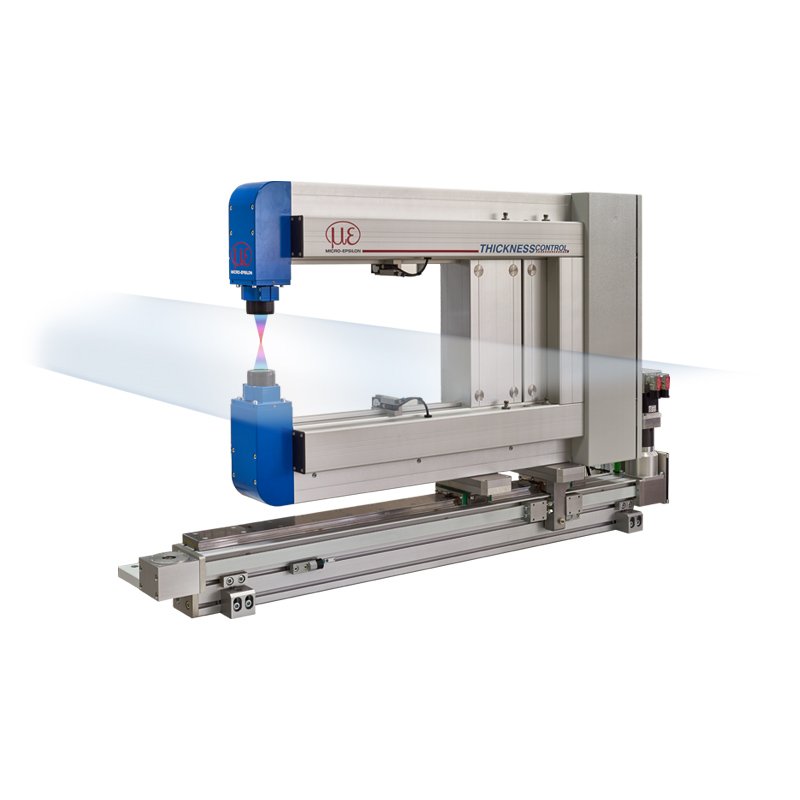

This fully assembled system comprises a stable frame on which two optical distance sensors are fixed, which detect the thickness of the measuring object according to the difference principle. The sensors are perfectly aligned to each other in terms of their mounting condition. Furthermore, thickness calibration at the factory enables high precision thickness measurements.

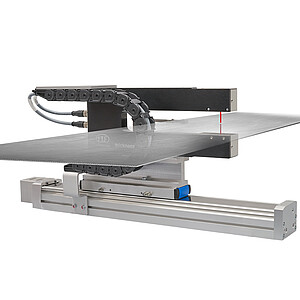

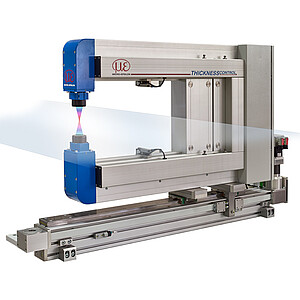

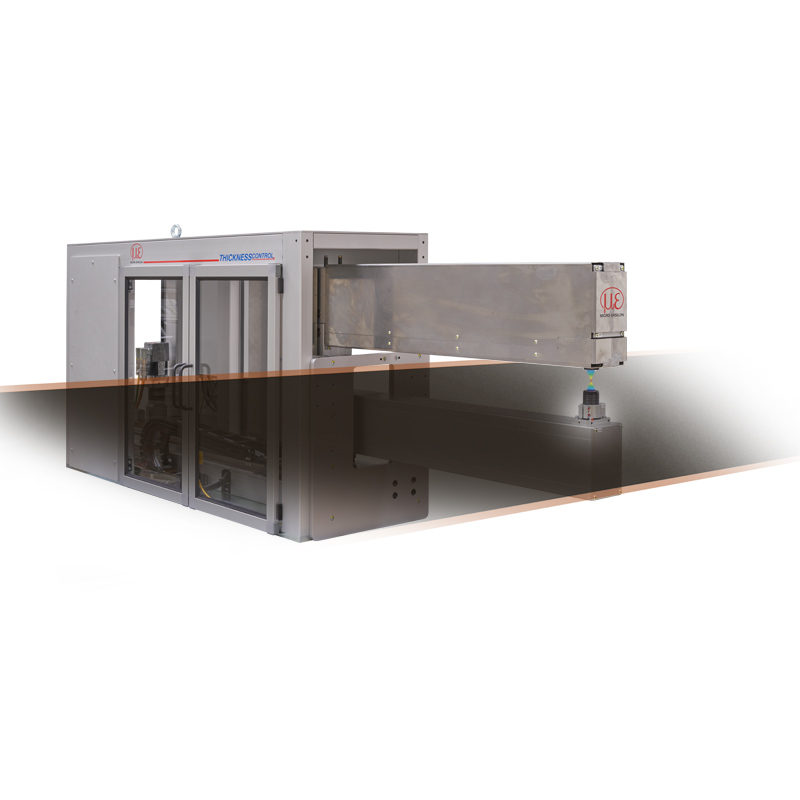

A linear axis moves the sensor system from the parking position to the measuring position. A measurement standard for fully automatic calibration is in the parking position.